Preparation method and equipment of environment-friendly rubber reinforcing agent

A kind of rubber reinforcing agent and environmental protection technology, applied in the field of rubber additives, can solve the problems of complex preparation process, low yield of white carbon black, increased sludge treatment cost, etc., and achieve the effect of simple and easy process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

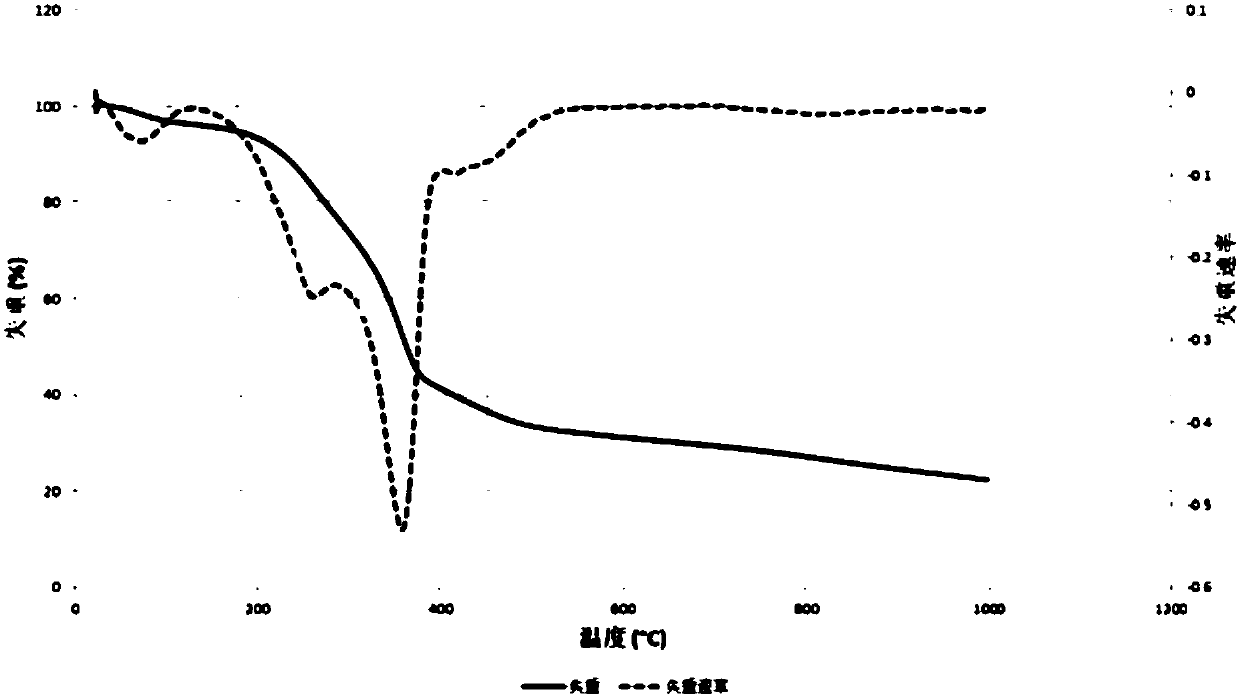

[0044] A preparation method of an environment-friendly rubber reinforcing agent, comprising the following steps:

[0045] (1) Inactivate the untreated primary sludge in a high-temperature pressure cooker at 120°C for 10 minutes, then dry it at 55°C to constant weight, and dry the dried sludge in a nitrogen atmosphere with a flow rate of 500mL / min , heat up to 550°C at a rate of 10°C / min, and then keep it warm for pyrolysis. The hold time is 90min, and a black carbonaceous solid is obtained;

[0046] (2) The black carbonaceous solid is subjected to wet TEMA grinding in a vibrating disc grinder. The solid-to-liquid ratio of wet TEMA grinding is 1:0.8, and the grinding time is 1 min. After the grinding is completed, put the ground product into an oven Dry at 105°C to constant weight to obtain the environment-friendly rubber reinforcing agent.

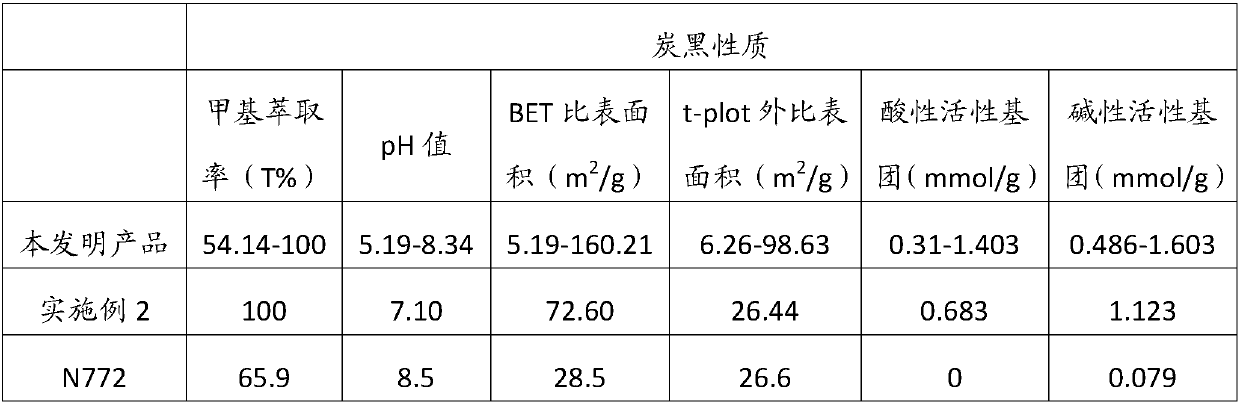

Embodiment 2

[0048] A preparation method of an environment-friendly rubber reinforcing agent, comprising the following steps:

[0049] (1) Inactivate the untreated secondary sludge in a high-temperature pressure cooker at a temperature of 125°C for 15 minutes, and then dry it at 60°C to constant weight. Under the atmosphere, the temperature was raised to 600°C at a rate of 10°C / min, and then kept for pyrolysis. The holding time was 90 minutes, and a black carbonaceous solid was obtained;

[0050] (2) The black carbonaceous solid is subjected to wet TEMA grinding in a vibrating disc grinder, the solid-to-liquid ratio of wet TEMA grinding is 1:1, and the grinding time is 1.5min. After the grinding is completed, the grinding product is placed in Dry in an oven at 105°C to constant weight to obtain the environment-friendly rubber reinforcing agent.

Embodiment 3

[0052] A preparation method of an environment-friendly rubber reinforcing agent, comprising the following steps:

[0053] (1) Inactivate the untreated primary sludge in a high-temperature pressure cooker at a temperature of 123°C for 12 minutes, then dry it to a constant weight at 62°C, and dry the dried sludge in a flow rate of 570mL / min Under a nitrogen atmosphere, the temperature was raised to 620°C at a rate of 11°C / min, and then kept for pyrolysis. The holding time was 110 minutes, and a black carbonaceous solid was obtained;

[0054] (2) The black carbonaceous solid is subjected to wet TEMA grinding in a vibrating disc grinder. The solid-to-liquid ratio of wet TEMA grinding is 1:0.9, and the grinding time is 2 minutes. After the grinding is completed, put the ground product into an oven Dry at 105°C to constant weight to obtain the environment-friendly rubber reinforcing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com