1.0-micron ultralow-noise single-frequency optical fiber laser

A fiber laser, ultra-low noise technology, used in lasers, phonon exciters, laser components and other directions, can solve the problems of complex structure, low-frequency noise degradation, and lack of full fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

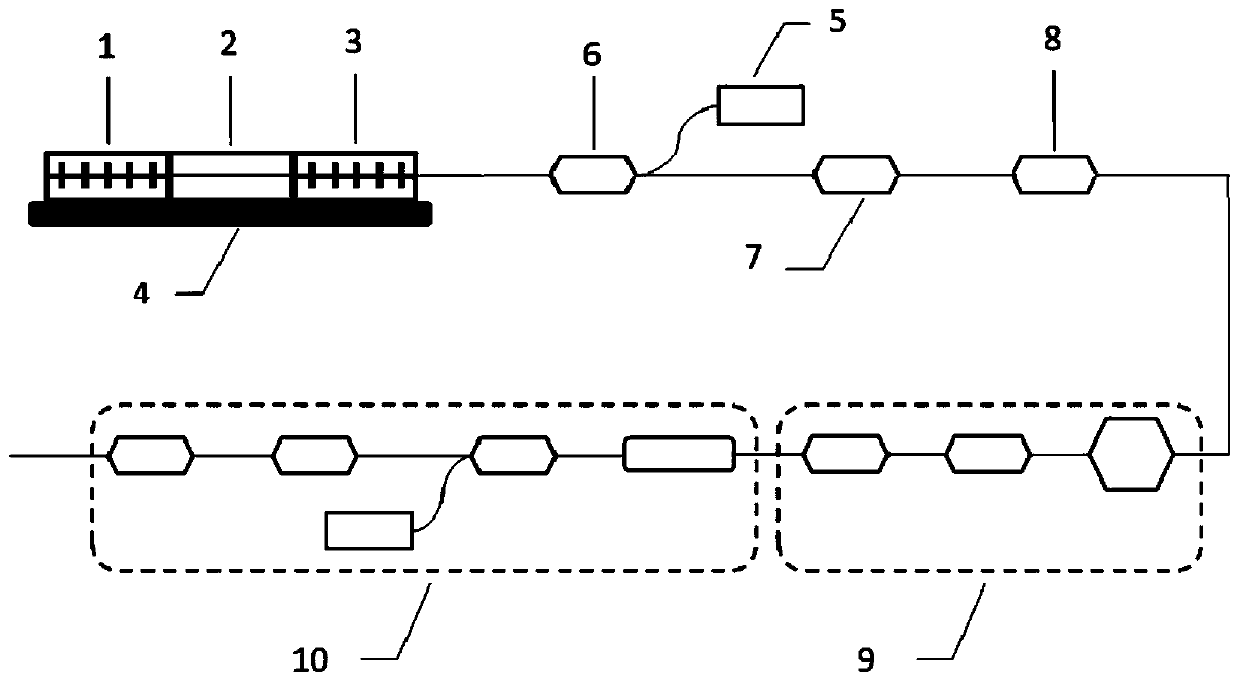

[0030] Such as figure 1 As shown, embodiment 1 provides a 1.0 μm ultra-low noise single-frequency fiber laser, which includes high reflectivity fiber Bragg grating 1, high gain fiber 2, low reflectivity fiber Bragg grating 3, TEC thermoelectric cooler 4, pump Pu laser 5, optical wavelength division multiplexer 6, optical filter 7, optical isolator 8, mid-band intensity noise suppression module 9, and low-band intensity noise suppression module 10.

[0031] The structural relationship between the above components is: one end of the high-reflectivity fiber Bragg grating, two ends of the high-gain fiber, and one end of the low-reflectivity fiber Bragg grating, which are connected in sequence to form the DBR short-line type of the laser. The resonant cavity is placed in a TEC thermoelectric cooler for precise temperature control; the other end of the low reflectivity fiber Bragg grating is connected to the common end of the optical wavelength division multiplexer, and the output end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com