Photocatalyst and preparation method and application thereof

A technology of photocatalyst and hydrothermal reaction, applied in the field of photocatalysis, to achieve the effects of improving catalytic activity, photocatalytic performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

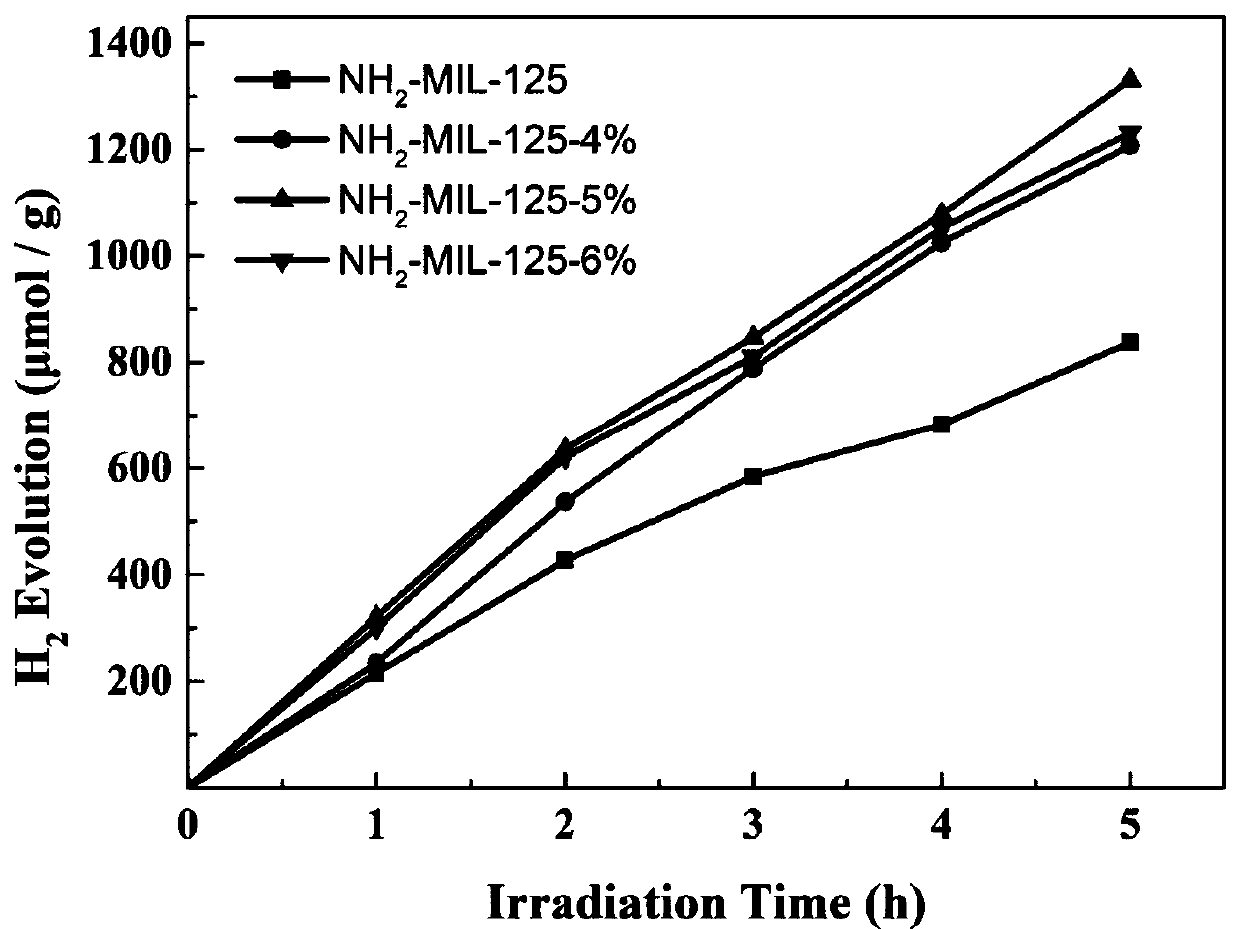

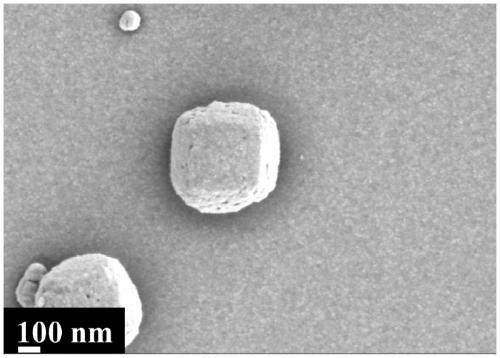

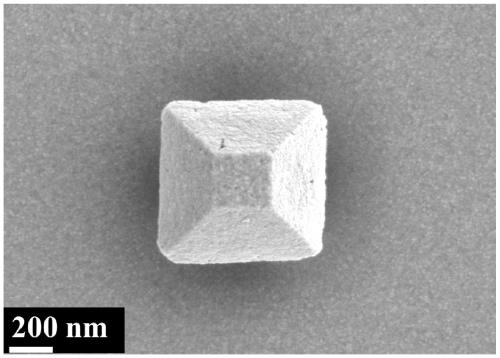

[0029] This embodiment provides a series of photocatalyst NH 2 - MIL-125, the preparation method of which is as follows.

[0030] Prepare 10mL N,N-dimethylformamide and methanol mixed solution (V N,N-二甲基甲酰胺 :V 甲醇 =9:1), adding the total moles of 2-aminoterephthalic acid and 3-aminoisobenzoic acid mixed ligand (the molar ratio of 3-aminoisobenzoic acid in the ligand is x), fully stirred and dissolved After that, 1 mmol tetrabutyl titanate was added, stirred at room temperature for 30 min, then transferred to a 50 mL polytetrafluoroethylene hydrothermal reactor, and reacted at 150° C. for 3 days. After the hydrothermal reaction is completed, the product is separated by suction filtration, washed three times with N,N-dimethylformamide and methanol, and the obtained product is dried in a blast oven at 120°C for 1 day to obtain the defective NH 2 -MIL-125-x photocatalyst, x is the molar ratio of 3-aminoisobenzoic acid in the ligand, specifically 0% (i.e. pure NH 2 -MIL-125), 4%...

Embodiment 2

[0032] This embodiment provides a photocatalyst NH 2 -MIL-125-5%, which is prepared as follows.

