Banana essence, and preparation method thereof

A banana essence and banana technology, which is applied in the directions of essential oils/flavors, fat production, food forming, etc., can solve the problems of banana product flavor quality decline, not being liked by consumers, and unreal flavor, etc., and achieve good sales market, The appearance is clear and transparent, the effect of tiny particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

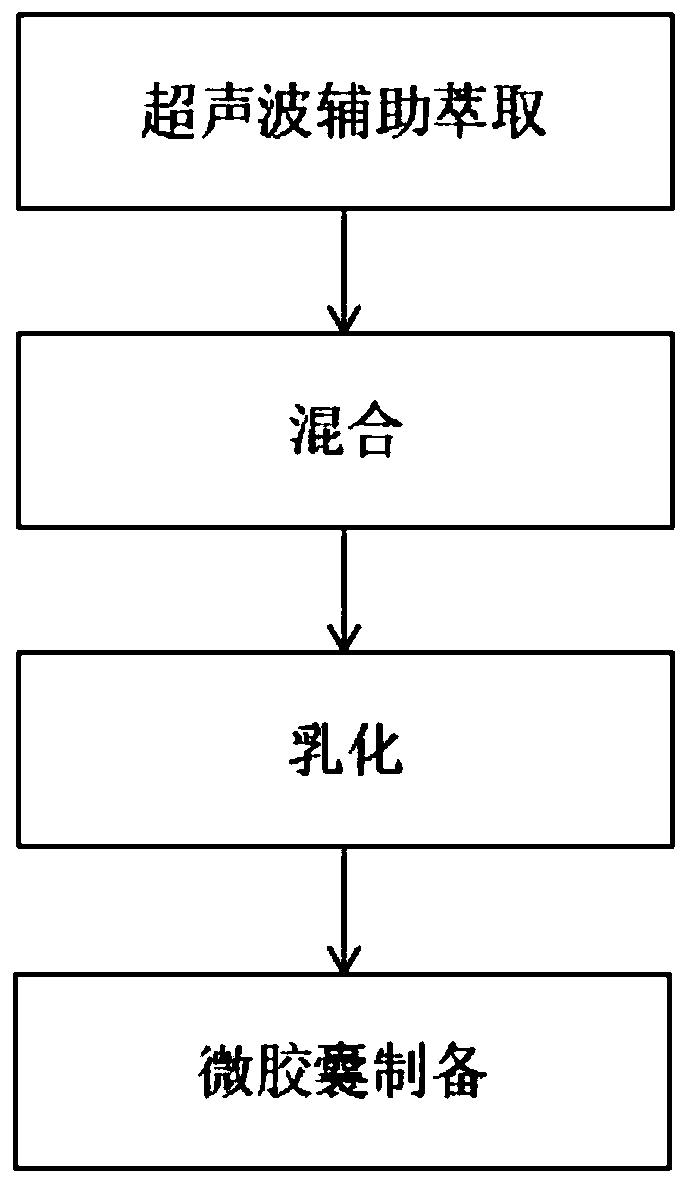

Method used

Image

Examples

Embodiment 1

[0032] Composition of raw materials (parts by weight): 88 parts of banana extract, 0.2 part of clove oil, 0.1 part of lemon oil, 0.02 part of sweet orange oil, 0.3 part of ethyl acetate, 1.8 parts of butyl butyrate, 1.5 parts of isoamyl butyrate, 0.6 part of butyl formate, 0.3 part of myrcene, 0.02 part of terpinene, 0.01 part of vanillin, 0.01 part of cis-3-hexenol, 0.02 part of styringyl acetate, 1 part of propylene glycol and 1 part of ethanol.

[0033] A preparation method of banana essence is characterized in that, it is prepared by the following method:

[0034] S1. Take by weighing 1kg of pulverized fresh banana peels and put them into a closed reactor, add 2kg of solvent, the solvent is a mixture of ethyl acetate, propylene glycol, ethanol and butyl acetate, and the volume ratio is 5:3:1:2 , put it into an ultrasonic generator, carry out ultrasonic-assisted extraction, the ultrasonic power is 800W, the extraction time is 30min, and concentrate to obtain the banana extr...

