A kind of acid gas trapping agent and trapping method

A technology of acid gas and trapping agent, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve problems such as corrosion and large solvent loss, achieve low desorption temperature, small solvent loss, and good economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

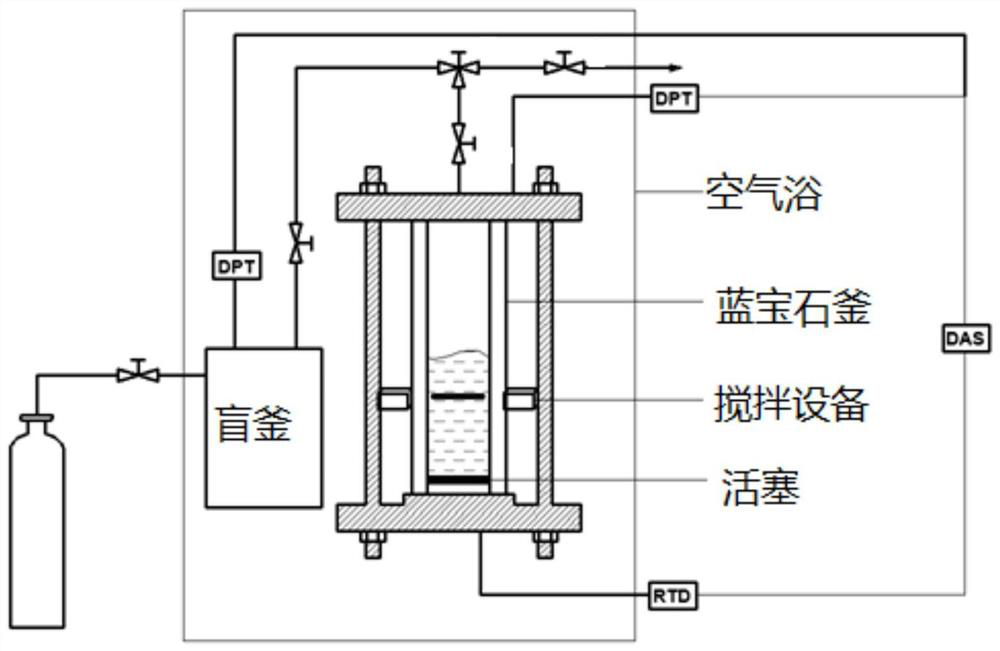

[0023] This embodiment provides a method for capturing carbon dioxide by figure 1 The shown device is completed, specifically comprising the following steps:

[0024] The acid gas trapping agent that adopts is the mixed solvent of propylene carbonate and dimethylimidazole ethylene glycol solution, and wherein, the content of dimethylimidazole ethylene glycol is 40wt%, and wherein, in dimethylimidazole ethylene glycol solution Dimethylimidazole content is 40wt%;

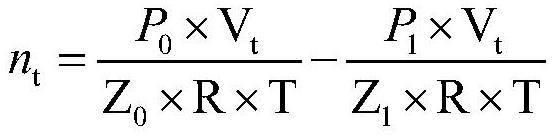

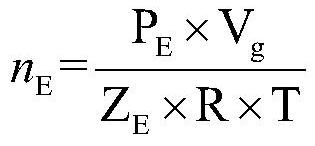

[0025] Before the experiment begins, remove the sapphire kettle, wash it with deionized water, dry it, and add a certain amount of configured collector; then fix the sapphire kettle in the air bath again, and vacuum the sapphire kettle; Vacuumize the pipeline system connected to it, replace it with the raw material gas three times and then replenish the raw material gas to a given pressure; start the constant temperature air bath to set the experimental temperature; when the temperature of the air bath reaches the ex...

Embodiment 2

[0042] In order to verify the effect of different additions of dimethylimidazole ethylene glycol solution on the CO absorption by the collector 2 The influence of effect, to three kinds of different proportionings (the addition amount of dimethylimidazole ethylene glycol solution is respectively m f =20wt%, 40wt%, 60wt%, wherein, in the dimethylimidazole ethylene glycol solution, the dimethylimidazole content is 40wt%) mixed solution CO 2 Absorption experiment.

[0043] It can be seen from the data in Table 2 that CO 2 The solubility in dimethylimidazole ethylene glycol-propylene carbonate increases with the increase of pressure, and also increases with the increase of dimethylimidazole ethylene glycol solution, especially at low pressure. These results show that the collector of this example is beneficial in some low CO 2 Capture CO under partial pressure 2 , e.g. from flue gas or biogas CO 2separation. More importantly, dimethylimidazole glycol solution has lower volat...

Embodiment 3

[0047] In order to verify that the acid gas trapping agent can be resolved at a lower temperature, the trapping agent (50% propylene carbonate, 50% dimethylimidazole ethylene glycol solution, wherein, in dimethylimidazole ethylene glycol solution The dimethylimidazole content is 40wt%) to carry out the cycle experiment, the absorption experiment condition is 20 DEG C, the pressure is as shown in Table 3, the desorption condition is 20 DEG C, vacuum.

[0048] From the data in Table 3, it can be seen that under the desorption conditions, the absorption of the trapping agent remains unchanged after one cycle, indicating that the trapping agent can be regenerated at a lower desorption temperature. Because the desorption temperature is low, the loss of the collector is small during the desorption process, and it is also observed in the experiment that there is almost no loss of the collector. The CO is calculated by the gram-gram equation (Clausius-Clapeyron equation). 2 The heat o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com