G-level oil well cement clinker with converter slag as raw material and preparation method of G-level oil well cement clinker

A technology of oil well cement and converter slag, which is applied in the direction of cement production, etc., can solve the problems of easily restricted product life cycle and high production cost, and achieve the effects of good strength and stability, stable quality, and reduced carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

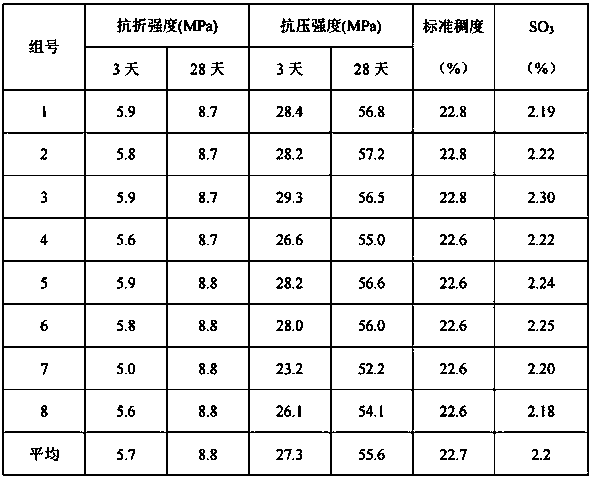

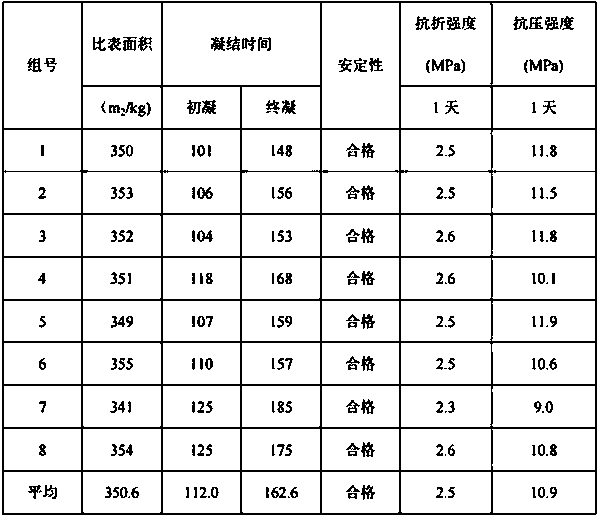

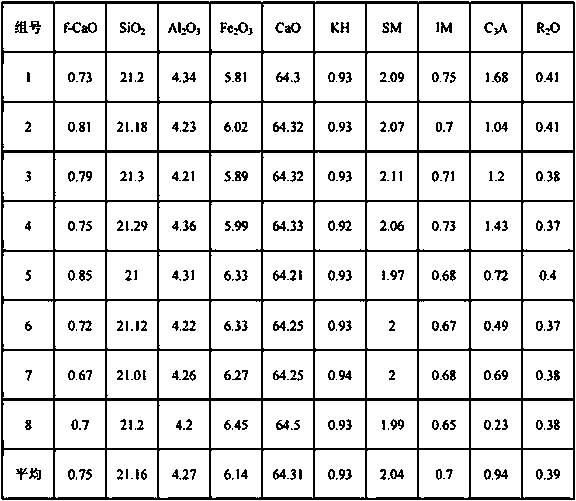

Examples

Embodiment 1

[0027] This embodiment provides a G grade oil well cement clinker using converter slag as a raw material and a preparation method thereof. Specifically, the preparation method of the G grade oil well cement clinker includes the following steps:

[0028] S1. Weigh 0.65t of limestone, 0.22t of converter slag, 0.04t of bauxite and 0.09t of silica for later use; wherein, Fe in converter slag 2 o 3 The mass fraction is 18%.

[0029] S2. Mix the above-mentioned weighed limestone, converter slag, bauxite and silica, and grind until the sieve residue after passing through an 80 μm square hole sieve is 5%, to obtain raw meal.

[0030] S3. After homogenizing the raw meal, use the five-stage cyclone pre-decomposition system of the existing dry process cement kiln system to perform preheating and decomposition treatment. The temperature of the preheating and decomposition treatment is controlled at 850°C. Specifically, the decomposition The outlet temperature of the furnace is 850°C; th...

Embodiment 2

[0034] This embodiment provides a G grade oil well cement clinker using converter slag as a raw material and a preparation method thereof. Specifically, the preparation method of the G grade oil well cement clinker includes the following steps:

[0035] S1. Weigh 0.81t of limestone, 0.14t of converter slag, 0.01t of bauxite and 0.04t of silica for subsequent use; wherein, Fe in converter slag 2 o 3 The mass fraction of is 22%.

[0036] S2. Mix the above-mentioned weighed limestone, converter slag, bauxite and silica, and grind until the sieve residue after passing through an 80 μm square hole sieve is 18%, to obtain raw meal.

[0037] S3. After homogenizing the raw meal, use the five-stage cyclone pre-decomposition system of the existing dry process cement kiln system to perform preheating and decomposition treatment. The temperature of the preheating and decomposition treatment is controlled at 880°C. Specifically, the decomposition The outlet temperature of the furnace is ...

Embodiment 3

[0041] This embodiment provides a G grade oil well cement clinker using converter slag as a raw material and a preparation method thereof. Specifically, the preparation method of the G grade oil well cement clinker includes the following steps:

[0042] S1. Weigh 0.71t of limestone, 0.18t of converter slag, 0.03t of bauxite and 0.08t of silica for later use; wherein, Fe in converter slag 2 o 3 The mass fraction is 20%.

[0043] S2. Mix the above-mentioned weighed limestone, converter slag, bauxite and silica, and grind until the sieve residue after passing through an 80 μm square hole sieve is 10%, to obtain raw meal.

[0044] S3. After homogenizing the raw meal, use the five-stage cyclone pre-decomposition system of the existing dry process cement kiln system to perform preheating and decomposition treatment, wherein the temperature of the preheating and decomposition treatment is controlled at 870°C. The outlet temperature of the furnace is 870°C; the outlet temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com