Ancient architecture repairing grey tile firing process and system

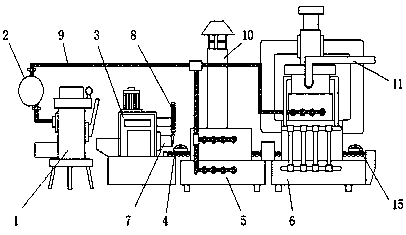

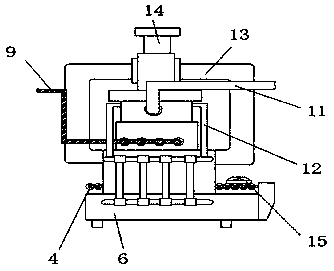

A technology for ancient buildings and blue tiles, which is applied in the field of ancient building repairing blue tile firing processes and systems, can solve problems such as unfavorable batch production of blue tiles, difficulty in uniform cooling of tap water, large labor and time consumption, etc., and achieves cooling contact The effect of wide area, increasing structural permeability and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

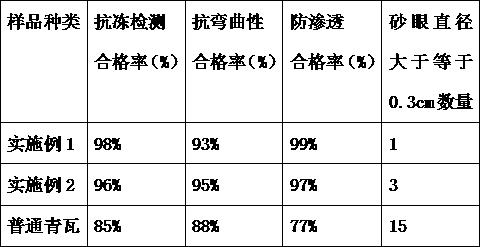

Embodiment 1

[0032] A kind of ancient building restoration blue tiles, the blue tiles are made of the following percentages of raw materials: construction waste 35%, clay 35% and coal gangue 30%; construction waste includes one of waste bricks, waste sand, waste ceramic tiles and cement Or more; the steps of the blue tile firing process are as follows:

[0033] Raw material processing: Put construction waste and coal gangue into 4E3216 Lei Meng mill for pulverization, and then use ball mill for ball milling to obtain construction waste powder and coal gangue powder with particle size less than 2 µm;

[0034] Mixing: transport 35% of clay, 35% of building powder and 30% of coal gangue powder into the planetary mixer for mixing for 1 hour. The speed of the mixing plate is controlled to 10.5 rpm, and an appropriate amount of water is added to make the mixture obtained The moisture content is controlled to 16.9%;

[0035] Extrusion molding: The mixture obtained by mixing is sent to the TCJ450 vacuum...

Embodiment 2

[0040] A kind of ancient building restoration blue tiles, the blue tiles are made of the following percentages of raw materials: construction waste 25%, clay 45% and coal gangue 30%; construction waste includes one of waste bricks, waste sand, waste tiles and cement Or more; the steps of the blue tile firing process are as follows:

[0041] Raw material processing: Put construction waste and coal gangue into 4E3216 Lei Meng mill for pulverization, and then use ball mill for ball milling to obtain construction waste powder and coal gangue powder with particle size less than 2 µm;

[0042] Mixing: Transport 45% of clay, 25% of building powder and 30% of coal gangue powder into the planetary mixer for mixing for 1.5 hours. The speed of the mixing plate is controlled to 10.8 rpm, and an appropriate amount of water is added to make the mixture obtained The moisture content is controlled between 17.5%;

[0043] Extrusion molding: The mixture obtained by mixing is sent to the TCJ450 vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com