P-type single crystal PERC battery and manufacturing method thereof

A production method and battery technology, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problems that do not conform to the development trend of cost reduction and efficiency improvement in the photovoltaic industry, the decline in the efficiency of batteries and components, and the excess hydrogen atoms of cells, etc., to achieve reduction The content of excess hydrogen atoms, the reduction of production cost, and the effect of reducing excess hydrogen atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

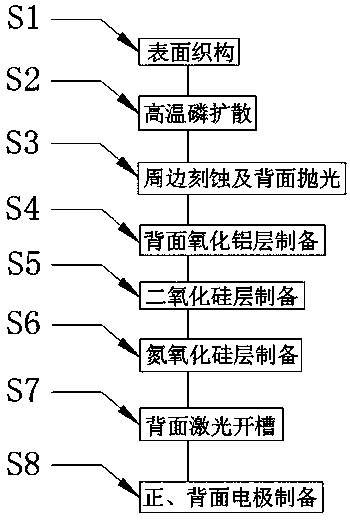

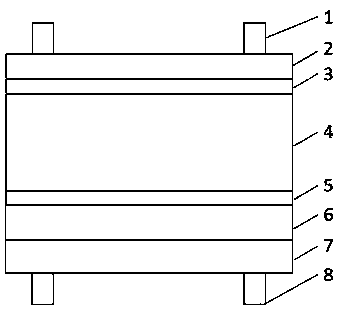

[0035] Step S1, surface texture, also known as alkali texturing, is to use alkali solution to corrode the silicon wafer substrate 4, and form a pyramid-shaped surface morphology on the surface of the silicon wafer substrate 4, wherein, the reaction alkali solution: 1.2wt% NaOH, reaction time: 400s, temperature: 80°C, reflectance after treatment: 11%;

[0036] Step S2, phosphorus diffusion, wherein, nitrogen flow rate: 700sccm, oxygen flow rate: 800sccm, reaction time: 88min, temperature: 800°C, diffusion resistance: 120 ohms; and laser doping method to form a heavily doped region in the front electrode 1 area, Square resistance: 95 ohms;

[0037] Step S3, peripheral etching and back polishing, using 49% HF acid solution to etch the back and edge of the silicon wafer diffused in step S2, and then using 45% KOH and polishing additives to polish the back of the silicon wafer Processing, weight reduction: 0.25g, back reflectivity: 42%;

[0038] Step S4, preparation of the alumin...

Embodiment 2

[0045] Step S1, surface texture, also known as alkali texturing, is to use alkali solution to corrode the silicon wafer substrate 4, and form a pyramid-shaped surface morphology on the surface of the silicon wafer substrate 4, wherein, the reaction alkali solution: 1.2wt% NaOH, reaction time: 400s, temperature: 80°C, reflectance after treatment: 11%;

[0046] Step S2, phosphorus diffusion, wherein, nitrogen flow rate: 700sccm, oxygen flow rate: 800sccm, reaction time: 88min, temperature: 800°C, diffusion resistance: 120 ohms; and laser doping method to form a heavily doped region in the front electrode 1 area, Square resistance: 95 ohms;

[0047] Step S3, peripheral etching and back polishing, using 49% HF acid solution to etch the back and edge of the silicon wafer diffused in step S2, and then using 45% KOH and polishing additives to polish the back of the silicon wafer Processing, weight reduction: 0.25g, back reflectivity: 42%;

[0048] Step S4, preparation of the alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com