Preparation method of alkali metal tungsten bronze powder

A technology of alkali metal tungsten bronze and alkali metal source, applied in chemical instruments and methods, tungsten compounds, nanotechnology for materials and surface science, etc., can solve the problems of long process and unclear principle, and achieve simple process , The effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Add 245.6972g of cesium carbonate, 953.4153g of tungstic acid, 162.7619g of tungsten dioxide, 340g of vitamin C and 5.3kg of deionized water into a 10L Hastelloy reactor. After sealing, turn on mechanical stirring. The speed of the stirrer is 300rpm. After pre-stirring, it was raised from room temperature to 300°C and kept for 10h. After cooling to below 100°C, the pressure in the reactor is released, and the material is discharged after further cooling. After washing, collecting and drying, carbon-coated cesium-tungsten bronze composite nanopowder is obtained. The concentration of the product formed in this system is about 20%, and the mass of the coated carbon layer is 10% of the mass of cesium tungsten bronze. 50 ml of the cooled material was taken out, and after centrifugation, the content of metal ions in the supernatant was analyzed by inductively coupled plasma mass spectrometry.

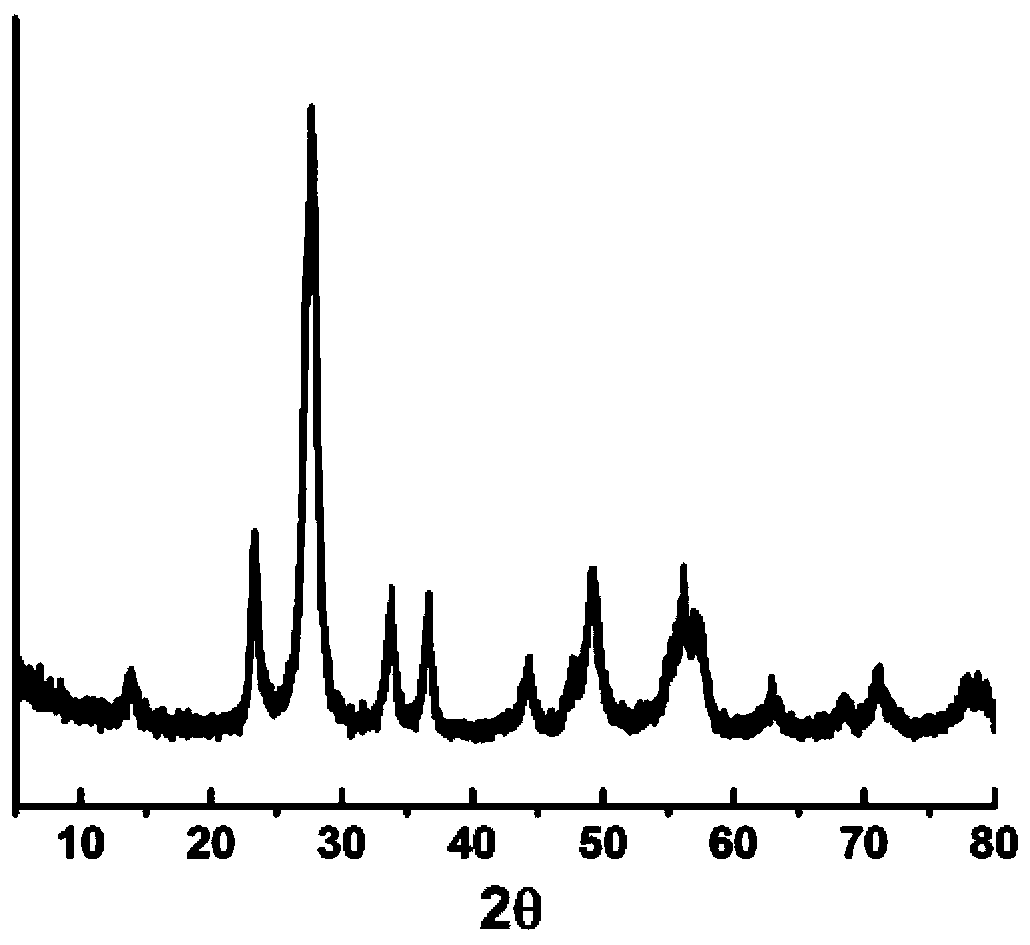

[0056] figure 1 is the powder X-ray diffraction (XRD) pattern of the prepared po...

