Preparation method of in-situ synthesis low-pressure cold spraying CuNiCoFeCrAl2.8 high-entropy alloy coating

A high-entropy alloy and in-situ synthesis technology, which is applied in the coating process of metal materials, coating, heating inorganic powder coating, etc., can solve the problems of affecting the quality and service life of the coating, and the decline of the mechanical properties of the coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In-situ synthesis of low pressure cold spray CuNiCoFeCrAl in this example 2.8 A method for preparing a high-entropy alloy coating, the method comprising:

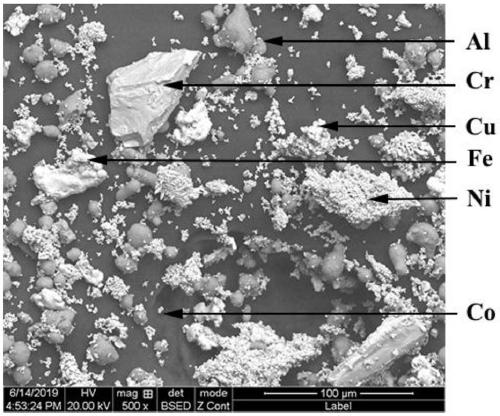

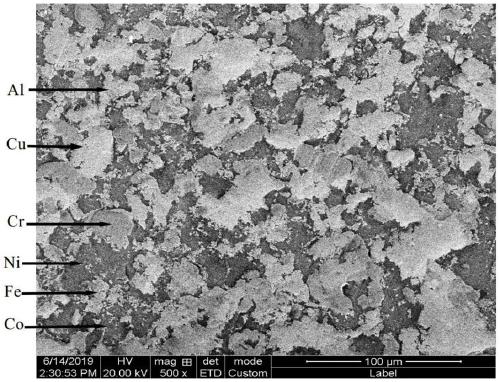

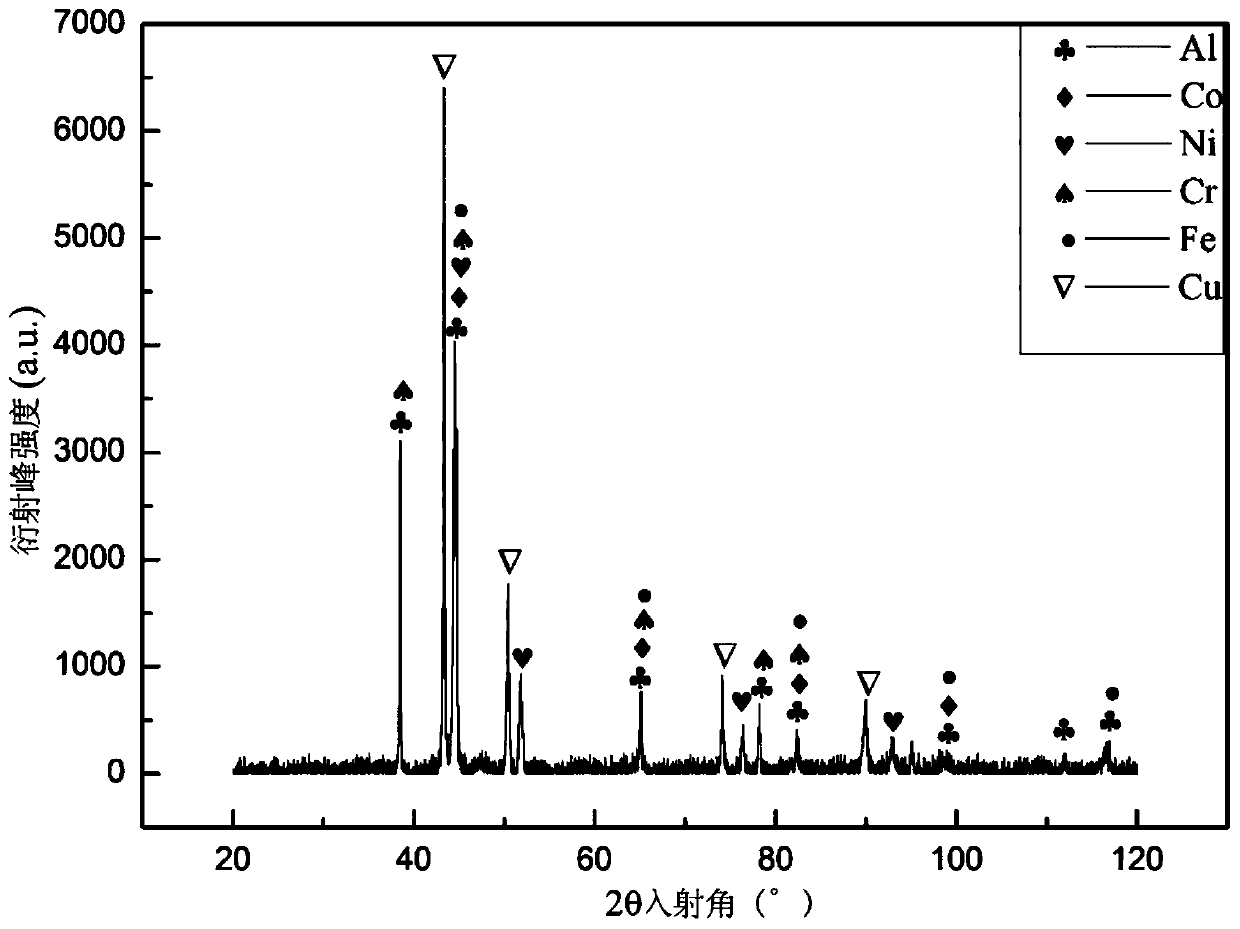

[0030] S1, Cu powder, Ni powder, Co powder, Fe powder, Cr powder and Al powder are mechanically stirred and mixed for 6.8h, and mixed uniformly to obtain a powder for cold spray; the powder for cold spray consists of the following mass fraction Raw materials: 18% Cu powder, 16% Ni powder, 16% Co powder, 15% Fe powder, 14% Cr powder, and the balance is Al powder; The powder of spherical particles; the Ni powder is a powder of irregular shape particles prepared by electrolysis; the Cr powder is a powder of irregular polygon particles prepared by crushing method; The Co powder is a powder whose appearance is an irregular particle prepared by an electrolytic method; the Fe powder is a powder whose appearance is an irregular particle prepared by an electrolytic method; the Cu powder is prepared by an electrolytic method ...

Embodiment 2

[0038] In-situ synthesis of low pressure cold spray CuNiCoFeCrAl in this example 2.8 A method for preparing a high-entropy alloy coating, the method comprising:

