Ore dressing method for rubidium preenrichment

A beneficiation method and pre-enrichment technology, applied in flotation, solid separation, cyclone device, etc., to achieve the effect of safe and convenient use, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

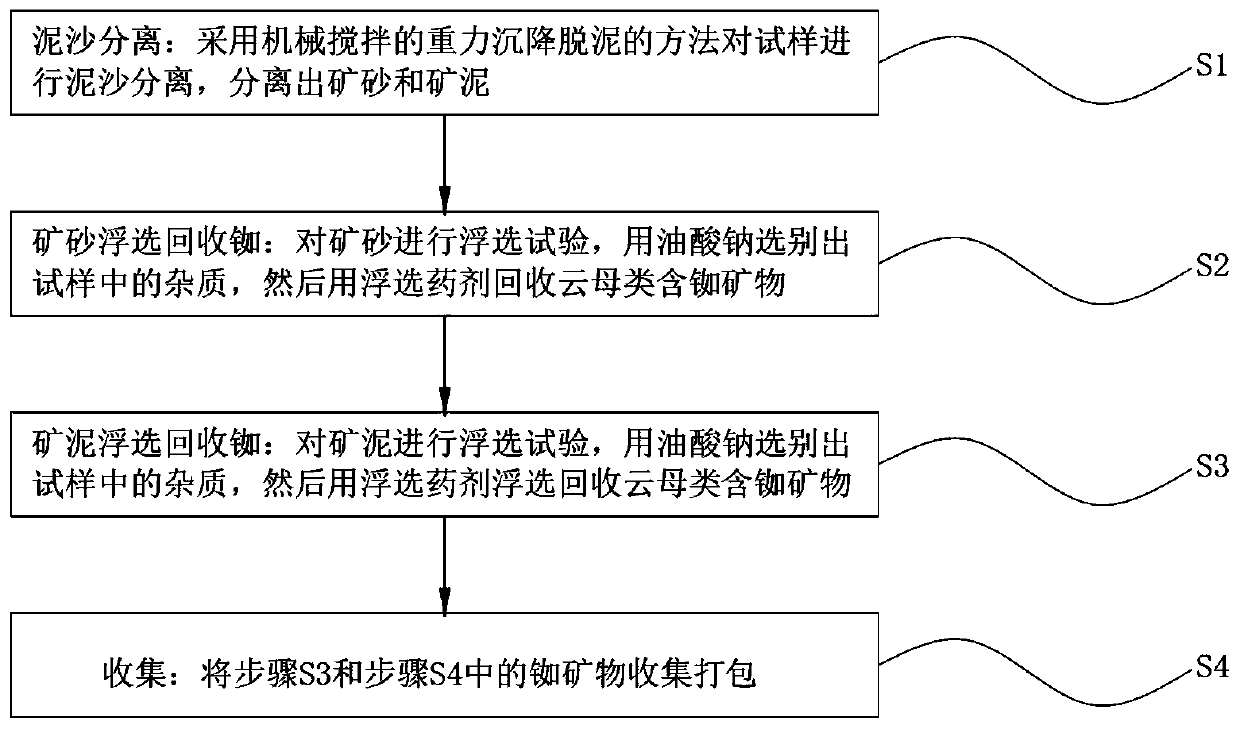

[0038] Embodiment 1: as Figure 1-5 As shown, the present invention provides technical scheme, a kind of beneficiation method of the pre-enrichment of rubidium, comprises the steps:

[0039] S1. Sediment separation: adopt the method of gravity sedimentation and desliming with mechanical agitation to separate the sediment from the sample, and separate the ore and mud;

