Efficient insulated cable material and preparation method thereof

A technology for insulating cables and cable materials, which is applied in the field of high-efficiency insulating cable materials and its preparation, which can solve problems such as low safety, poor insulation performance, and easy electric shocks for users, and achieve high safety, improved insulation performance, and improved flame retardancy performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

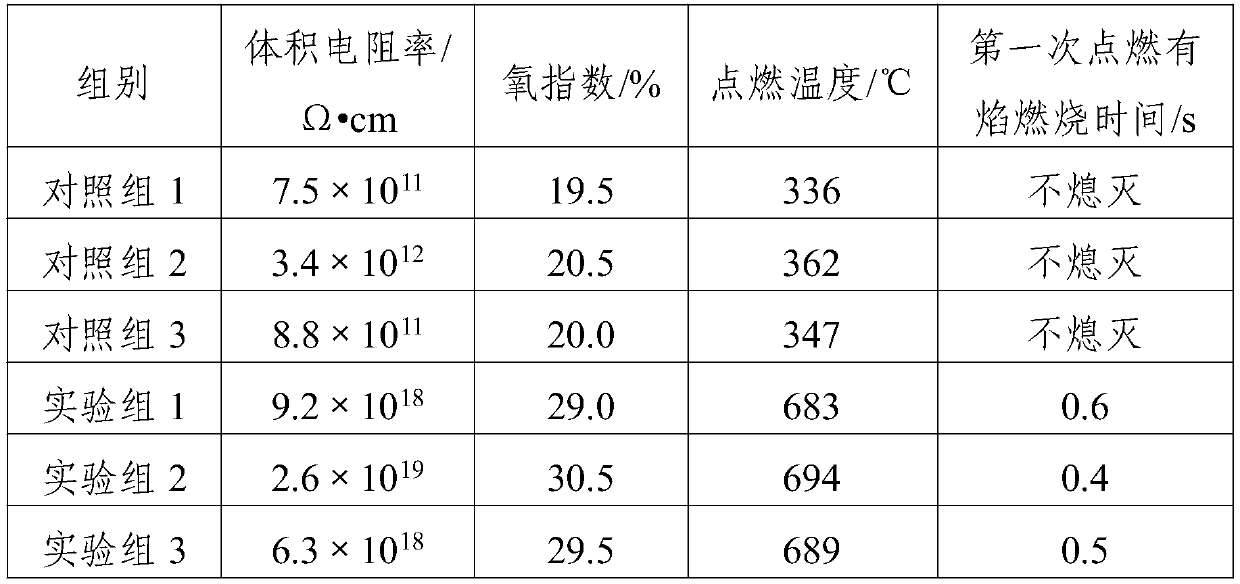

Examples

Embodiment 1

[0026] A high-efficiency insulating cable material, the cable material is made of the following raw materials in parts by weight: 45 parts of EPDM rubber, 15 parts of silicon rubber, 10 parts of polyurethane rubber, 4 parts of phenolic resin, 0.8 parts of polyvinyl chloride, modified 0.5 parts of agent, 5 parts of polyalkylene glycol, 2 parts of polydiphenyl ether, 4 parts of m-xylylenediamine, 3 parts of shellac, 6 parts of sulfur hexafluoride, 3 parts of ammonium phosphate, 5 parts of sulfur, 2 parts of boron nitride, 2 parts of curing agent, 2 parts of vulcanizing agent.

[0027] Wherein, the modifying agent is formed by mixing hexadecyltrimethylammonium bromide and polymethylpyrrolidine with a mass ratio of 2:1; Acid triglycidyl ester and organic acid anhydride are mixed in a mass ratio of 4:3:1; the vulcanizing agent consists of 2-thiol imidazoline, 2,4,6-tris(dimethylaminomethyl)phenol and Cyclohexanone peroxide is mixed in a mass ratio of 5:3:2.

[0028] The preparati...

Embodiment 2

[0036] A high-efficiency insulating cable material, the cable material is made of the following raw materials in parts by weight: 50 parts of EPDM rubber, 18 parts of silicon rubber, 13 parts of polyurethane rubber, 5 parts of phenolic resin, 1.0 part of polyvinyl chloride, modified 0.7 parts of agent, 6 parts of polyalkylene glycol, 3 parts of polydiphenyl ether, 5 parts of m-xylylenediamine, 4 parts of shellac, 7 parts of sulfur hexafluoride, 4 parts of ammonium phosphate, 6 parts of sulfur, 3 parts of boron nitride, 3 parts of curing agent, 3 parts of vulcanizing agent.

[0037] Wherein, the modifying agent is formed by mixing hexadecyltrimethylammonium bromide and polymethylpyrrolidine with a mass ratio of 2:1; Acid triglycidyl ester and organic acid anhydride are mixed in a mass ratio of 4:3:1; the vulcanizing agent consists of 2-thiol imidazoline, 2,4,6-tris(dimethylaminomethyl)phenol and Cyclohexanone peroxide is mixed in a mass ratio of 5:3:2.

[0038] The preparatio...

Embodiment 3

[0046] A high-efficiency insulating cable material, the cable material is made of the following raw materials in parts by weight: 55 parts of EPDM rubber, 20 parts of silicon rubber, 15 parts of polyurethane rubber, 6 parts of phenolic resin, 1.2 parts of polyvinyl chloride, modified 0.8 parts of agent, 7 parts of polyalkylene glycol, 4 parts of polydiphenyl ether, 6 parts of m-xylylenediamine, 5 parts of shellac, 8 parts of sulfur hexafluoride, 5 parts of ammonium phosphate, 7 parts of sulfur, 4 parts of boron nitride, 4 parts of curing agent, 4 parts of vulcanizing agent.

[0047] Wherein, the modifying agent is formed by mixing hexadecyltrimethylammonium bromide and polymethylpyrrolidine with a mass ratio of 2:1; Acid triglycidyl ester and organic acid anhydride are mixed in a mass ratio of 4:3:1; the vulcanizing agent consists of 2-thiol imidazoline, 2,4,6-tris(dimethylaminomethyl)phenol and Cyclohexanone peroxide is mixed in a mass ratio of 5:3:2.

[0048] The preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com