[0033] Prepare 10mL N,N-dimethylformamide and methanol mixed solution (V N,N-二甲基甲酰胺 :V 甲醇 =9:1), adding total moles of 2-aminoterephthalic acid and 3-aminoisobenzoic acid mixed ligand (the molar ratio of 3-aminoisobenzoic acid in the mixed ligand is 5%), fully After stirring and dissolving, 1 mmol of tetraethyl titanate was added, stirred at room temperature for 30 min, then transferred to a 50 mL polytetrafluoroethylene hydrothermal reaction kettle, and reacted at 180° C. for 16 h. After the hydrothermal reaction is completed, the product is separated by suction filtration, washed three times with N,N-dimethylformamide and methanol, and the obtained product is dried in a blast oven at 120°C for 1 day to obtain the defective NH 2 - MIL-125-5% photocatalyst.

Embodiment 3

[0035] This embodiment provides a photocatalyst NH 2 -MIL-125-5%, which is prepared as follows.

[0036] Prepare 10mL N,N-dimethylformamide and methanol mixed solution (V N,N-二甲基甲酰胺 :V 甲醇 =9:1), adding a total molar number of 2-aminoterephthalic acid and 3-aminoisobenzoic acid mixed ligand (the molar ratio of 3-aminoisobenzoic acid in the mixed ligand is 5%), fully After stirring and dissolving, 1 mmol tetraisopropyl titanate was added, stirred at room temperature for 30 min, then transferred to a 50 ml polytetrafluoroethylene hydrothermal reaction kettle, and reacted at 100°C for three days. After the hydrothermal reaction is completed, the product is separated by suction filtration, washed three times with N,N-dimethylformamide and methanol, and the obtained product is dried in a blast oven at 120°C for 1 day to obtain the defective NH 2 - MIL-125-5% photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com