Room-temperature preparation method of iron carbon particles as well as application of iron carbon particles

An iron-carbon and particle technology, which is applied to the field of room temperature preparation of iron-carbon particles, can solve the problems of the destruction of the structure and performance of the hydrothermal biomass carbon, and the difficulty in using the hydrothermal biomass carbon, so as to reduce the preparation cost, save the energy consumption, The effect of strong activation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

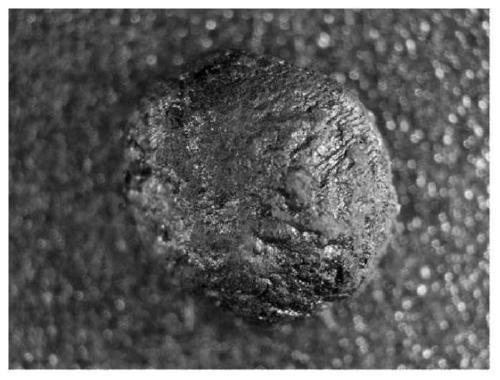

[0022] Using iron filings, rice husks and sodium alginate as raw materials to prepare coated iron-carbon particles comprises the following steps:

[0023] (1) After crushing and sieving the rice husk to make the particle size ≤ 1mm, put it into the reaction kettle and heat it at 180°C for 6h, and the heating rate is 1°C / min;

[0024] (2) Fully mix iron filings, 2 / 3 biochar and 1 / 6 sodium alginate in 100ml deionized water with a mass ratio of 1 / 6;

[0025] (3) Add the mixture dropwise to 1% (w / v) CaCl via syringe 2 In, the drop rate is 1mL / min;

[0026] (4) After forming spherical iron-carbon particles, soak the iron-carbon particles in the crosslinking agent for 4h;

[0027] (5) The iron-carbon particles soaked in (4) were washed with deionized water, and vacuum-dried at 40° C. for 24 hours to finally obtain iron-carbon particle materials.

Embodiment 2

[0029] Using iron filings, rice husks and sodium alginate as raw materials to prepare coated iron-carbon particles comprises the following steps:

[0030] (1) After crushing and sieving the rice husk to make the particle size ≤ 1mm, put it into the reaction kettle and heat it at 200°C for 8h, and the heating rate is 5°C / min;

[0031] (2) Fully mix iron filings, 1 / 3 biochar and 1 / 3 sodium alginate in 100ml deionized water with a mass ratio of 1 / 3;

[0032] (3) Add the mixture dropwise to 2% (w / v) CaCl via syringe 2 In, the drop rate is 5mL / min;

[0033] (4) After forming spherical iron-carbon particles, soak the iron-carbon particles in the crosslinking agent for 10h;

[0034] (5) The iron-carbon particles soaked in (4) were washed with deionized water, and vacuum-dried at 50° C. for 48 hours to finally obtain iron-carbon particle materials.

Embodiment 3

[0036] Using iron filings, rice husks and sodium alginate as raw materials to prepare coated iron-carbon particles comprises the following steps:

[0037] (1) After crushing and sieving the rice husk to make the particle size ≤ 1mm, put it into the reaction kettle and heat it at 220°C for 10h, and the heating rate is 10°C / min;

[0038] (2) Fully mix iron filings, 1 / 6 biochar and 1 / 6 sodium alginate in 100ml deionized water with a mass ratio of 2 / 3;

[0039] (3) Add the mixture dropwise to 2.5% (w / v) CaCl via syringe 2 In, the drop rate is 7mL / min;

[0040] (4) After forming spherical iron-carbon particles, soak the iron-carbon particles in the crosslinking agent for 12h;

[0041] (5) The iron-carbon particles soaked in (4) were washed with deionized water, and vacuum-dried at 60° C. for 60 hours to finally obtain iron-carbon particle materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com