Microencapsulation modification method of laser direct structuring additive, product and application thereof

A technology of laser direct structuring and microencapsulation, which is used in the preparation of laser direct structuring materials and the microencapsulation modification of laser direct structuring additives. problem, to achieve the effect of improving thermal stability and enhancing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0043] Preparation of melamine prepolymer: Add melamine and formaldehyde at a molar ratio of 1:3 to a three-necked flask, stir to dissolve melamine in aqueous formaldehyde (concentration of aqueous formaldehyde is 37%), and use 10% Na 2 CO 3 Adjust the pH value of the system to 8-9, and keep the reaction at 80°C for 1.5h to prepare the melamine prepolymer;

[0044] Preparation of microcapsules: Add an appropriate amount of distilled water and a certain amount of copper chromium oxide into a three-necked flask, add an appropriate amount of melamine prepolymer after rapid stirring, and keep the ratio of copper chromium oxide and melamine prepolymer at 1 / 1 , use 10% HAc to adjust the pH value of the system to 5-6, then stir at the set speed, slowly raise the temperature to 75 ° C, keep warm for 2 hours, take it out, put it in an ice-water bath to cool to room temperature, and use 10% Na 2 CO 3 Adjust the pH to neutral, filter, wash, and vacuum-dry to obtain microcapsule sample...

Embodiment 1

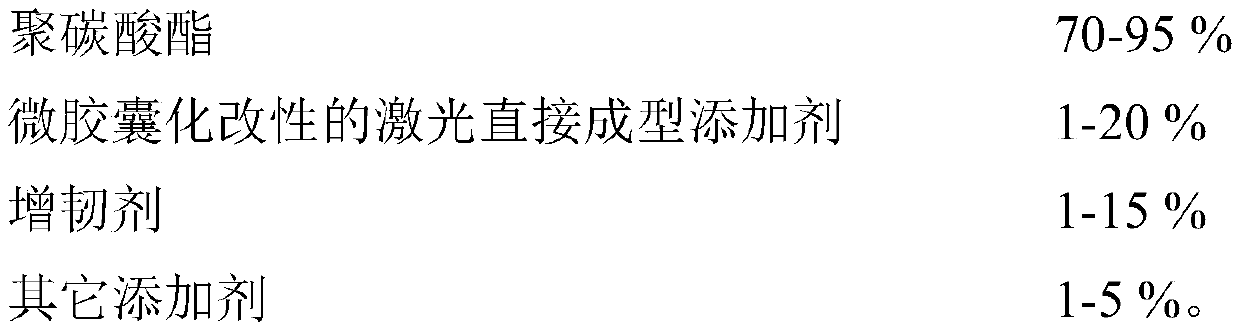

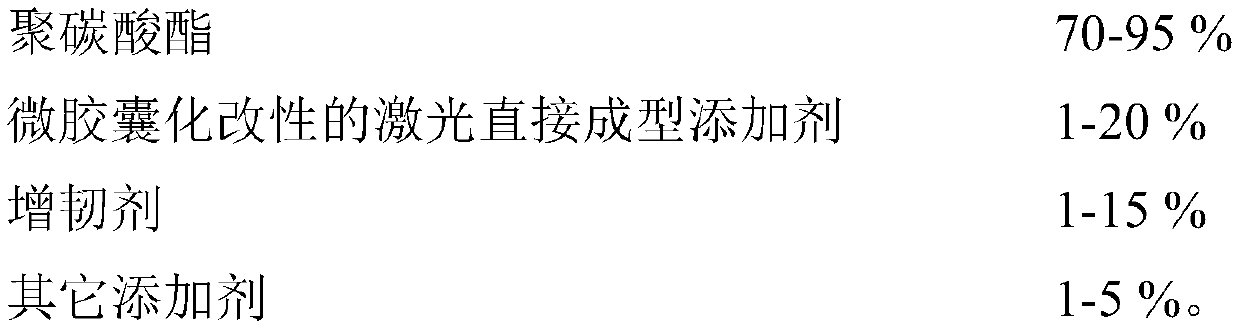

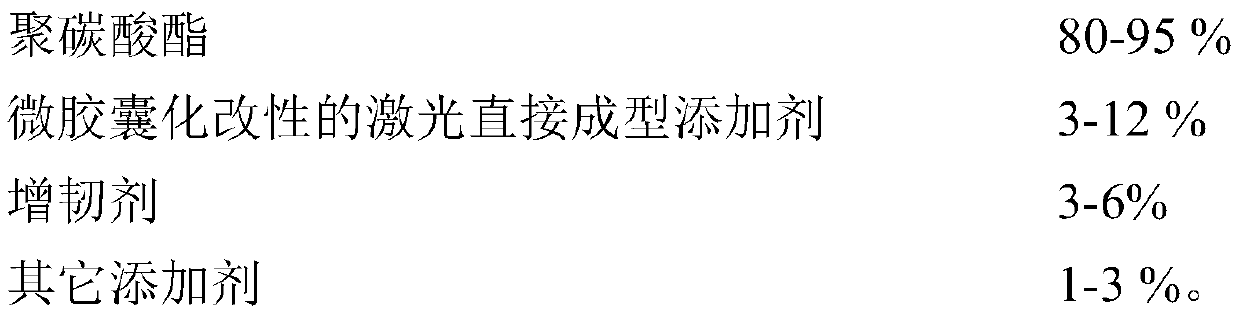

[0047] In embodiment 1, raw material total amount is 6kg, and by weight percentage, component is as follows:

[0048] Component % by weight, % polycarbonate 91 Modified LDS additive 3 Toughener 5 other additives 1

Embodiment 2

[0049] In embodiment 2, raw material total amount is 5.5kg, and by weight percentage, component is as follows:

[0050] Component % by weight, % polycarbonate 89 Modified LDS additive 5 Toughener 5 other additives 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com