Early strength agent, preparation method thereof and cement paste for well cementation

A technology of early strength agent, alkali metal chloride, applied in chemical instruments and methods, drilling composition and other directions, can solve problems such as poor effect, achieve the effect of improving diffusion rate, promoting coagulation and hardening, and increasing ionic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

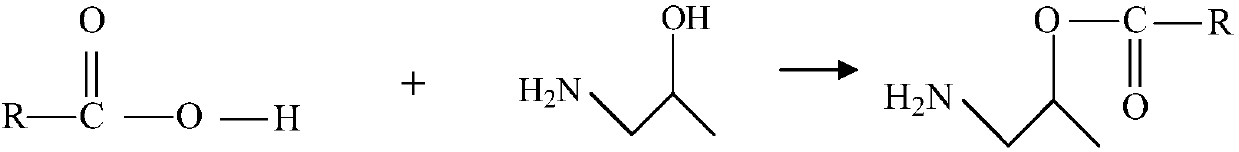

Method used

Image

Examples

preparation example Construction

[0061] In the second aspect, the embodiment of the present invention also provides a preparation method of any of the aforementioned early strength agents, and the preparation method includes:

[0062] According to the weight of each component, add alkali metal chloride and / or alkaline earth metal chloride, calcium nitrate, sodium nitrite, and carboxylic alcohol amine ester into water, stir to obtain an early strength agent;

[0063] The mass percentage of the mixture of alkali metal chloride and / or alkaline earth metal chloride, calcium nitrate, sodium nitrite, and carboxylic alcohol amine ester in the water is 30% to 60%.

[0064] The above preparation method is simple and can be prepared and used on site.

[0065] In the above method, the specific time of stirring is not limited, and the alkali metal chloride and / or alkaline earth metal chloride, calcium nitrate, sodium nitrite, and carboxylic alcohol amine ester can be uniformly dissolved in water.

[0066] As an example, the stirri...

