Aqueous resin composition for flocking and flocked product

A resin composition, water-based technology, applied in the direction of layered products, textiles and papermaking, coating, etc., can solve the problems of viscosity increase, physical property changes, inability to obtain sufficient adhesion, etc., and achieve excellent flocking strength, basic Excellent effect of material adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

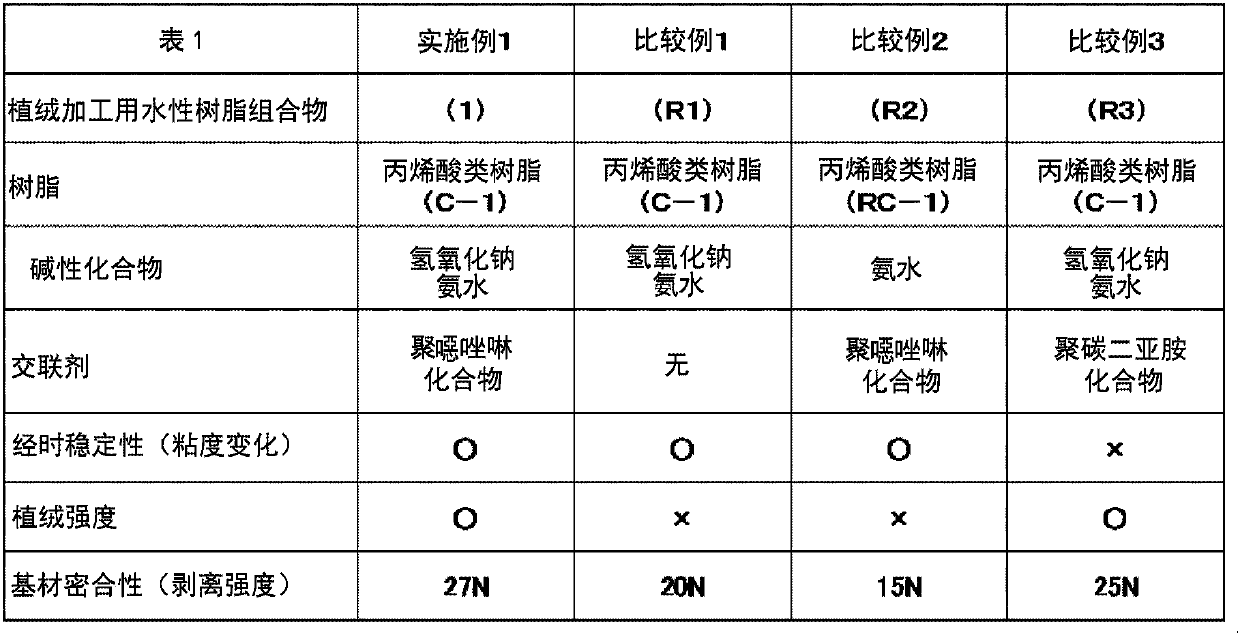

[0042] Next, the present invention will be described more specifically by way of examples and comparative examples.

Synthetic example 1

[0043] (Synthesis Example 1: Synthesis of Acrylic Resin (C-1))

[0044] 3.0 parts by mass of polyoxyethylene alkyl ether sodium sulfate and 263 parts by mass of ion-exchanged water were added to a reaction vessel equipped with a stirrer, a thermometer, a reflux cooler, a nitrogen gas introduction pipe, and a dropping tank, and the temperature was raised to 80°C. While maintaining the temperature, continuously dropwise add 442.5 parts by mass of n-butyl acrylate, 40.0 parts by mass of acrylonitrile, 5.0 parts by mass of methacrylic acid, 5.0 parts by mass of acrylamide, and 2.5 parts by mass of itaconic acid from the dropping tank over 4 hours. , A monomer mixture of 5.0 parts by mass of polyoxyethylene-1-(allyloxymethyl)alkylsulfate ammonium salt and 125 parts by mass of ion-exchanged water. Along with this, the aqueous solution containing 1.3 parts by mass of ammonium persulfate and 5.0 parts by mass of ion-exchanged water was continuously added dropwise over 4 hours. 30 min...

Synthetic example 2

[0045] (Synthesis Example 2: Synthesis of Acrylic Resin (RC-1))

[0046] 18.0 mass parts of 10 mass % sodium hydroxide aqueous solution and 1.5 mass parts of 25 mass % ammonia water used in the synthesis example 1 were changed into 3.0 mass parts of 25 mass % ammonia water, except that it was carried out in the same manner as synthesis example 1 to obtain a non-volatile Aqueous dispersion of acrylic resin (RC-1) with composition 50.0%. Metal hydroxides are not included in the basic compound used as a neutralizing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com