Regulation and control method based on energy valley polarization characteristic of two-dimensional transition metal chalcogenide

A technology of transition metal chalcogenide and polarization characteristics, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of not being able to give full play to the excellent performance of two-dimensional material atomic-level thickness and flexibility , to achieve the effect of low cost, good controllability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

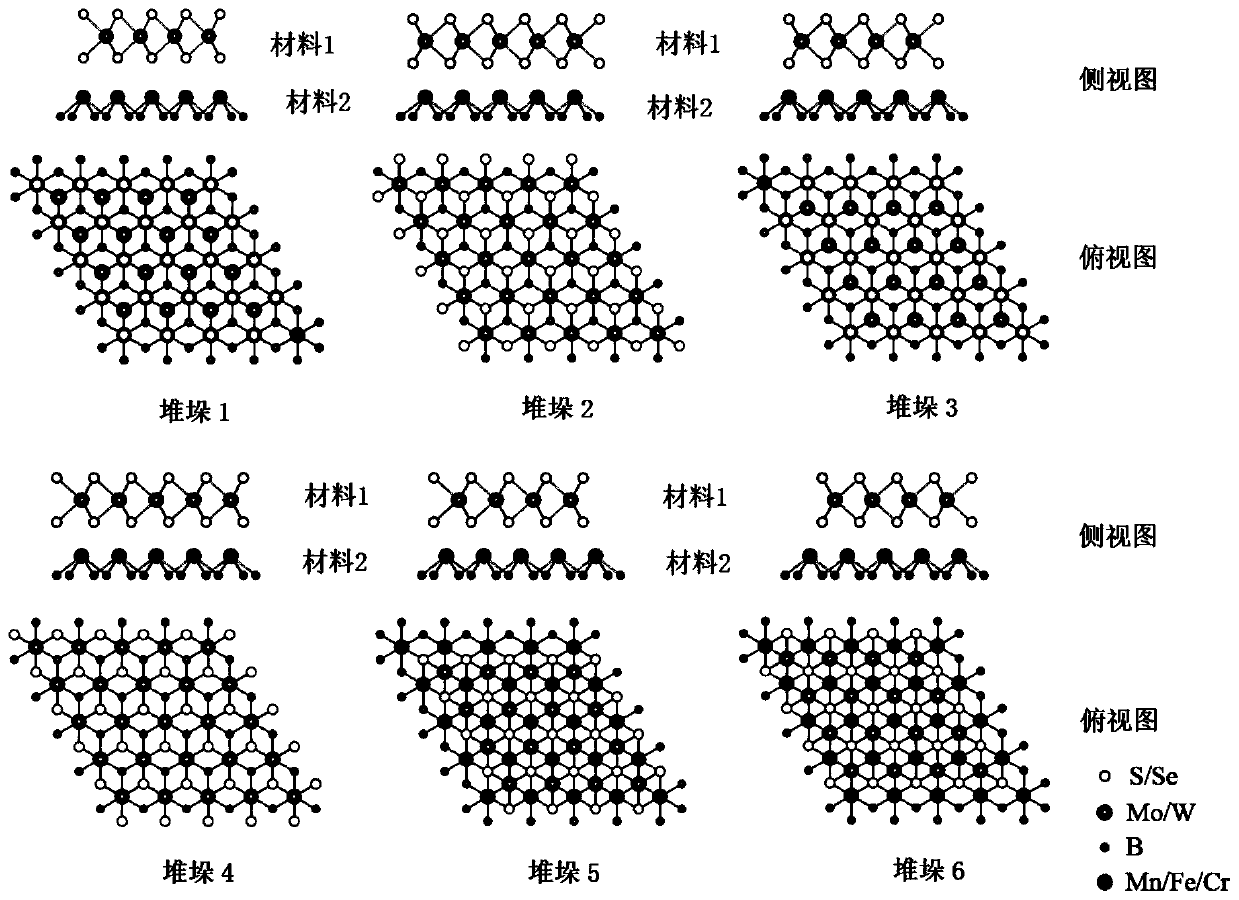

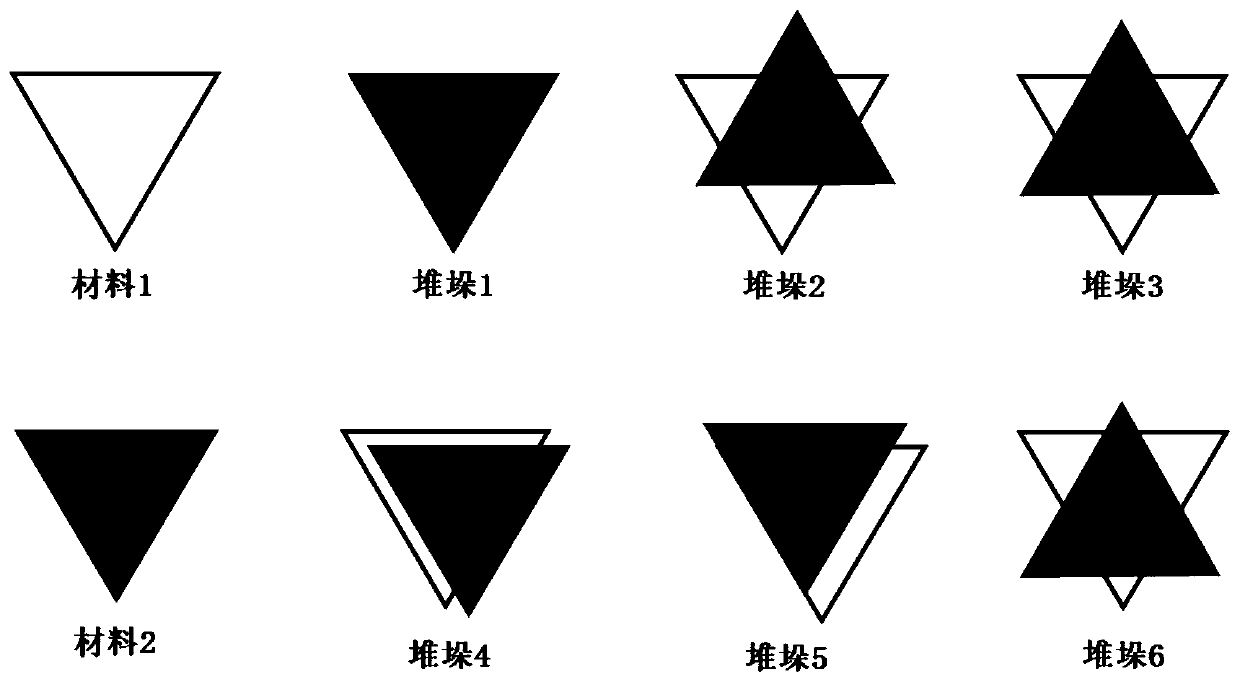

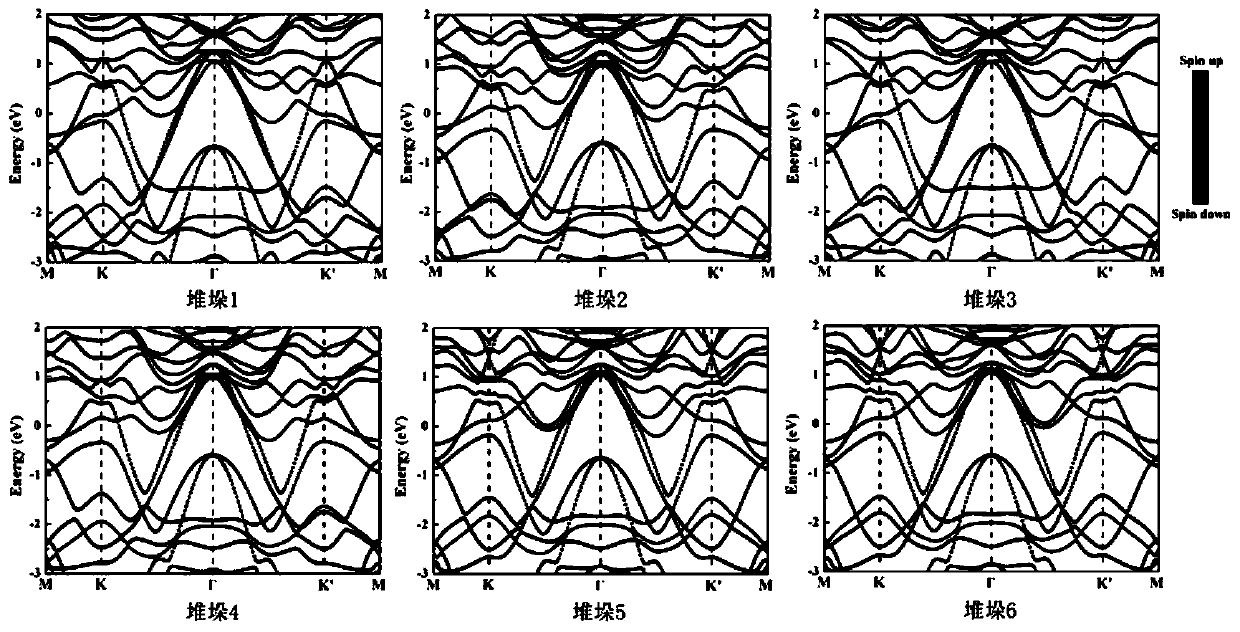

[0034] A method for regulating the energy valley polarization characteristics of two-dimensional transition metal chalcogenides, comprising the following steps:

[0035] (1) First prepare MnB 2 -WS 2 Monolayer WS in heterostructures 2 Material:

[0036] Evacuate the tube furnace reaction chamber to 10 -2 Torr, purged with 200 sccm argon to return to normal pressure.

[0037] Prepare two pieces of SiO 2 / Si substrates A and B, two SiO 2 Rinse the / Si substrate with a large amount of deionized water, put it in acetone solution and ultrasonically clean it for 8 minutes, take out the