High strength intelligent integrated grid welding equipment control system

A technology of welding equipment and control system, which is applied in the field of high-strength intelligent overall grid welding equipment control system, can solve the problems of single function and poor welding precision, solve the problems of complex wiring, improve the degree of intelligence, and increase the controllability of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

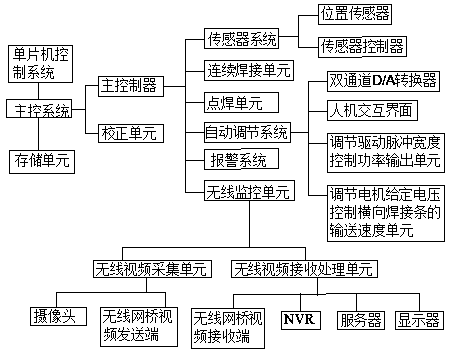

[0017] The high-strength intelligent overall grid welding equipment control system described in this embodiment has a main structure including a main control system, a sensor system, an automatic adjustment system, an alarm system, and a wireless monitoring unit; the main control system is used for information processing and welding Control, its structure comprises single-chip microcomputer control system and main controller, and single-chip microcomputer control system is electrically connected with main controller; The device is electrically connected; the alarm system is electrically connected with the automatic adjustment system.

[0018] The sensor system described in this embodiment includes a position sensor and a sensor controller; the position sensor is arranged on the welding part of the welding device, and is electrically connected with the sensor controller, and is used to accurately locate the welding point, so that the welding point and The welding torch is match...

Embodiment 2

[0025] In the high-strength intelligent overall grid welding equipment control system described in this embodiment, the method for realizing the overall grid welding is: according to the welding requirements, the range between the welding route and the welding point, the pulse width control power and the transmission of the horizontal welding strip Enter the speed into the human-computer interaction interface; turn on the high-strength intelligent overall grid welding equipment control system, control the drive of the welding device through the main control system, and transport the overall grid welding workpiece to the designated station; The positions are all equipped with position sensors, through which the preset welding points are detected, and the monitoring data are sent to the single-chip control system for analog signal conversion, and then sent to the main controller, which controls the welding torch of the welding device to Welding at the desired position; during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com