Embodiment 2

[0039]Composition of raw materials (parts by weight): 92 parts of banana extract, 0.5 part of clove oil, 0.3 part of lemon oil, 0.05 part of sweet orange oil, 0.8 part of ethyl acetate, 2.3 parts of butyl butyrate, 2.2 parts of isoamyl butyrate, 1.5 parts of butyl formate, 0.9 parts of myrcene, 0.05 parts of terpinene, 0.04 parts of vanillin, 0.04 parts of cis-3-hexenol, 0.05 parts of styryl acetate, 2 parts of propylene glycol and 2 parts of ethanol.

[0040] A preparation method of banana essence is characterized in that, it is prepared by the following method:

[0041] S1. Take by weighing 1kg of pulverized fresh banana peels and put them into a closed reactor, add 2kg of solvent, the solvent is a mixture of ethyl acetate, propylene glycol, ethanol and butyl acetate, and the volume ratio is 5:3:1:2 , put it into an ultrasonic generator, carry out ultrasonic-assisted extraction, the ultrasonic power is 1000W, the extraction time is 50min, and concentrate to obtain the banana...

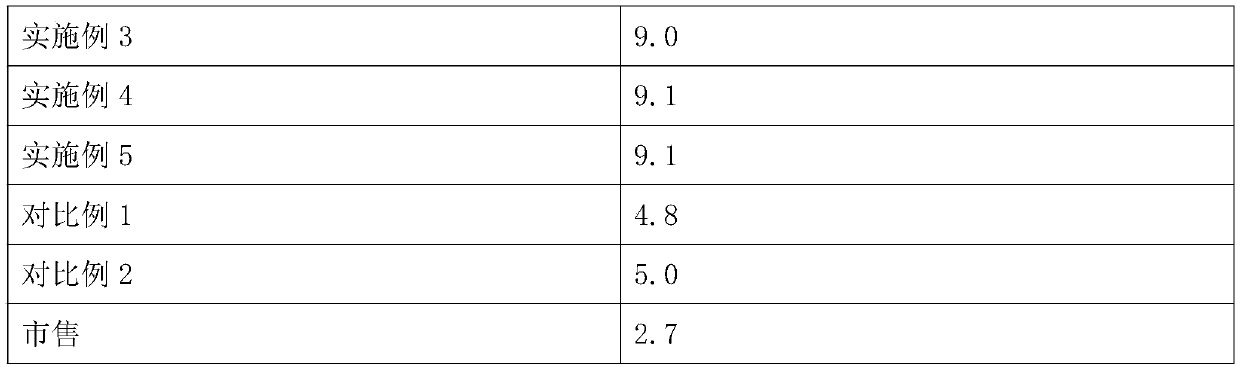

Embodiment 3

[0046] Composition of raw materials (parts by weight): 89 parts of banana extract, 0.3 part of clove oil, 0.15 part of lemon oil, 0.024 part of sweet orange oil, 0.4 part of ethyl acetate, 1.9 parts of butyl butyrate, 1.7 parts of isoamyl butyrate, 0.8 parts of butyl formate, 0.5 parts of myrcene, 0.03 parts of terpinene, 0.02 parts of vanillin, 0.01 parts of cis-3-hexenol, 0.02 parts of styringyl acetate, 1.2 parts of propylene glycol and 1.3 parts of ethanol.

[0047] A preparation method of banana essence is characterized in that, it is prepared by the following method:

[0048] S1. Take by weighing 1kg of pulverized fresh banana peels and put them into a closed reactor, add 2kg of solvent, the solvent is a mixture of ethyl acetate, propylene glycol, ethanol and butyl acetate, and the volume ratio is 5:3:1:2 , put it into an ultrasonic generator, carry out ultrasonic-assisted extraction, the ultrasonic power is 850W, the extraction time is 35min, and concentrate to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com