Polyurethane, preparation method and applications thereof

A technology of polyurethane and urethane, applied in polyurea/polyurethane coatings, textiles and papermaking, coatings, etc., can solve the problems of no marine antifouling research, significant antifouling effect, high swelling rate, etc., and achieve outstanding anti-algae Adhesion performance, excellent anti-biofouling performance, anti-biofouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

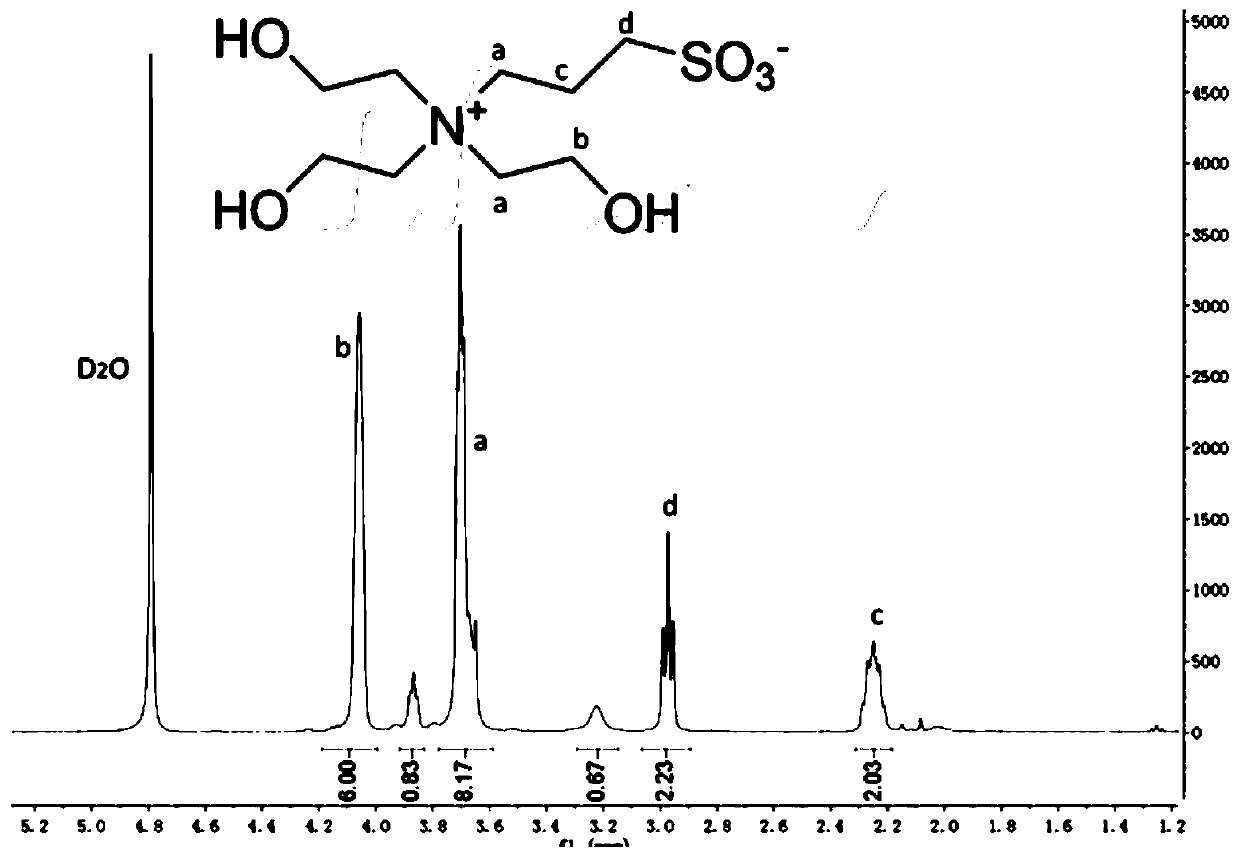

[0056] The preparation process of THEAPS is as follows: Weigh 10g of 1,3-propane sultone, put it into a 100mL round bottom flask, then pour 30mL of ethyl acetate solvent into it, heat and stir in a water bath at 40°C, and put 10g of triethanolamine into a separatory funnel Slowly add it dropwise to the system, carry out 24 hours of sufficient reaction, carry out vacuum suction filtration, and wash three times with ethyl acetate to obtain white THEAPS crystals and dry them in a vacuum oven. The H NMR spectrum is as follows figure 1 shown.

[0057]

[0058] Weigh 1.5g THEAPS, 4.5g polyethylene glycol (PEG) (Mn=600) and 0.5g polycaprolactone diol (PCL) (Mn=1000) into a 100mL round bottom flask and vacuum dehydrate at 120°C for 2 hour, then add 20mL of DMF solvent that has been dried and dehydrated, heat and stir at 40°C to dissolve, then add 2.5g of hexamethylene diisocyanate, raise the temperature to 80°C and stir the reaction under nitrogen protection for 1 hour to form a po...

Embodiment 2

[0060] The preparation process of THEAPS is as follows: Weigh 10g of 1,3-propane sultone, put it into a 100mL round bottom flask, then pour 30mL of ethyl acetate solvent into it, heat and stir in a water bath at 40°C, and put 10g of triethanolamine into a separatory funnel It was slowly added dropwise to the system, and after 24 hours of sufficient reaction, it was filtered under reduced pressure and washed three times with ethyl acetate to obtain white crystals, which were dried in a vacuum oven.

[0061] Weigh 1.5g THEAPS, 4.5g polyethylene glycol (PEG) (Mn=1000) and 0.5g polycarbonate diol (PCDL) (Mn=1000) into a 100mL round bottom flask and dehydrate under vacuum at 120°C for 2 hours , then add 20mL of DMF solvent that has been dehydrated, heat and stir at 40°C to dissolve, then add 2.5g of hexamethylene diisocyanate, raise the temperature to 80°C and stir for 1 hour under nitrogen protection to form a polyurethane prepolymer . Then, 0.184 g of ethylene glycol was added t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com