Embodiment 2

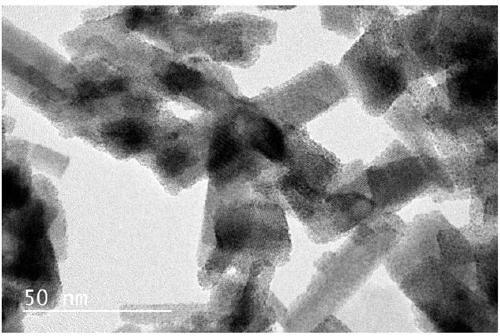

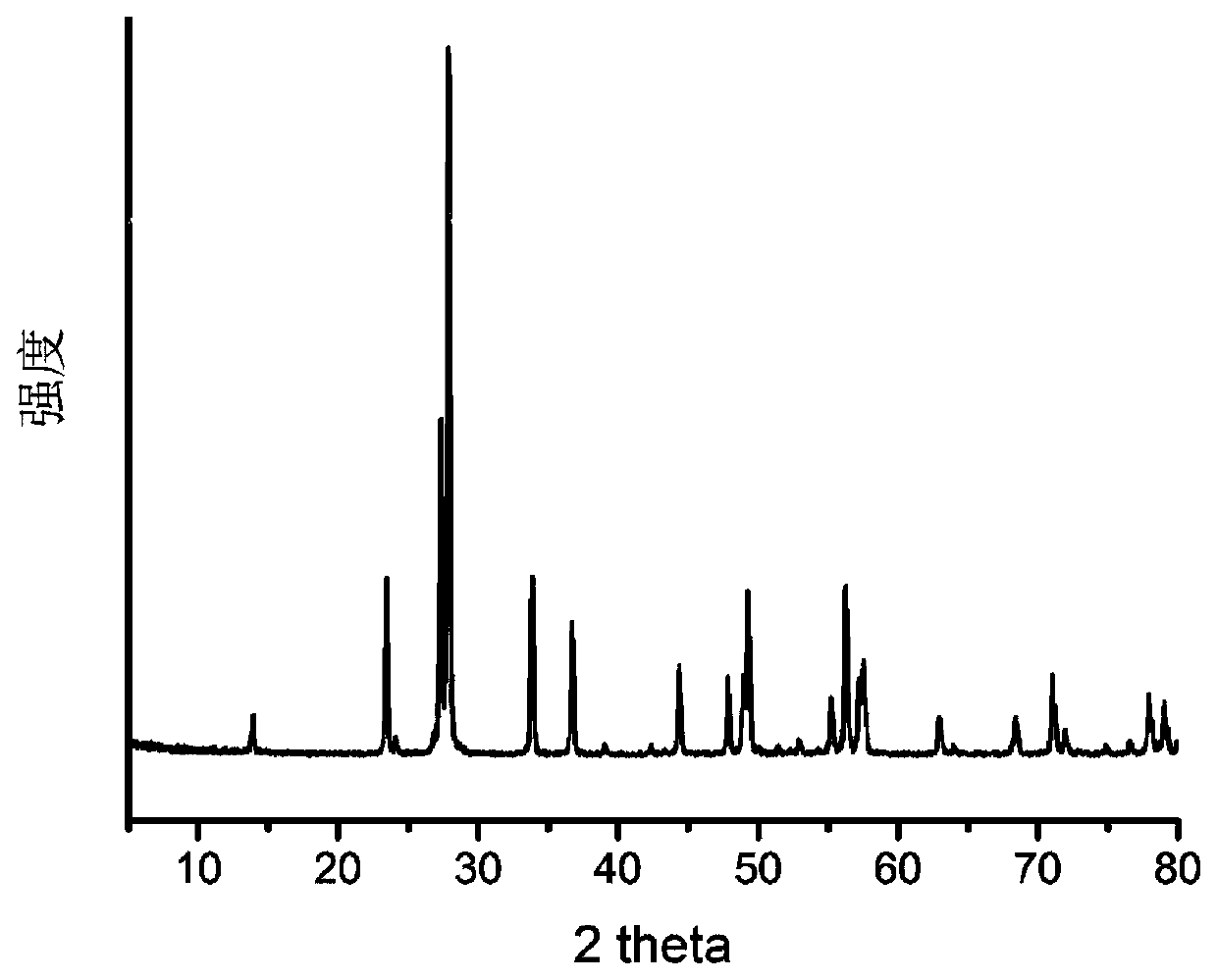

[0058] Add 245.6972g of cesium carbonate, 953.4153g of tungstic acid, 162.7619g of tungsten dioxide, 120g of glucose and 5.5kg of deionized water into a 10L Hastelloy reactor. After sealing, start the mechanical stirring. After stirring, it was raised from room temperature to 300°C and kept for 10h. After cooling to below 100°C, the pressure in the reactor is released, and the material is discharged after further cooling. After washing, collecting and drying, carbon-coated cesium-tungsten bronze composite nanopowder is obtained. The phase was detected as hexagonal Cs by XRD 0.32 WO 3 Cesium tungsten bronze phase, no other impurity phases were detected. An obvious coating structure can be seen by TEM detection, the obtained product is a nano flake with a width of about 10nm and a length of less than 50nm, and the thickness of the carbon coating layer is about 3nm. The concentration of the product formed in this system is about 20%, and the mass of the coated carbon layer is ...

Embodiment 3

[0060] Add 245.6972g of cesium carbonate, 953.4153g of tungstic acid, 162.7619g of tungsten dioxide, 340g of vitamin C, 120g of glucose and 5.5kg of deionized water into the 10L Hastelloy reactor. After sealing, start the mechanical stirring, and the speed of the mixer is 300rpm. After 30 minutes of pre-stirring, it was raised from room temperature to 300°C and kept for 10 hours. After cooling to below 100°C, the pressure in the reactor is released, and the material is discharged after further cooling. After washing, collecting and drying, carbon-coated cesium-tungsten bronze composite nanopowder is obtained. The phase was detected as hexagonal Cs by XRD 0.32 WO 3 Cesium tungsten bronze phase, no other impurity phases were detected. The obvious coating structure can be seen by TEM detection. The obtained product is a nano-flake with a width of about 10nm and a length of less than 50nm. The thickness of the carbon coating layer is about 10nm. The concentration of the product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com