Rh-based catalyst loaded on titanium dioxide nanorod as well as preparation method and application thereof

A technology of titanium dioxide and nanorods, applied in the field of noble metal Rh catalysts and their preparation, can solve the problems of low activity of Rh-based catalysts, poor ethanol selectivity, and easy deactivation by hydrogenation, so as to improve catalytic activity, catalytic performance, and promote activation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

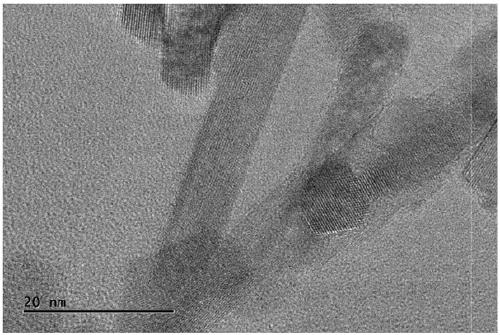

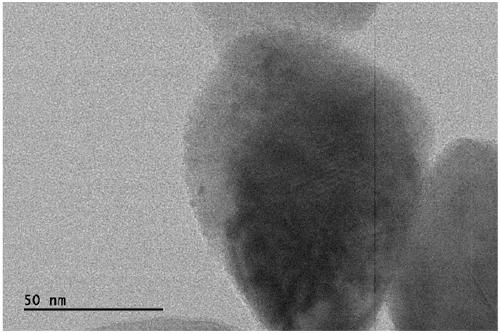

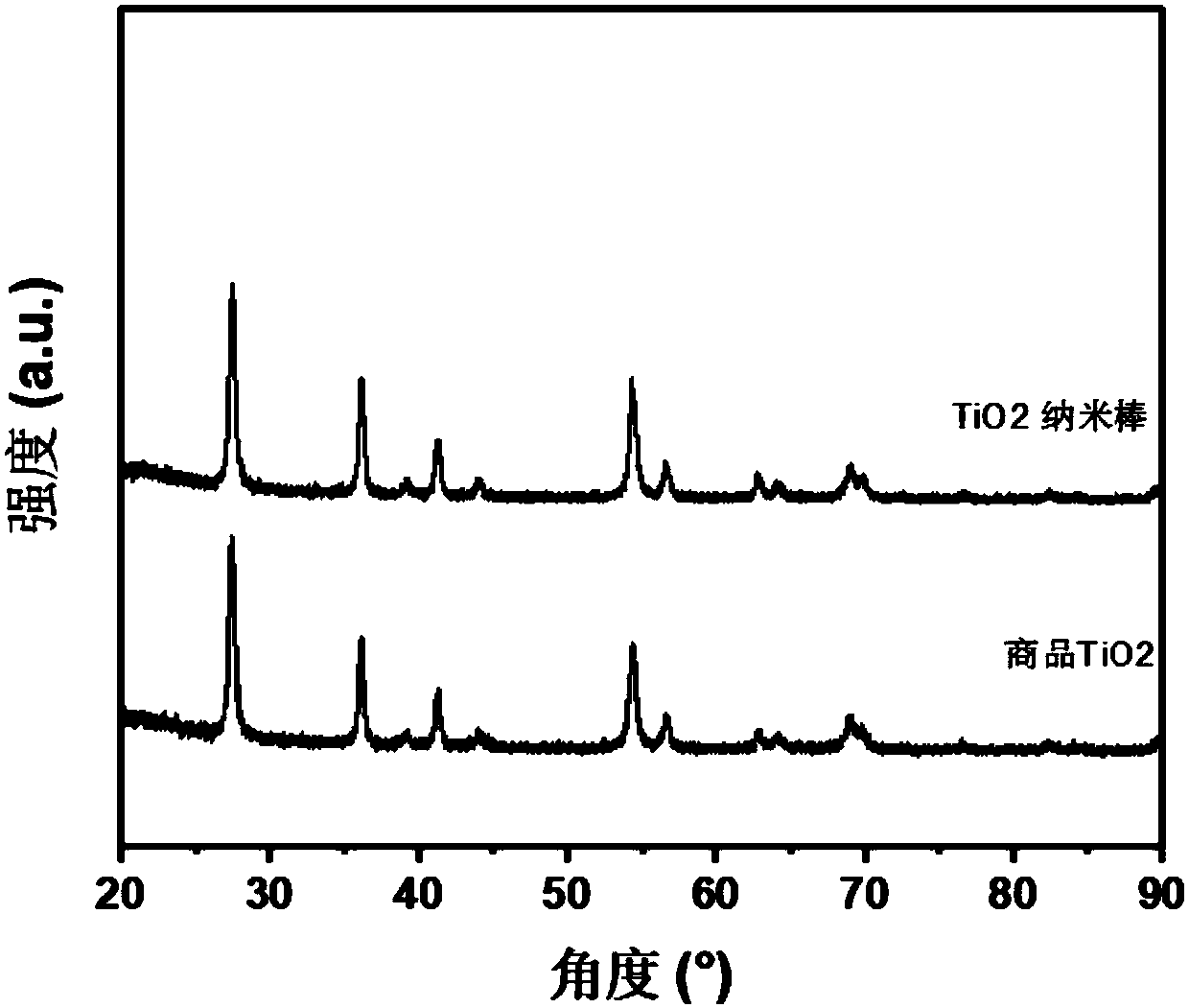

[0053] (1) Take 11.3822g titanium chloride (TiCl 4 ) into 20ml of deionized water, then add 35ml of concentrated nitric acid, heat up to 170 degrees centigrade from room temperature at a rate of 5 degrees centigrade per minute and insulate and react for 20 hours, let it stand for washing, and dry the product after centrifugal washing of the reaction system Dry at 100°C for 12 hours, then raise the temperature from room temperature to 500°C at a rate of 5°C per minute and keep it roasted for 4 hours to obtain supported TiO 2 Nano stave;

[0054] (2) Take 0.0953g iron nitrate (Fe(NO 3 ) 3 9H 2 O) and 0.0163g lithium nitrate (LiNO 3 ), adding RhCl with a concentration of 0.020g / mL 3 1.25mL of aqueous solution to form a metal solution;

[0055] (3) 1g of prepared TiO 2 The nanorods were immersed in the above metal solution, ultrasonicated for 1 hour, dried at room temperature for 12 hours, and dried at 80°C for 12 hours;

[0056] (4) The solid obtained in (3) is heated fro...

Embodiment 2

[0070] React with embodiment 1 method, and its difference is only in the ferric nitrate (Fe(NO) of step (2) 3 ) 3 9H 2 The quality of O) is 0.3812g, and Fe mass percent composition is 5% in the obtained catalyst.

Embodiment 3

[0072] Adopt embodiment 1 method to react, its difference is only in the ferric nitrate (Fe(NO) of step (2) 3 ) 3 9H 2 The quality of O) is 0.1906g, and the Fe mass percentage content is 2.5% in the obtained catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com