Preparation method and application of anti-corrosion and anti-fouling integrated coating with self-repairing function

A self-healing and coating technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve problems such as accelerated electrode reaction, accelerated metal fouling, lack of antibacterial and anti-biofouling, etc. It achieves the effects of simple and efficient preparation process, excellent antibacterial and anti-biofouling properties, and good self-healing and anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

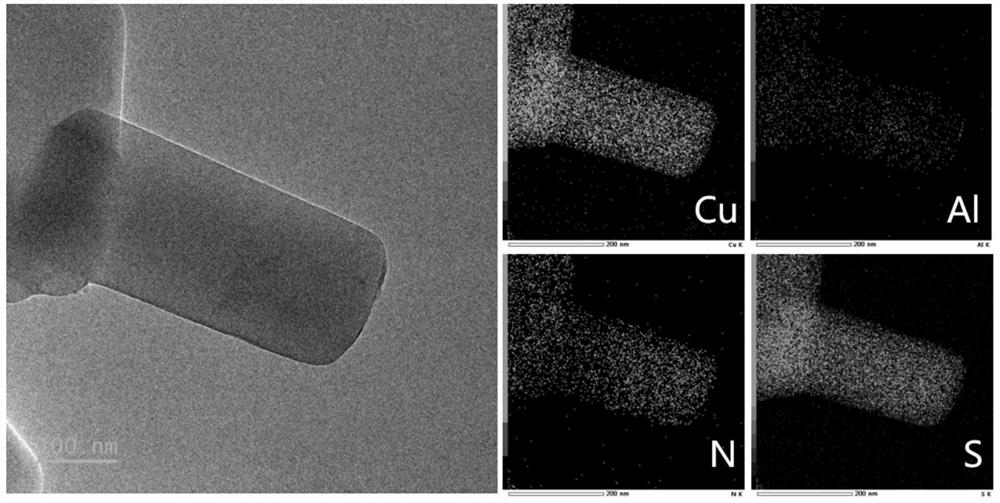

[0042] Example 1 Preparation of a bimetallic intercalation material loaded with a small molecule slow-release fungicide

[0043] (1) Accurately weigh 2.17g copper nitrate trihydrate and 1.69g aluminum nitrate nonahydrate and join in the beaker that 45mL deionized water and 15mL dimethyl sulfoxide mixed solution are housed, add 0.72g urea after fully stirring and dissolving, then Transfer the above mixed solution to a hydrothermal reaction kettle for hydrothermal reaction at 110°C for 12 hours, centrifuge, wash and dry after the reaction to obtain a copper-aluminum bimetallic intercalation material;

[0044] (2) Take 250 mg of the above-mentioned copper-aluminum bimetallic intercalation material and disperse it in 250 mL of deionized water, then slowly add 80 μL of sodium pyrithione ethanol solution with a concentration of 10 g / L to the dispersion, react at room temperature for 4 hours, and then Centrifuge, wash and dry to obtain the bimetallic intercalation material loaded wit...

Embodiment 2

[0045] Example 2 Preparation of a bimetallic intercalation material loaded with a small molecule slow-release fungicide

[0046] (1) Add 5.13g (2mmol) magnesium nitrate hexahydrate and 3.75g (1mmol) aluminum nitrate nonahydrate to a beaker containing 70mL deionized water, stir and dissolve, add 0.42g urea (7mmol), and then add the above The mixed solution was transferred to a hydrothermal reaction kettle for hydrothermal reaction at 140°C for 8 hours, and after the reaction, it was centrifuged, washed and dried to obtain a magnesium-aluminum bimetallic intercalation material;

[0047] (2) Take 100 mg of the above-mentioned magnesium-aluminum bimetallic intercalation material and disperse it in 100 mL of deionized water, then slowly add 32 μL of ethanol solution of sodium pyrithione with a concentration of 10 g / L to the dispersion, and react at room temperature for 4 hours. Centrifuge, wash and dry to obtain the bimetallic intercalation material loaded with small molecule slow-...

