Color master batch for membranes and preparation method of color master batch

A color masterbatch and masterbatch technology, applied in the field of color masterbatch, can solve problems such as reducing the quality of film products and affecting film production, and achieve the effects of maintaining light stability, inhibiting light energy damage, and improving the casting and embossing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

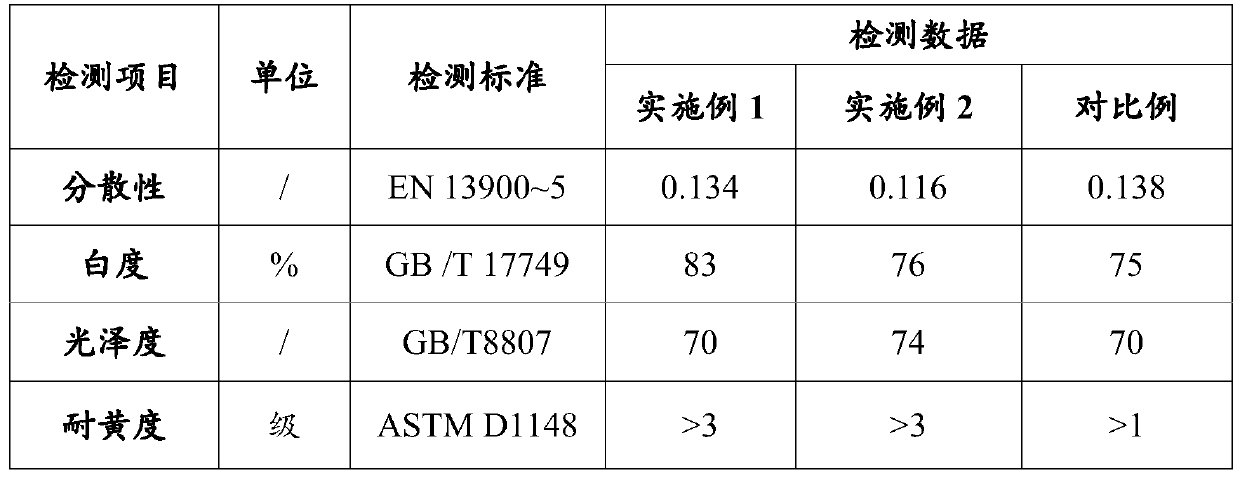

Examples

preparation example Construction

[0036] The present invention also proposes a preparation method of color masterbatch for film, comprising the following steps:

[0037] Dust removal: use compressed air to remove dust from raw materials;

[0038] Mixing: high-speed shear mixing of dust-removed raw materials by high-speed mixer;

[0039] Extrusion molding: use a twin-screw extruder to melt and plasticize the mixed raw materials, and extrude them to form strips;

[0040] Cooling and cutting: After cooling the strips, they are pelletized to obtain masterbatches;

[0041] Screening: put the color masterbatch into a vibrating sieve, retain the color masterbatch with a particle size range of 2-10mm, and obtain the color masterbatch for the film.

[0042] Specifically, the dust removal treatment in the technical solution of the present invention is mainly to prevent the raw materials of the color masterbatch from containing dust impurities, which will pollute the quality of the finished product of the color masterbat...

Embodiment 1

[0050] Dust removal: Weigh 80% of titanium dioxide, 1% of hindered amine light stabilizer, 0.5% of aluminum-titanium composite coupling agent, 0.5% of ultraviolet light absorber and 18% of low-density polyethylene, and compress the above raw materials The air is dedusted;

[0051] Mixing: Use a high-speed mixer to perform high-speed shear mixing on the dust-removed raw materials at a speed of 440rpm;

[0052] Extrusion molding: use the twin-screw extruder to melt and plasticize the mixed raw materials. The temperature of each heating section of the twin-screw extruder is: 125°C in the conveying section, 150°C in the melting section, 170°C in the mixing section, and 170°C in the exhaust section. 190°C, 195°C in the homogenization section and 190°C in the discharge section, the die head temperature of the twin-screw extruder is 190°C, and the raw materials are melted and plasticized to form a melt;

[0053] Cooling and cutting: After cooling the material strips, dry them. The d...

Embodiment 2

[0056] Dust removal: Weigh 70% of titanium dioxide, 0.3% of hindered amine light stabilizer, 1% of aluminum-titanium composite coupling agent, 0.1% of ultraviolet light absorber and 28.6% of low-density polyethylene, and compress the above raw materials The air is dedusted;

[0057] Mixing: Use a high-speed mixer to perform high-speed shear mixing on the dust-removed raw materials at a speed of 725rpm;

[0058] Extrusion molding: use the twin-screw extruder to melt and plasticize the mixed raw materials. The temperature of each heating section of the twin-screw extruder is: 120°C in the conveying section, 160°C in the melting section, 175°C in the mixing section, and 175°C in the exhaust section. 180°C, 200°C in the homogenization section and 195°C in the discharge section, the die head temperature of the twin-screw extruder is 200°C, and the raw materials are melted and plasticized to form a melt;

[0059] Cooling and cutting: After cooling the strips, they are dried, the dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com