Thermoplastic thermistor composite material with positive temperature coefficient and preparation method thereof

A positive temperature coefficient and composite material technology, which is applied to resistors with positive temperature coefficients, resistors, non-adjustable metal resistors, etc., can solve the problems of complex procedures, increased density, high resistivity, etc., and achieve simple manufacturing methods, Enhanced conductivity and less conductive filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

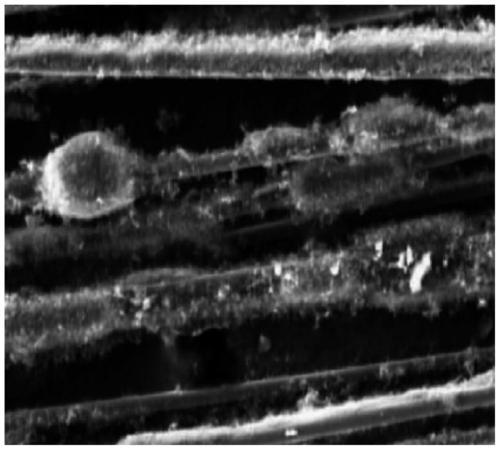

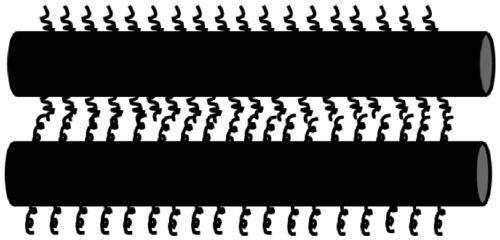

Image

Examples

Embodiment 1

[0048] A positive temperature coefficient thermoplastic thermistor composite material, by weight percentage, comprising the following components:

[0049]

[0050] A positive temperature coefficient thermoplastic thermistor composite material is prepared by the following steps:

[0051] (1) Mix the carbon fiber powder with carbon nanotubes grown on the surface and KH-550 evenly, and dry to obtain a mixture A; the drying temperature is 50° C., and the drying time is 60 minutes;

[0052] (2) The thermoplastic polymer material and the ultra-high molecular weight polyethylene are mechanically mixed with the mixture A at room temperature to obtain the mixture B;

[0053] (3) mix mixture B with antioxidant 1010, UV-P, and naphthenic oil at room temperature and extrude in a twin-screw extruder, cool, dry and granulate to obtain a thermoplastic thermistor composite material; The cooling temperature was 30°C.

Embodiment 2

[0055] A positive temperature coefficient thermoplastic thermistor composite material, by weight percentage, comprising the following components:

[0056]

[0057]

[0058] A positive temperature coefficient thermoplastic thermistor composite material is prepared by the following steps:

[0059] (1) Mix the carbon fiber powder with carbon nanotubes grown on the surface and KH560 evenly, and dry to obtain the mixture A; the drying temperature is 100° C., and the drying time is 10 minutes;

[0060] (2) The thermoplastic polymer material and the ultra-high molecular weight polyethylene are mechanically mixed with the mixture A at room temperature to obtain the mixture B;

[0061] (3) mix mixture B with antioxidant 168, UV-326, and naphthenic oil at room temperature and extrude in a twin-screw extruder, cool, dry and granulate to obtain a thermoplastic thermistor composite material; The cooling temperature was 5°C.

Embodiment 3

[0063] A positive temperature coefficient thermoplastic thermistor composite material, by weight percentage, comprising the following components:

[0064]

[0065] A positive temperature coefficient thermoplastic thermistor composite material is prepared by the following steps:

[0066] (1) Mix carbon fiber powder with carbon nanotubes grown on the surface and KH570 evenly, and dry to obtain mixture A; the drying temperature is 90° C., and the drying time is 50 minutes;

[0067] (2) The thermoplastic polymer material and the ultra-high molecular weight polyethylene are mechanically mixed with the mixture A at room temperature to obtain the mixture B;

[0068] (3) mix mixture B with antioxidant 264, UV-531, and naphthenic oil at room temperature and extrude in a twin-screw extruder, cool, dry and granulate to obtain a thermoplastic thermistor composite material; The cooling temperature was 20°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com