Carbonaceous reducing agent pellets for industrial silicon production and preparation method thereof

A reducing agent, industrial silicon technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problem of not finding an ideal carbonaceous reducing agent, and achieve resource utilization, excellent performance, and lower preparation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

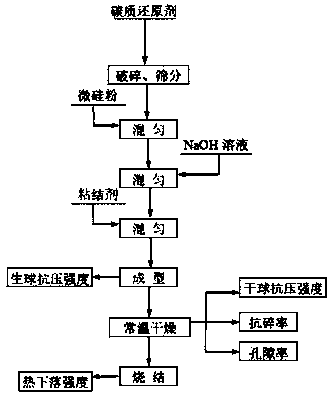

[0027] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

[0028] The composition of the carbonaceous reducing agent for industrial silicon production in this embodiment includes no more than 3% by mass of charcoal, and also includes 0-48.81% by mass of washed coal powder, 26.5%-70% by mass of petroleum coke powder, 8% to 10% mass ratio of additives and 3% to 5% mass ratio of binder, with sodium hydroxide solution as the wetting medium (the concentration of sodium hydroxide solution is 4mol / L, and the mass ratio added is 6% ), mixed evenly and pressed into agglomerates to make carbonaceous reducing agent. When the particle size range of the largest particle among the components of the carbonaceous reducing agent is 3.3mm-4.75mm, the proportion of the largest particle is 60%.

[0029] Further, starch A is selected as the binder, and its composition ratio is: 0.38% protein, 0.07% fat, 13% moisture, 0.17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com