Formula, preparation method and application technology of high-tension deep-drawn luncheon meat can inner wall coating

A technology for canned luncheon meat and coatings, applied in fire-retardant coatings, antifouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve the problem of brittle paint film, poor tensile resistance of the paint film, and loss of film release performance and other problems, to achieve the effects of excellent high temperature sterilization resistance, easy operation and construction, and good tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

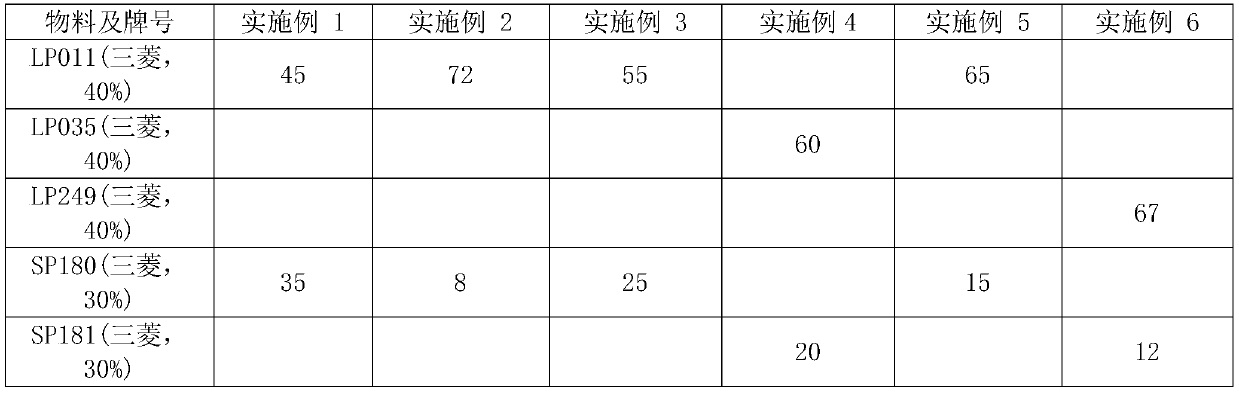

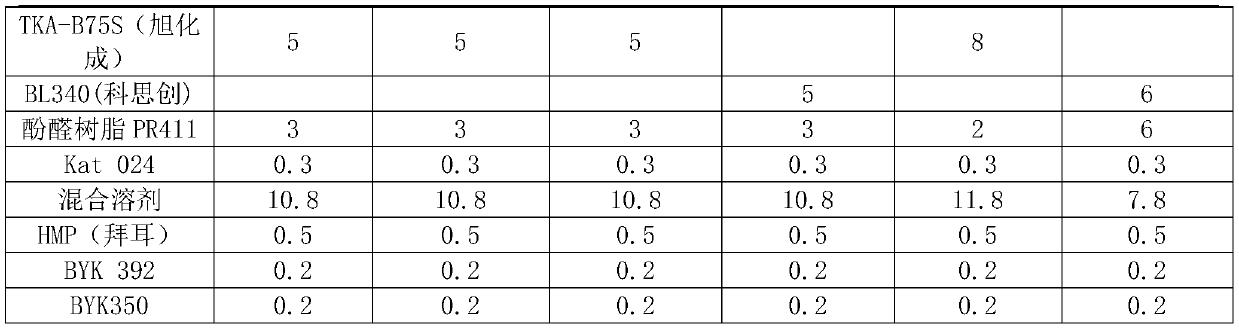

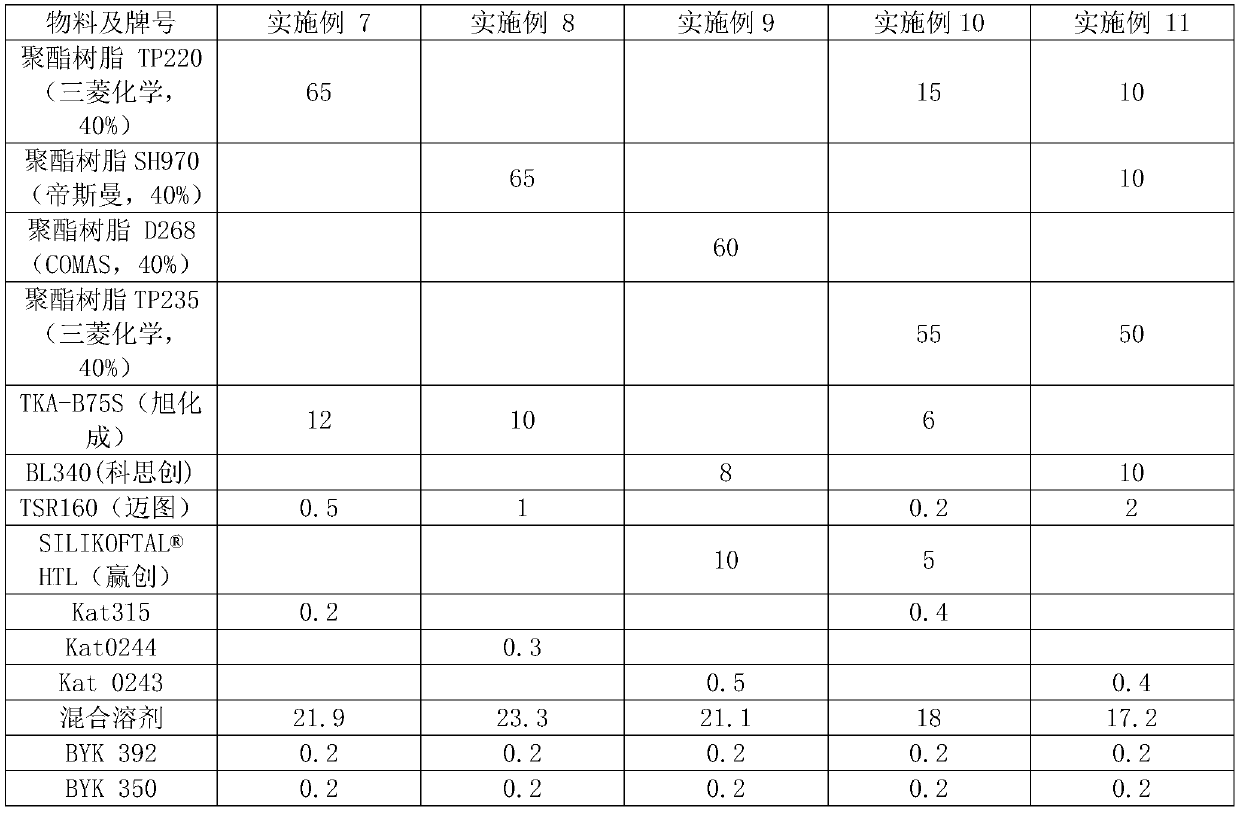

[0040]Specific embodiments of the present invention will be further described below. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

[0041] The invention discloses a high-stretch deep-drawn lunch meat can inner wall coating formulation, which includes a transparent base coat and a transparent top coat for making luncheon meat can plates, wherein the transparent base coat includes the following components counted by mass percentage Component composition:

[0042] Amorphous high molecular weight polyester resin: 40-70%;

[0043] Crystalline high molecular weight copolyester resin: 10-30%;

[0044] Blocked isocyanate: 3-10%;

[0045] Phenolic resin c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com