Wavelength-combined laser device

A laser and laser technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve problems such as crosstalk, beam quality and photoelectric conversion efficiency reduction, and achieve high beam quality and high photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

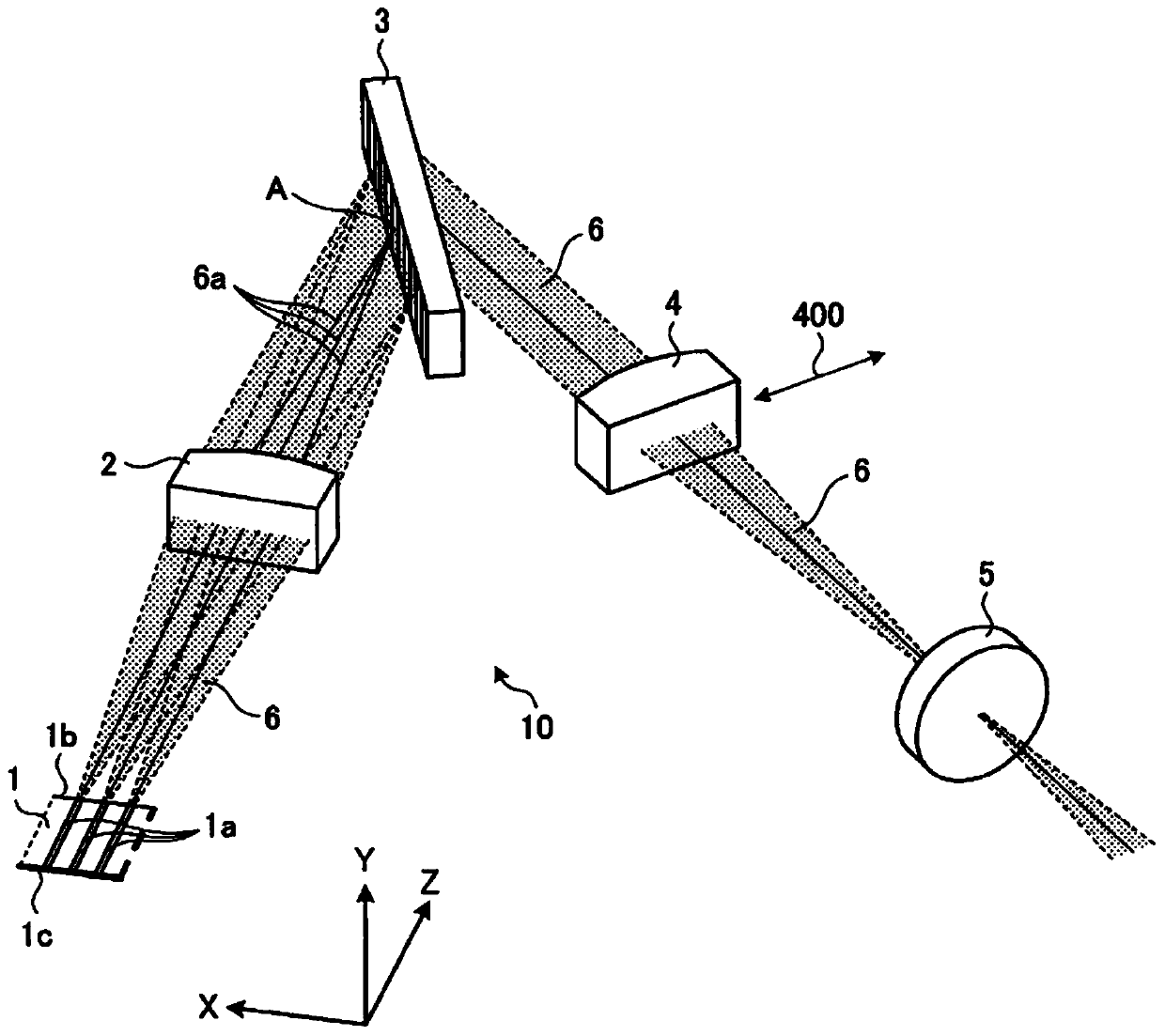

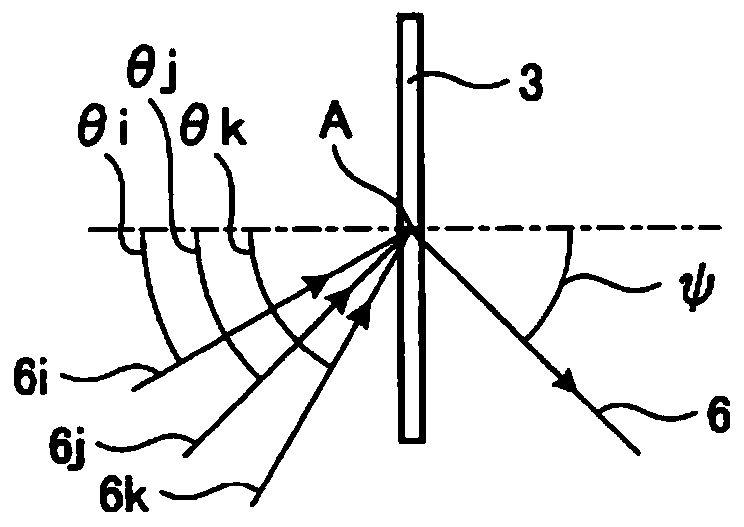

[0030] figure 1 It is a diagram showing the configuration of the wavelength-coupled laser device 10 according to Embodiment 1 of the present invention. The wavelength-coupled laser device 10 has: an LD bar 1 which is a semiconductor laser provided with a plurality of light-emitting portions, ie, a light-emitting layer 1 a ; a light-condensing element 2 ; a wavelength coupling element 3 ; a cross-coupling suppression optical system 4 ; and a partial mirror 5 . A specific example of each of the condensing element 2 and the cross-coupling suppression optical system 4 is a lens. A specific example of the wavelength coupling element 3 is a diffraction grating.

[0031] About 10 to 50 light emitting layers 1 a are provided in the LD bar 1 , and are arranged at equal intervals in the width direction of the LD bar 1 . The width direction of the LD bar 1 is the direction in which the wavelength coupling element 3 couples the laser light 6 , that is, the laser coupling direction. exi...

Embodiment approach 2

[0059] Figure 8 It is a diagram showing the configuration of a wavelength-coupled laser device 11 according to Embodiment 2 of the present invention. exist Figure 8 , labeled with figure 1 and Figure 4 Structural elements with the same reference numbers are the same. The wavelength-coupled laser device 11 shown in the second embodiment includes