AlGaN/GaN heterojunction Schottky diode device based on P-GaN cap layer and floating metal ring

A technology of Schottky diodes and metal rings, applied in the direction of diodes, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of slow lateral potential changes, influence of forward characteristics, increase of series resistance, etc., and achieve reverse leakage Effects of leakage current suppression, defect avoidance, and breakdown voltage improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

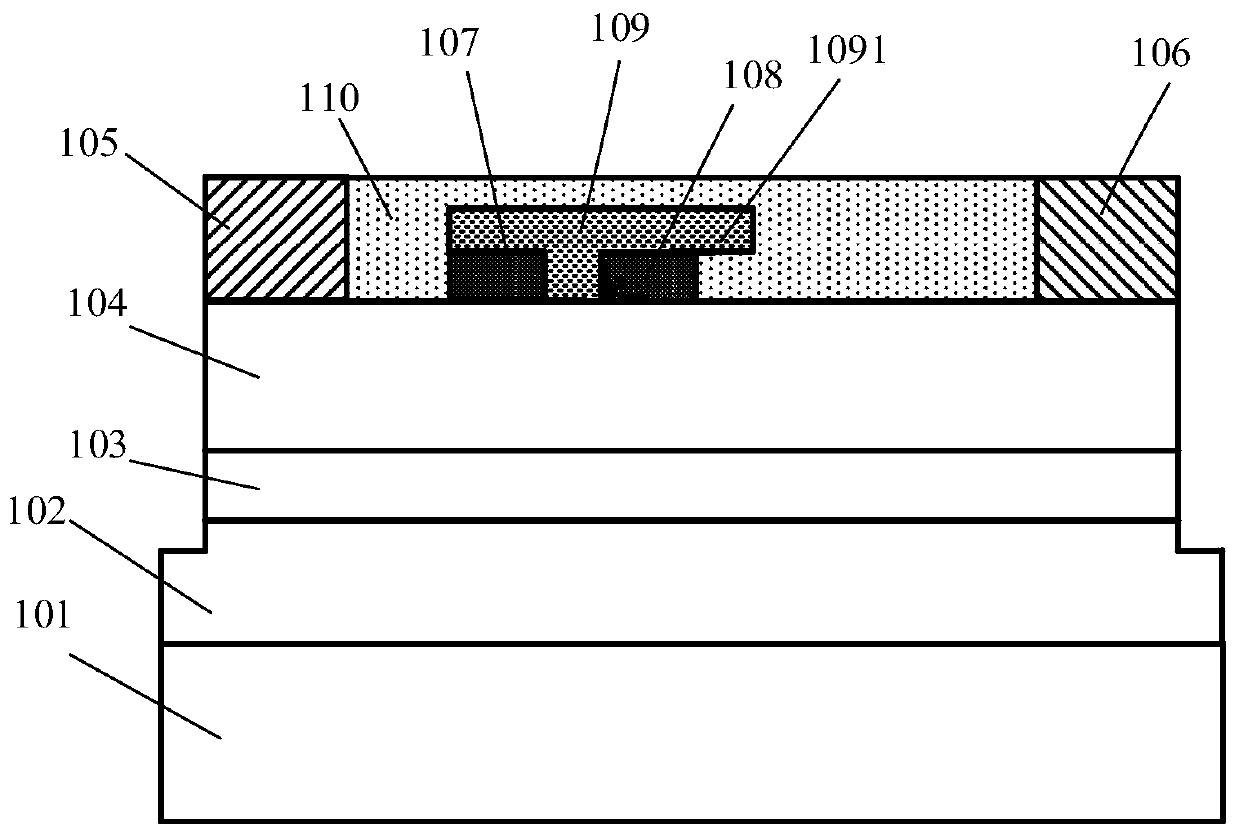

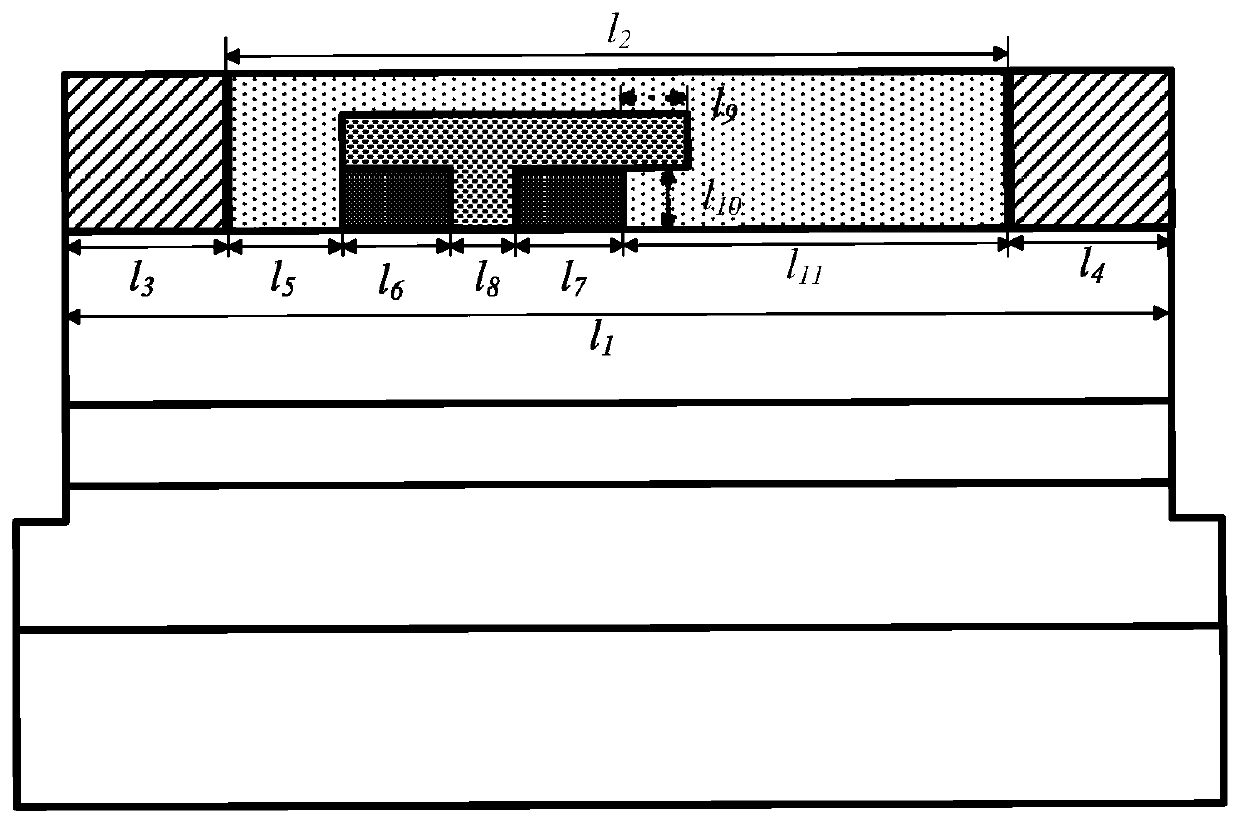

[0036] See figure 1 , figure 1It is a schematic structural diagram of an AlGaN / GaN heterojunction Schottky diode device based on a P-GaN cap layer and a floating metal ring provided by an embodiment of the present invention. The AlGaN / GaN heterojunction Schottky diode device includes a substrate 101, a GaN buffer layer 102, a channel layer 103, an AlGaN barrier layer 104, and a passivation layer 110 sequentially arranged on the substrate 101, wherein the AlGaN An anode 105 and a cathode 106 are respectively provided on opposite sides of the upper surface of the barrier layer 104, and at least one composite structure is provided on the AlGaN barrier layer 104 between the anode 105 and the cathode 106, and the composite structure includes a first P-type GaN The cap layer 107, the second P-type GaN cap layer 108 and the floating metal ring 109; the first P-type GaN cap layer 107 and the second P-type GaN cap layer 108 are arranged on the AlGaN barrier layer 104 at intervals, and...