Embodiment 3

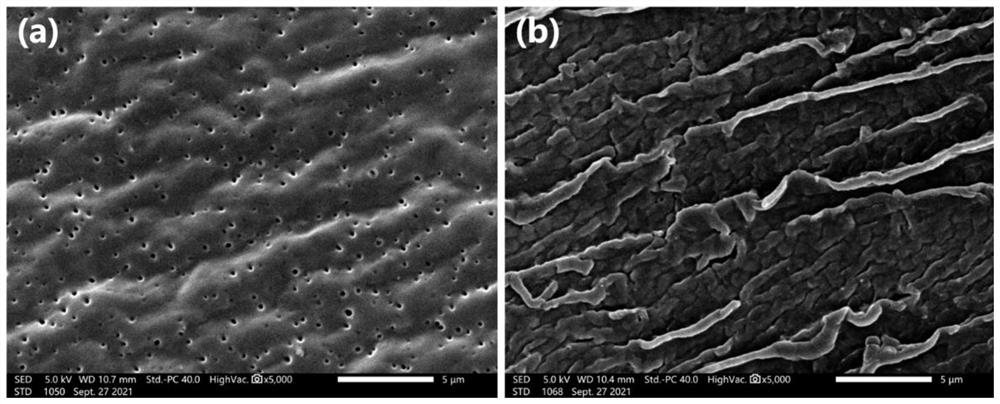

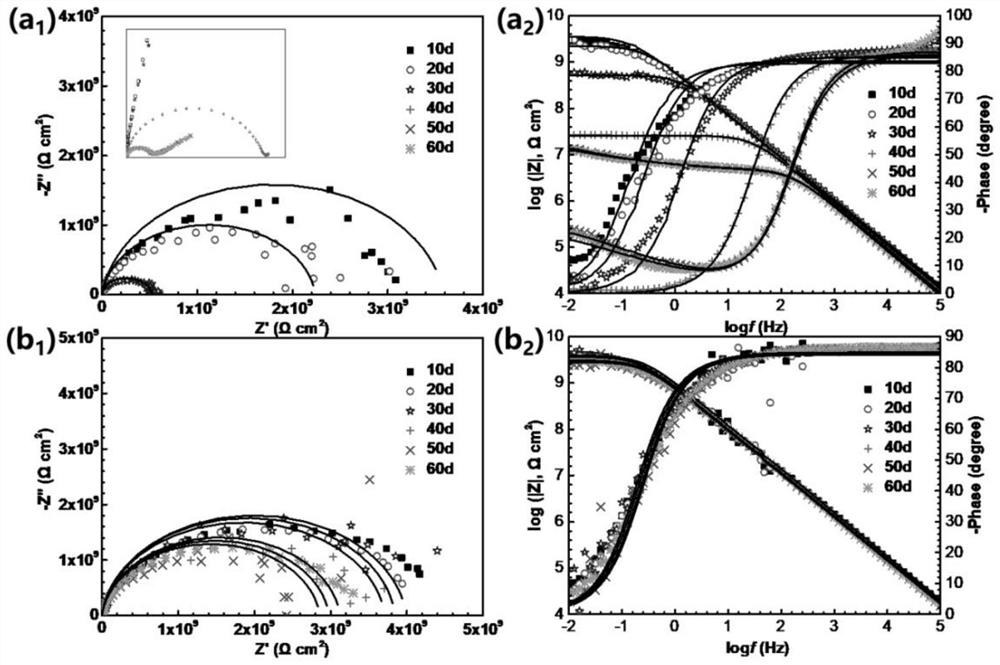

[0049] Example 3 Preparation and effect verification of anti-corrosion and anti-fouling integrated coating with self-repair function

[0050] 1. Preparation of anti-corrosion and anti-fouling integrated coating with self-healing function

[0051] Accurately weigh 25 mg of the bimetallic intercalation material loaded with small molecule slow-release bactericide prepared in Example 1 and add it to 4 g of epoxy resin, ultrasonically disperse for 30 min, then add 1 g of epoxy resin curing agent, and vacuum defoam for 10 min after fully stirring , to prepare an anti-corrosion and anti-fouling integrated coating with self-repairing function.

[0052] Coat the above-mentioned anti-corrosion and anti-fouling integrated coating on the surface of the prepared carbon steel electrode, and after being completely cured, make a bimetallic intercalation material coating with a loaded corrosion inhibitor, that is, an integrated anti-corrosion and anti-fouling with self-repairing function coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com