substrate, put it in absolute ethanol solution for ultrasonic cleaning for 8 minutes, take out the substrate again, put it into deionized water for ultrasonic cleaning for 8 minutes, and put the cleaned The substrate was blown dry with inert gas nitrogen.

[0038] SiO 2 / Si substrate A is placed on the carrier in the chamber of the thermal evaporation coating instrument, the tungsten trioxide po...

Embodiment 2

[0049] A method for regulating the energy valley polarization characteristics of two-dimensional transition metal chalcogenides, comprising the following steps:

[0050] (1) First prepare FeB 2 -WS 2 WS in heterostructures 2 Single layer material:

[0051] Evacuate the tube furnace reaction chamber to 10 -2 Torr, purged with 200 sccm argon to return to normal pressure.

[0052] Prepare two pieces of SiO 2 / Si substrates A and B, two SiO 2 Rinse the / Si substrate with a large amount of deionized water, put it in acetone solution and ultrasonically clean it for 8 minutes, take out the substrate, put it in absolute ethanol solution for ultrasonic cleaning for 8 minutes, take out the substrate again, put it into deionized water for ultrasonic cleaning for 8 minutes, and put the cleaned The substrate was blown dry with inert gas nitrogen.

[0053] SiO 2 / Si substrate A is placed on the carrier in the chamber of the thermal evaporation coating instrument, the tungsten trioxi...

Embodiment 3

[0062] A method for regulating the energy valley polarization characteristics of two-dimensional transition metal chalcogenides, comprising the following steps:

[0063] (1) First prepare CrB 2 -WS 2 WS in heterostructures 2 Single layer material:

[0064] Evacuate the tube furnace reaction chamber to 10 -2 Torr, purged with 200 sccm argon to return to normal pressure.

[0065] Prepare two pieces of SiO 2 / Si substrates A and B, two SiO 2 Rinse the / Si substrate with a large amount of deionized water, put it in acetone solution and ultrasonically clean it for 8 minutes, take out the substrate, put it in absolute ethanol solution for ultrasonic cleaning for 8 minutes, take out the substrate again, put it into deionized water for ultrasonic cleaning for 8 minutes, and put the cleaned The substrate was blown dry with inert gas nitrogen.

[0066] SiO 2 / Si substrate A is placed on the carrier in the chamber of the thermal evaporation coating instrument, the tungsten trioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com