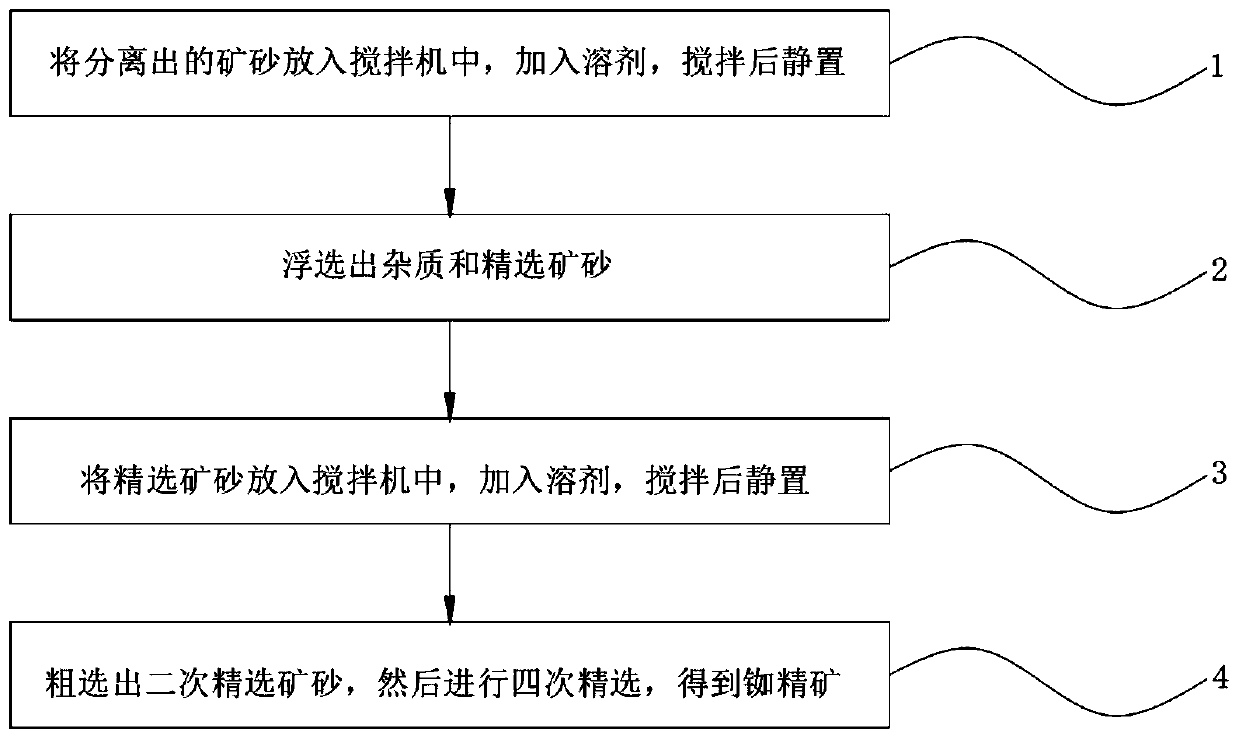

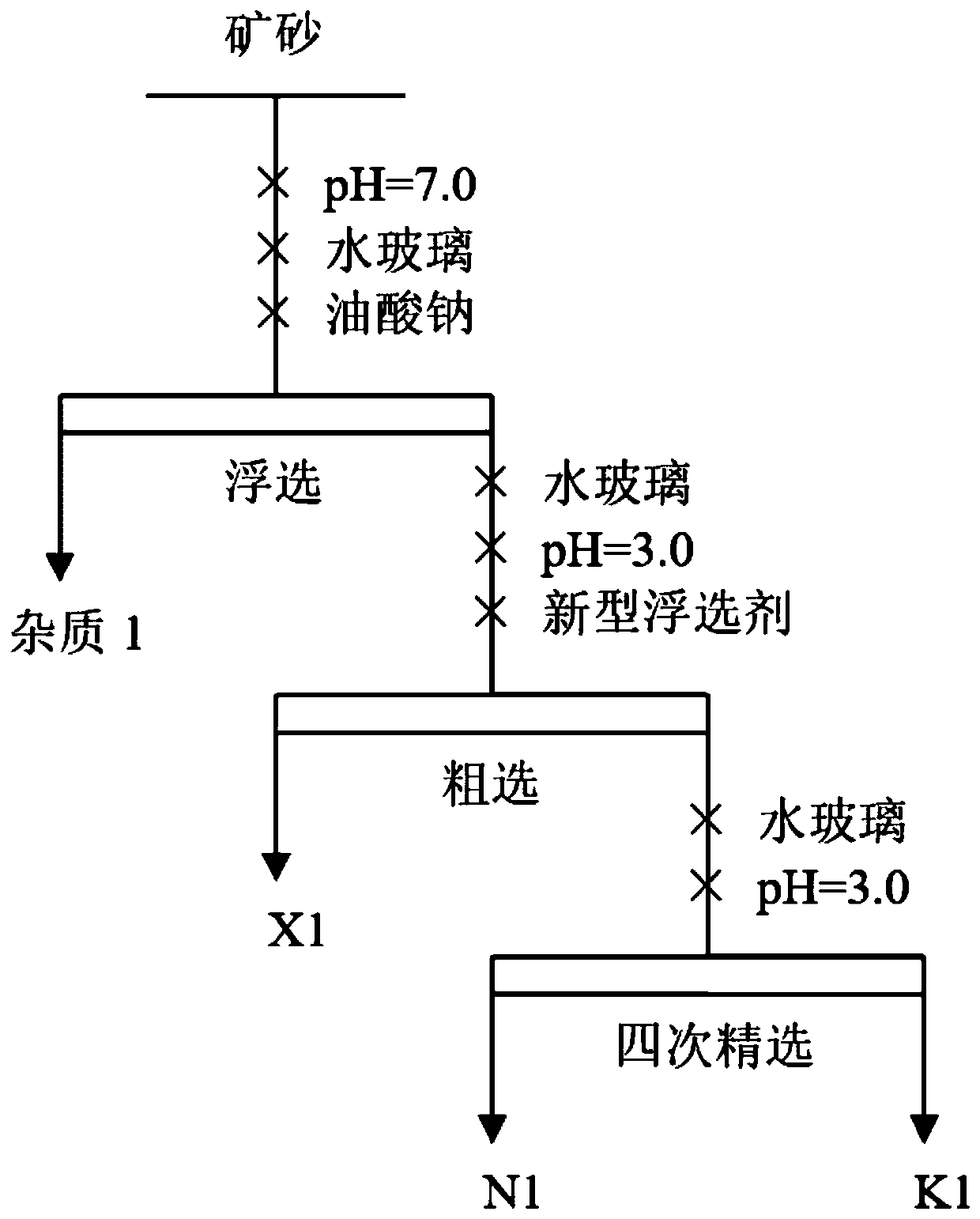

[0040] S2. Recovery of rubidium by ore sand flotation: Carry out flotation test on ore sand, use sodium oleate to separate out the impurities in the sample, and then use flotation reagents to recover mica-like rubidium-containing minerals;

[0041] S3. Slime flotation recovery of rubidium: carry out flotation test on the ore slime, use sodium oleate to separate out the impurities in the sample, and then use flotation reagents to flotation and recover mica-like rubidium-containing minerals;

[0042] S4. Collecting: collecting and packaging the rubidium minerals in steps S3 and S4.

[0043] According to the abov...

Embodiment 2

[0064] Embodiment 2: as Figure 1-5 As shown, the present invention provides technical scheme, a kind of beneficiation method of the pre-enrichment of rubidium, comprises the steps:

[0065] S1. Sediment separation: adopt the method of gravity sedimentation and desliming with mechanical agitation to separate the sediment from the sample, and separate the ore and mud;

[0066] S2. Recovery of rubidium by ore sand flotation: Carry out flotation test on ore sand, use sodium oleate to separate out the impurities in the sample, and then use flotation reagents to recover mica-like rubidium-containing minerals;

[0067] S3. Slime flotation recovery of rubidium: carry out flotation test on the ore slime, use sodium oleate to separate out the impurities in the sample, and then use flotation reagents to flotation and recover mica-like rubidium-containing minerals;

[0068] S4. Collecting: collecting and packaging the rubidium minerals in steps S3 and S4.

[0069] According to the abov...

Embodiment 3

[0090] Embodiment 3: as Figure 1-5 As shown, the present invention provides technical scheme, a kind of beneficiation method of the pre-enrichment of rubidium, comprises the steps:

[0091] S1. Sediment separation: adopt the method of gravity sedimentation and desliming with mechanical agitation to separate the sediment from the sample, and separate the ore and mud;

[0092] S2. Recovery of rubidium by ore sand flotation: Carry out flotation test on ore sand, use sodium oleate to separate out the impurities in the sample, and then use flotation reagents to recover mica-like rubidium-containing minerals;

[0093] S3. Slime flotation recovery of rubidium: carry out flotation test on the ore slime, use sodium oleate to separate out the impurities in the sample, and then use flotation reagents to flotation and recover mica-like rubidium-containing minerals;

[0094] S4. Collecting: collecting and packaging the rubidium minerals in steps S3 and S4.

[0095] According to the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com