Method for improving grass carp myofibrillar protein gel property

A technology for myofibrillar protein and grass carp, which is applied in the protein composition of fish, animal protein processing, protein food composition, etc., can solve problems such as poor taste and tenderness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

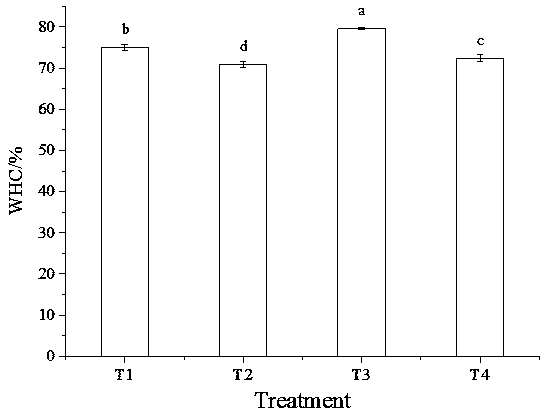

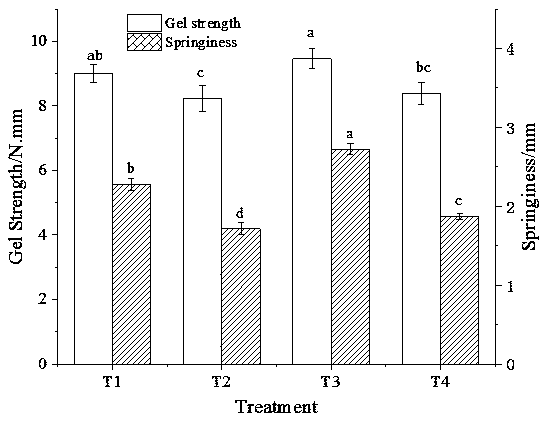

Examples

Embodiment 1

[0066] After cleaning the commercial grass carp that meets the specification requirements, remove the fish head and internal organs, then remove the fish skin and fish bones, then cut the fish meat into pieces and chop into surimi; measure the surimi with a quality of 100g;

[0067] Prepare 2 L of 51.5 mM isolated phosphate buffer solution relative to the mass of minced meat; 2 L of isolated phosphate buffer solution has a pH of 6.9-7.2; contains 0.09-0.11 M NaCl, 1.9-2.2 mM MgCl 2 And 0.8 ~ 1.1mM EDTA standby;

[0068] Prepare 2 L of 0.09M NaCl solution; the pH of the NaCl solution is 6.9-7.1; set aside;

[0069] Prepare 1 L of 21.5mM suspended phosphate buffer; the pH of 1 L of suspended phosphate buffer is 5.9-6.1, containing 0.4-0.7 M NaCl, for later use; adjust with HCl when the pH is too high, and use NaOH when the pH is too low Make adjustments.

[0070] Add 3 to 5 times the mass volume of 51.5mM phosphate buffer saline to the surimi, homogenize, centrifuge and discar...

Embodiment 2

[0077] After cleaning the commercial grass carp that meets the specification requirements, remove the fish head and internal organs, then remove the fish skin and fish bones, then cut the fish meat into pieces and chop into surimi; measure the surimi with a quality of 100g;

[0078] Prepare 2 L of 49.5 mM isolated phosphate buffer solution relative to the mass of minced meat; the pH of 2 L of isolated phosphate buffer solution is 6.9-7.2; it contains 0.09-0.11 M NaCl, 1.9-2.2 mM MgCl 2 And 0.8 ~ 1.1mM EDTA standby;

[0079]Prepare 2 L of 0.10M NaCl solution; the pH of the NaCl solution is 6.9-7.1; set aside;

[0080] Prepare 1 L of 18.5mM suspended phosphate buffer; 1 L of suspended phosphate buffer has a pH of 5.9-6.1 and contains 0.4-0.7 M NaCl, for later use;

[0081] Add 3 to 5 times the mass volume of 49.5mM isolated phosphate buffer to the surimi, homogenize, centrifuge and discard the supernatant; repeat 3 times to obtain a precipitate;

[0082] Add 3 to 5 times the v...

Embodiment 3

[0088] After cleaning the commercial grass carp that meets the specification requirements, remove the fish head and internal organs, then remove the fish skin and fish bones, then cut the fish meat into pieces and chop into surimi; measure the surimi with a quality of 100g;

[0089] Prepare 2 L of 50.5 mM isolated phosphate buffer solution relative to the mass of minced meat; 2 L of isolated phosphate buffer solution has a pH of 6.9-7.2; contains 0.09-0.11 M NaCl, 1.9-2.2 mM MgCl 2 And 0.8 ~ 1.1mM EDTA standby;

[0090] Prepare 2 L of 0.11M NaCl solution; the pH of the NaCl solution is 6.9-7.1; set aside;

[0091] Prepare 1 L of 20.5mM suspended phosphate buffer; 1 L of suspended phosphate buffer has a pH of 5.9 to 6.1 and contains 0.4 to 0.7 M NaCl, for later use;

[0092] Add 3 to 5 times the mass volume of 51.5mM isolated phosphate buffer to the surimi, homogenize, centrifuge and discard the supernatant; repeat 3 times to obtain a precipitate;

[0093] Add 3 to 5 times th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com