A kind of underwater self-healing organosilicon antifouling coating and preparation method thereof

An antifouling coating and silicone technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of low substrate adhesion and poor mechanical properties, and achieve improved adhesion, Strong practicability, simple and efficient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

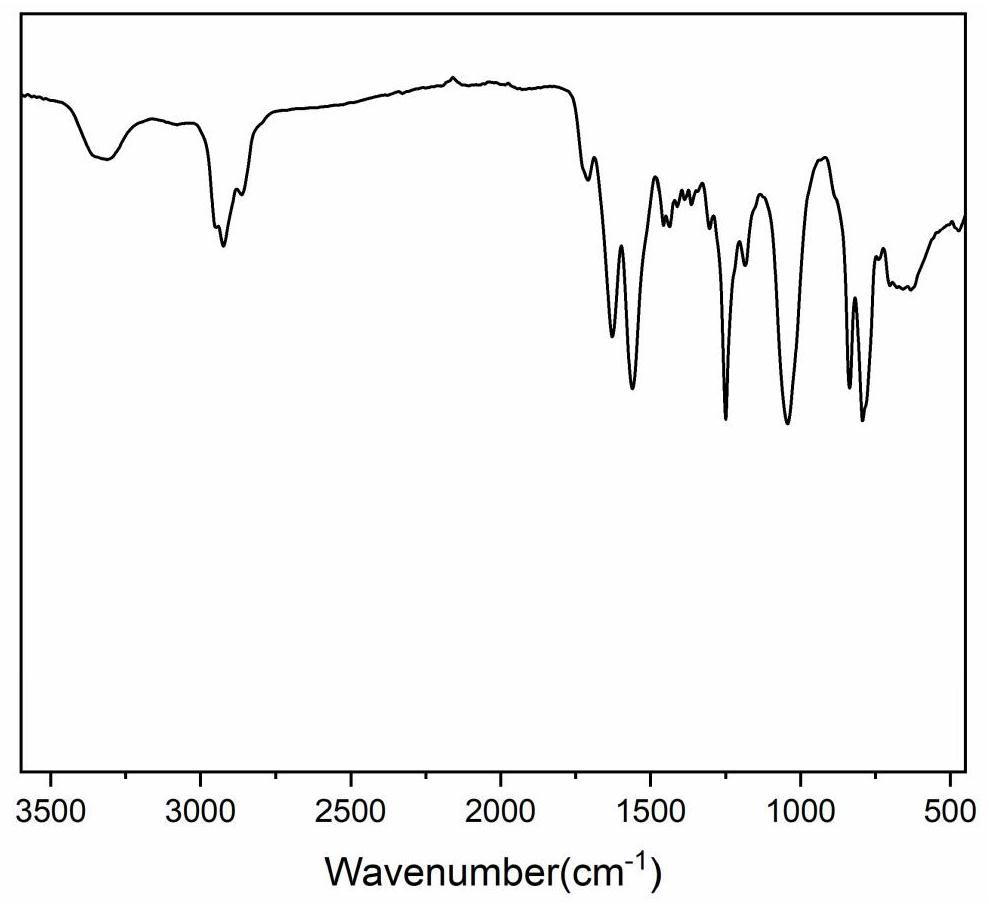

[0043] A preparation method of underwater self-repairing organic silicon antifouling coating is carried out according to the following steps:

[0044] Step 1: first dissolve a certain amount of dopamine hydrochloride in a large amount of absolute ethanol (making the concentration of dopamine hydrochloride 0.05mol / L) under a nitrogen atmosphere, then add a certain amount of triethylamine to neutralize the hydrochloric acid at room temperature Hydrochloride in dopamine. Add a certain amount of condensing agent 2-ethoxy-1-ethoxycarbonyl-1,2-dihydroquinoline and α-lipoic acid or / and its derivatives to condense with dopamine at room temperature for 24 hours after reacting for 1 hour , so as to obtain catechol functionalized lipoic acid derivatives;

[0045] Step 2: reacting excess amino-terminated polysiloxane with diisocyanate in a mixed solution of isopropanol and tetrahydrofuran for 3 hours to generate amino-terminated polysiloxane containing urea bonds. Then add a certain amo...

Embodiment 1

[0048] (1) Add 1.5 g of triethylamine dropwise to a three-necked flask containing 2.8 g of dopamine hydrochloride and 300 mL of absolute ethanol under a nitrogen atmosphere, and react at room temperature for 1 h. Then add 3.1g of α-lipoic acid and 3.7g of 2-ethoxy-1-ethoxycarbonyl-1,2-dihydroquinoline, and react at room temperature for 24h, and finally obtain phthalate as a yellow oily liquid Phenol-functionalized lipoic acid.

[0049] (2) Dissolve 3g of 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane in a mixed solvent of 13.5g of isopropanol and 13.5g of tetrahydrofuran under constant pressure The dropping funnel was added dropwise to a three-necked flask containing 2.2 g of isophorone diisocyanate dissolved in a mixed solvent of 10 g of isopropanol and 10 g of tetrahydrofuran. After the addition was completed, it was reacted at room temperature for 3 hours, and then 4.9 g of α-lipoic acid was added. React at 45°C for 6 hours to obtain diisocyanate-modified siloxane li...

Embodiment 2~11 and comparative example 1

[0053] Except for changing the types and amounts of monomers / prepolymers, crosslinking agents, metal salts and antifouling agents, the rest of the steps and conditions were the same as in Example 1 to obtain different antifouling coatings, see Table 1 for details. The amino double head in the table refers to 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane, and the amino-terminated silicone oil (3000Mw, 10000Mw and 20000Mw) refers to different Molecular weight amoterminated polysiloxane.

[0054] Table 1

[0055]

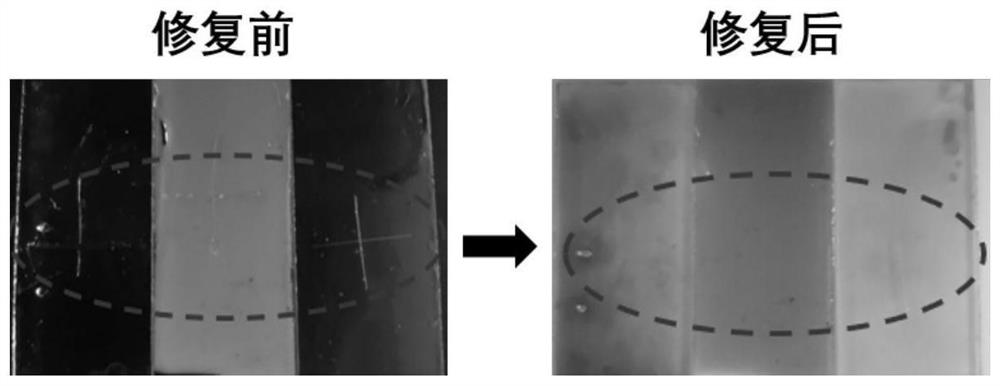

[0056] In order to evaluate the static antifouling effect of the present invention, the method of actual sea hanging board test has been adopted, with reference to GB / T5370-2007 (antifouling paint model shallow sea immersion test method) the antifouling coating system prepared in the embodiment is immersed Qingdao coastal water, investigated its antifouling performance (see image 3 ), scored according to the adhesion area of fouling organisms on the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com