a beam shaping element 7 . That is, the LD bar 1 of the wavelength-coupled laser device 11 has the beam shaping element 7 facing the output end face 1b. Before the plurality of laser beams 6 emitted as diverging light from the arrayed light emitting layers 1a arranged at equal intervals in the X direction in the width direction of the LD bar 1 coincide with each other, the beam shaping element 7 pairs the laser beams 6 emitted from the LD bar 1 with each other. The laser beam 6 is collimated to suppress the divergence angle. The plurality of laser beams 6 collimated by the beam shaping element 7 enter the wavelength coupling el...

Embodiment approach 3

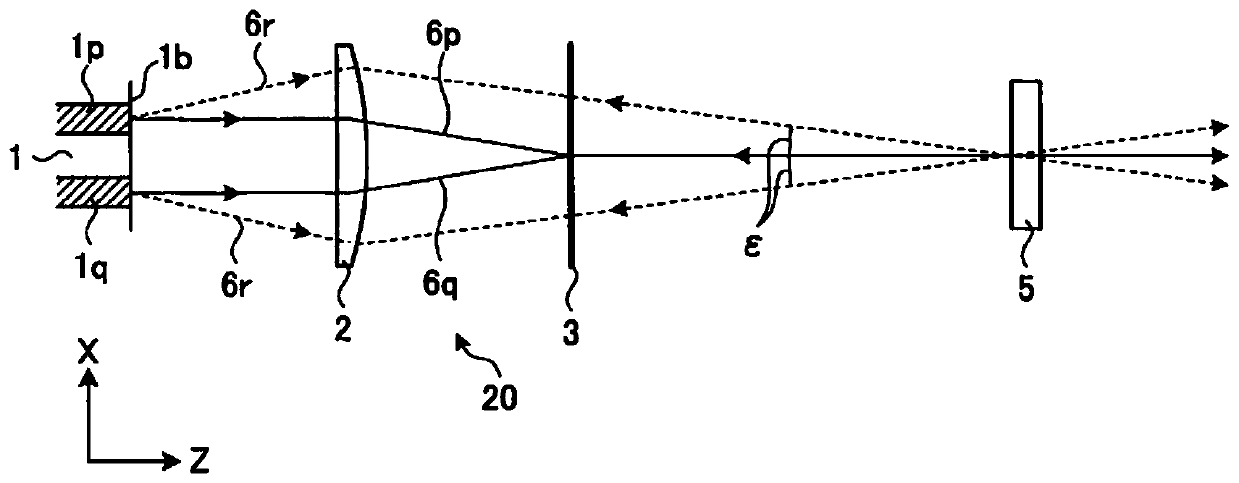

[0070] Figure 11 It is a diagram explaining how the beam quality deteriorates in the wavelength-coupled laser device 10 according to the first embodiment. The cross-coupling oscillation can be suppressed by the cross-coupling suppression optical system 4 included in the wavelength-coupled laser device 10 according to the first embodiment and the wavelength-coupled laser device 11 according to the second embodiment. Lower beam quality degraded.

[0071] Figure 11 It is a diagram for explaining the reduction in beam quality caused by the cross-coupling suppressing optical system 4 in the wavelength-coupled laser device 10 according to the first embodiment. Figure 11 For simplification, only three light emitting layers 1a are drawn. Considering only the laser light 6 emitted from the luminescent layer 1a in the middle, the solid line is the chief ray 6a, and the dotted line is the divergent light representing the imaging of the exit end surface 1b on the partial reflection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com