Gas heat pump device based on heat source tower

A technology of gas heat pump and heat source tower, which is applied to machines using waste heat, heating methods, household heating, etc. It can solve problems such as inability to obtain air heat, waste of resources, and increased initial investment in equipment, so as to improve the utilization factor of primary energy, Avoid the problem of frosting and solve the effect of excess heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

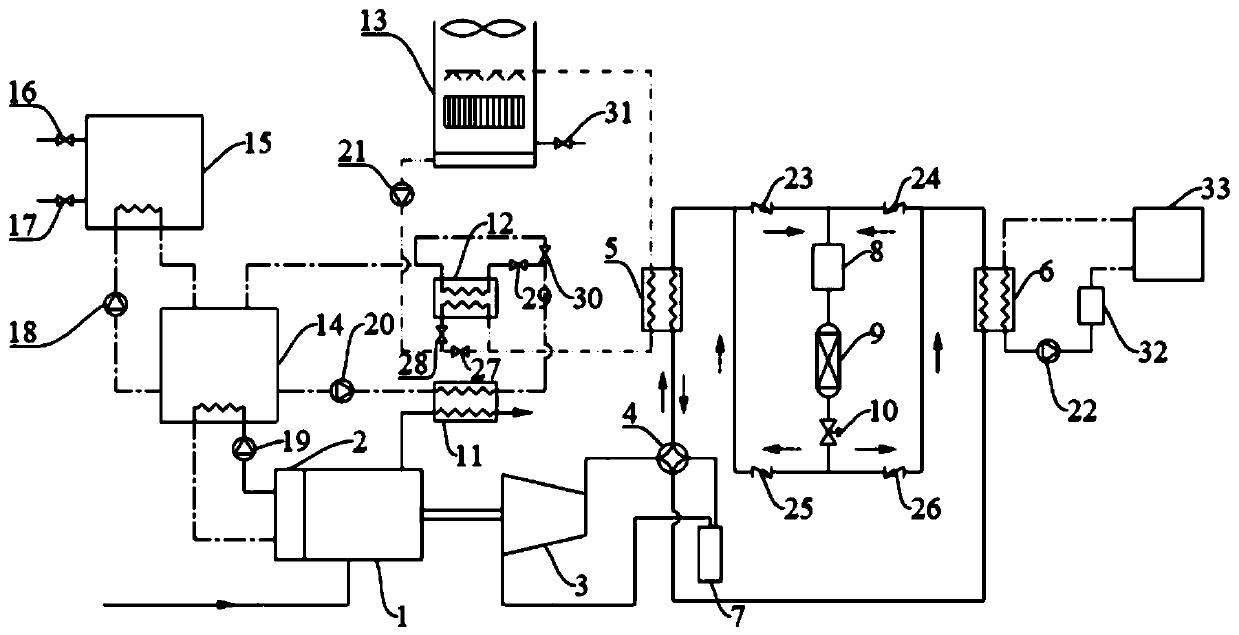

[0019] Structure, principle and mode of operation of the present invention are further elaborated below in conjunction with accompanying drawing:

[0020] Such as figure 1 As shown, a gas heat pump device based on a heat source tower mainly includes a solution circulation unit, a gas heat pump unit, a waste heat recovery unit and a user unit.

[0021] The gas heat pump unit includes gas engine 1, compressor 3, four-way reversing valve 4, solution-refrigerant heat exchanger 5, water-refrigerant heat exchanger 6, liquid receiver 8, dry filter 9, electronic expansion valve 10. Gas-liquid separator 7, first check valve 23, second check valve 24, third check valve 25 and fourth check valve 26, wherein the gas engine 1 and compressor 3 are connected through a coupling , the compressor 3 is connected to the gas-liquid separator 7 through the four-way reversing valve 4 to form a circuit, and the four-way reversing valve 4 is connected to the solution-refrigerant heat exchanger 5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com