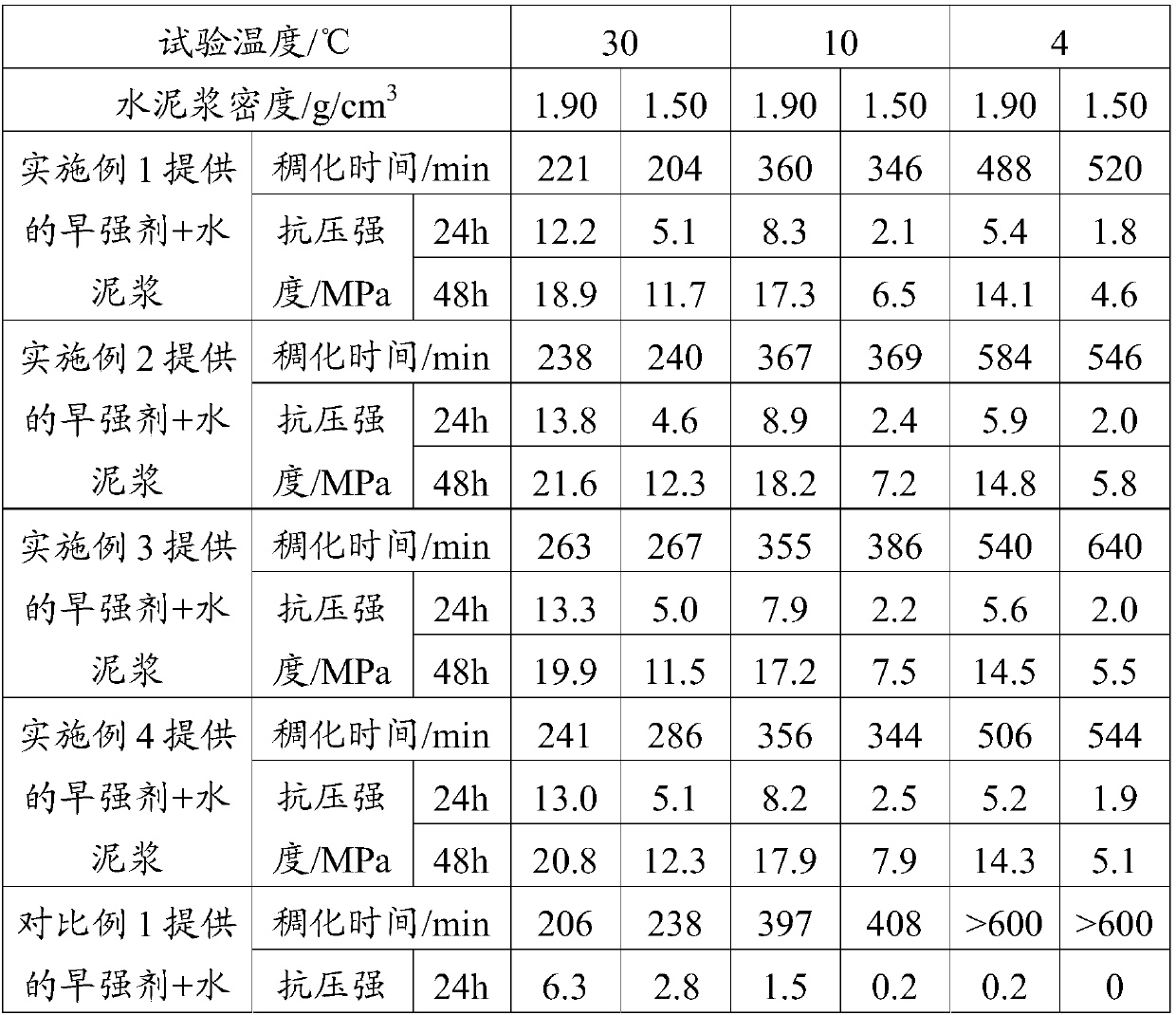

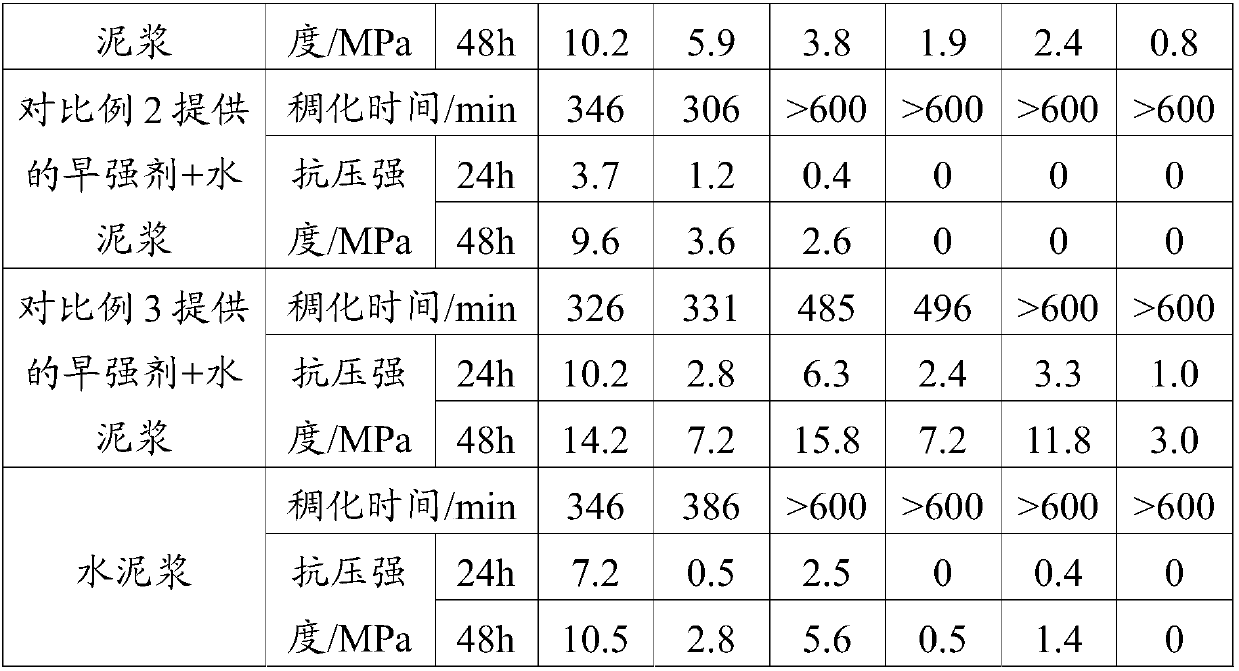

Embodiment 1

[0077] This embodiment provides an early-strength agent, which is prepared by the following method: 5g potassium chloride, 20g calcium nitrate, 20g sodium nitrite, 5g carboxylic alcohol amine ester are added to 50g water and stirred to obtain The early strength agent provided in this embodiment.

[0078] Among them, the carboxylic alcohol amine ester is obtained by adding 7.5 g of triisopropanolamine and 9.8 g of maleic anhydride into a three-necked flask, and stirring and polymerizing at 80°C.

Embodiment 2

[0080] This embodiment provides an early strength agent, which is prepared by the following method: 10g calcium chloride, 15g calcium nitrate, 25g sodium nitrite, 7g carboxylic alcohol amine ester are added to 85g water and stirred to obtain The early strength agent provided in this embodiment.

[0081] Among them, the carboxylic acid alcohol amine ester is obtained by adding 7.5 g of triisopropanolamine and 11.6 g of maleic acid into a three-necked flask, and stirring and polymerizing at 85°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com