Embodiment 2

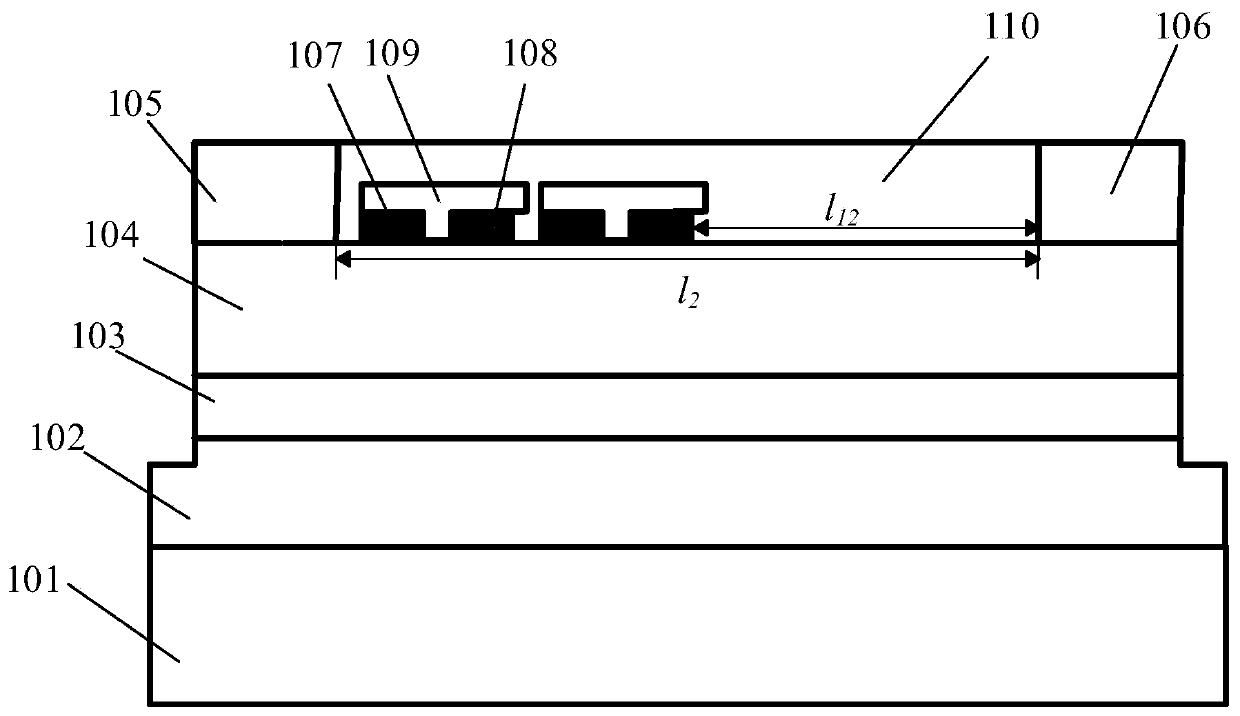

[0051] On the basis of the above embodiments, this embodiment provides another AlGaN / GaN heterojunction Schottky diode device based on a P-GaN cap layer and a floating metal ring.

[0052] As mentioned above, at least one of the combined structures is provided on the AlGaN barrier layer 104 between the anode 105 and the cathode 106, that is to say, a plurality of the above-mentioned composite structures can be provided on the AlGaN barrier layer 104 between the anode 105 and the cathode 106. the combined structure. The main difference between this embodiment and Embodiment 1 is that this embodiment may include multiple combined structures, wherein, along the direction from the anode 105 to the cathode 106, the first P-type GaN cap layer 107 of the first combined structure is located One side close to the anode 105 and spaced apart from the anode 105; the second P-type GaN cap layer 108 of the last combination structure is located on the side close to the cathode 106 and spaced...

Embodiment 3

[0060] On the basis of the above embodiments, this embodiment provides a method for manufacturing an AlGaN / GaN heterojunction Schottky diode device based on a P-GaN cap layer and a floating metal ring. See Figure 7a to Figure 7f , Figure 7a to Figure 7f It is a schematic diagram of the preparation process of an AlGaN / GaN heterojunction Schottky diode device based on a P-GaN cap layer and a floating metal ring provided by an embodiment of the present invention.

[0061] Described preparation method comprises:

[0062] Step 1: using MOCVD (metal organic vapor deposition) process to epitaxially grow the heterojunction.

[0063] 1.1) Select SiC or sapphire substrate, such as Figure 7a shown;

[0064] 1.2) On the SiC or sapphire substrate, grow an intrinsic GaN layer with a thickness of 1 μm;

[0065] 1.3) A 25nm-thick AlGaN barrier layer is grown on the intrinsic GaN layer, wherein the composition of Al is 20%, and a two-dimensional electron gas is formed at the contact po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com