[0039] S1, Cu powder, Ni powder, Co powder, Fe powder, Cr powder and Al powder are mechanically stirred and mixed for 6.5h, and mixed uniformly to obtain a powder for cold spray; the powder for cold spray consists of the following mass fraction Raw materials: 15% Cu powder, 13% Ni powder, 13% Co powder, 17% Fe powder, 16% Cr powder, and the balance is Al powder; The powder of spherical particles; the Ni powder is a powder of irregular shape particles prepared by electrolysis; the Cr powder is a powder of irregular polygon particles prepared by crushing method; The Co powder is a powder whose appearance is an irregular particle prepared by an electrolytic method; the Fe powder is a powder whose appearance is an irregular particle prepared by an electrolytic method; the Cu powder is prepared by an electrolytic method ...

Embodiment 3

[0044] In-situ synthesis of low pressure cold spray CuNiCoFeCrAl in this example 2.8 A method for preparing a high-entropy alloy coating, the method comprising:

[0045] S1, Cu powder, Ni powder, Co powder, Fe powder, Cr powder and Al powder are mechanically stirred and mixed for 7 hours, and mixed uniformly to obtain a powder for cold spray; the powder for cold spray is composed of the following mass fraction of raw materials Made: 20% of Cu powder, 18% of Ni powder, 18% of Co powder, 12% of Fe powder, 11% of Cr powder, and the balance is Al powder; the Al powder is prepared by atomization method and its appearance is spherical The powder of particles; the Ni powder is a powder whose appearance is an irregular particle prepared by an electrolytic method; the Cr powder is a powder whose appearance is an irregular polygonal particle prepared by a crushing method; the Co The powder is a powder with irregular shape particles prepared by electrolysis; the Fe powder is a powder wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com