Calcium carbonate rare earth mixed filler and production method thereof

A technology of mixing fillers and calcium carbonate, which is applied in the field of calcium carbonate fillers, can solve the problems affecting the dispersion of nano-calcium carbonate, large surface activity, etc., and achieve the effects of increasing thermal stability, chemical corrosion resistance, good stability, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 200 parts of nano-calcium carbonate, 3 parts of carbon black powder, 8 parts of aluminum-zirconium coupling agent, 8 parts of zinc oxide, 6 parts of molybdenum carbide, 6 parts of sodium stearate, 5 parts of castor oil phosphate, and 12 parts of polystyrene , 5 parts of polyurethane, 18 parts of acrylic resin, 28 parts of epoxy resin, 4 parts of surface treatment agent, appropriate amount of methanol, and appropriate amount of deionized water.

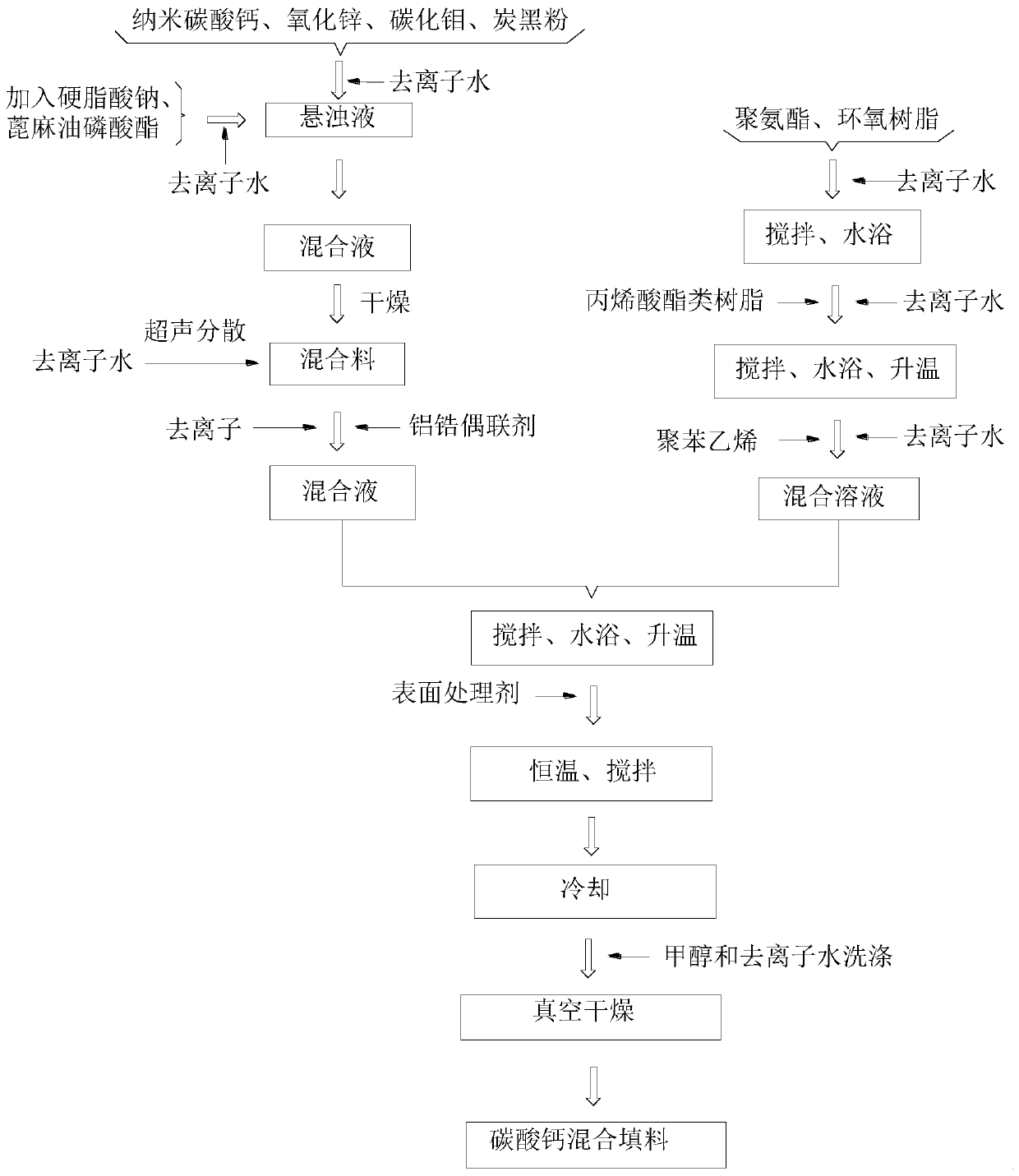

[0025] see figure 1 , according to above-mentioned raw material, the production method that calcium carbonate rare earth mixed filler is provided, comprises the following steps:

[0026] The first step: 200 parts of nano-calcium carbonate, 8 parts of zinc oxide, 6 parts of molybdenum carbide and 3 parts of carbon black powder are placed in deionized water with a weight 5-6 times that of nano-calcium carbonate to form a suspension. Add 6 parts of sodium stearate, 5 parts of castor oil phosphate and deionized water equivalen...

Embodiment 2

[0032]Take 200 parts of nano-calcium carbonate, 5 parts of carbon black powder, 10 parts of aluminum-zirconium coupling agent, 10 parts of zinc oxide, 8 parts of molybdenum carbide, 8 parts of sodium stearate, 6 parts of castor oil phosphate, and 15 parts of polystyrene , 6 parts of polyurethane, 25 parts of acrylic resin, 35 parts of epoxy resin, 5 parts of surface treatment agent, appropriate amount of methanol, and appropriate amount of deionized water.

[0033] According to above-mentioned raw material, the production method of calcium carbonate rare earth mixed filler is provided, comprises the following steps:

[0034] The first step: 200 parts of nano-calcium carbonate, 10 parts of zinc oxide, 8 parts of molybdenum carbide and 5 parts of carbon black powder are placed in deionized water with a weight 5-6 times that of nano-calcium carbonate to form a suspension. Add 8 parts of sodium stearate, 6 parts of castor oil phosphate and deionized water equivalent to 3-4 times t...

Embodiment 3

[0040] Take 200 parts of nano-calcium carbonate, 4 parts of carbon black powder, 9 parts of aluminum-zirconium coupling agent, 9 parts of zinc oxide, 7 parts of molybdenum carbide, 7 parts of sodium stearate, 5 parts of castor oil phosphate, and 13 parts of polystyrene , 6 parts of polyurethane, 22 parts of acrylic resin, 32 parts of epoxy resin, 5 parts of surface treatment agent, appropriate amount of methanol, and appropriate amount of deionized water.

[0041] According to above-mentioned raw material, the production method of calcium carbonate rare earth mixed filler is provided, comprises the following steps:

[0042] The first step: 200 parts of nano-calcium carbonate, 9 parts of zinc oxide, 7 parts of molybdenum carbide and 4 parts of carbon black powder are placed in deionized water with a weight 5-6 times that of nano-calcium carbonate to form a suspension. Add 7 parts of sodium stearate, 5 parts of castor oil phosphate, and deionized water equivalent to 3-4 times th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com