Freeze-dried dextro-oxiracetam preparation for injection and preparation method thereof

A technology for freeze-dried preparations and injections, which is applied in the field of dexoxiracetam freeze-dried preparations for injection and its preparation, and can solve problems such as the lack of technical disclosure of dexoxiracetam freeze-dried preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

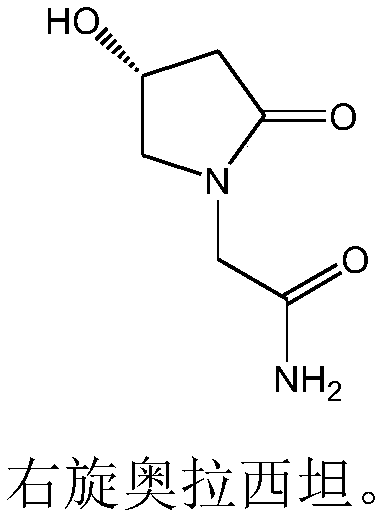

Image

Examples

Embodiment 1

[0022]Dissolve D-Oxiracetam in formic acid with a mass concentration of ≥ 85%, the weight ratio of formic acid and D-Oxiracetam is 5:1, keep stirring at a stirring speed of 300 r / min, and heat up to 90 °C for insulation 45min, add activated carbon to decolorize, filter, adjust the pH of the filtrate to 6.0 with an aqueous sodium hydroxide solution with a mass concentration of 20%, crystallize at 0 ~ 5 ℃, suction filtration, collect the filter residue, at 30 ℃, the relative humidity is 70% Dry under conditions for 4h. Test equipment conditions: use Bruker D2PHASER powder diffractometer for room temperature test, test conditions are: Cu Ka It is the light source, the voltage is 30kV, the current is 10mA, the test step is 0.014°, the scanning speed is 0.1s / step, and the scanning range is 5-40° (2θ). After testing, the D-Oxiracetam crystals prepared in Example 1 have diffraction angles 2θ of 10.54±0.2°, 13.76±0.2°, 14.14±0.2°, 16.64±0.2°, 17.76±0.2°, 18.72±0.2° , 20.16±0.2°, 21...

Embodiment 2

[0024] Dissolve D-Oxiracetam in formic acid with a mass concentration of ≥ 85%, the weight ratio of formic acid and D-Oxiracetam is 3:1, keep stirring at a stirring speed of 100 r / min, and heat up to 88 °C for insulation 55min, add activated carbon to decolorize, filter, adjust the pH of the filtrate to 5.8 with an aqueous sodium hydroxide solution with a mass concentration of 10%, crystallize at 0 ~ 5 ℃, suction filtration, collect the filter residue, at 20 ℃, the relative humidity is 60% Dry under conditions for 3h. Referring to the determination method of crystal form in Example 1, the results show that the crystal prepared in Example 2 is the same crystal form as that in Example 1.

Embodiment 3

[0026] Dissolve D-Oxiracetam in formic acid with a mass concentration of ≥ 85%, the weight ratio of formic acid and D-Oxiracetam is 6:1, keep stirring at a stirring speed of 400 r / min, and heat up to 100 °C for insulation 35min, add activated carbon to decolorize, filter, adjust the pH of the filtrate to 6.4 with an aqueous sodium hydroxide solution with a mass concentration of 30%, crystallize at 0 ~ 5 °C, suction filtration, collect the filter residue, at 40 °C, the relative humidity is 90%. Dry under conditions for 5h. Referring to the determination method of crystal form in Example 1, the results show that the crystal prepared in Example 2 is the same crystal form as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com