Two-dimensional Zn doping Ca2So nano membrane and chemical gaseous phase precipitation method thereof

A chemical vapor deposition and nano-film technology, which is applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of poor crystallinity, low yield, and small grain size of two-dimensional nano-films, and achieve Good industrialization prospect, simple preparation process and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

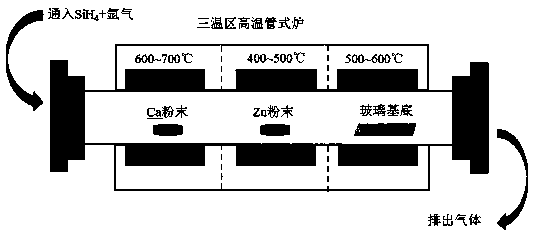

[0023] Preparation of two-dimensional Zn-doped Ca by chemical vapor deposition 2 The method for Si nano film, concrete steps are as follows:

[0024] (1) Put the glass substrate into acetone, absolute ethanol, and deionized water for 15 minutes and ultrasonically clean it for 15 minutes to remove impurities on the surface of the substrate;

[0025] (2) get the Ca powder and the Zn powder that the molar ratio is 40:0.5, will be housed 3.5 gram purity be the quartz vessel of the Ca powder of 99.9% be placed on the front end area of three temperature zones high-temperature tube furnace, will be equipped with 0.1 gram The quartz dish of Zn powder with a purity of 99.9% is placed in the middle area of the three-temperature zone high-temperature tube furnace, and the pretreated glass substrate is placed in the end zone of the three-temperature zone high-temperature tube furnace;

[0026] (3) Evacuate the vacuum degree of the high-temperature tube furnace to below 10 Pa, then cl...

Embodiment 2

[0029] Preparation of two-dimensional Zn-doped Ca by chemical vapor deposition 2 The method for Si nano film, concrete steps are as follows:

[0030] (1) Put the glass substrate into acetone, absolute ethanol, and deionized water for 15 minutes and ultrasonically clean it for 15 minutes to remove impurities on the surface of the substrate;

[0031] (2) get Ca powder and Zn powder that mol ratio is 40:3, will be equipped with 3.5 grams of purity and be the quartz dish of the Ca powder of 99.9% to be placed on the front end area of three temperature zones high-temperature tube furnace, will be equipped with 0.5 grams The quartz dish of Zn powder with a purity of 99.9% is placed in the middle area of the three-temperature zone high-temperature tube furnace, and the pretreated glass substrate is placed in the end zone of the three-temperature zone high-temperature tube furnace;

[0032] (3) Evacuate the vacuum of the high-temperature tube furnace to below 10 Pa, then close th...

Embodiment 3

[0035] Preparation of two-dimensional Zn-doped Ca by chemical vapor deposition 2 The method for Si nano film, concrete steps are as follows:

[0036] (1) Put the glass substrate into acetone, absolute ethanol, and deionized water for 15 minutes and ultrasonically clean it for 15 minutes to remove impurities on the surface of the substrate;

[0037] (2) get Ca powder and Zn powder that mol ratio is 40:2.5, the quartz dish that 2.3 grams of purity is the Ca powder of 99.9% is placed on the front end area of three temperature zone high-temperature tube furnaces, will be equipped with 0.3 grams of purity is The 99.9% Zn powder quartz vessel is placed in the middle area of the three-temperature zone high-temperature tube furnace, and the pretreated glass substrate is placed in the end area of the three-temperature zone high-temperature tube furnace;

[0038] (3) Evacuate the vacuum degree of the high-temperature tube furnace to below 10 Pa, then close the vacuum valve, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com