Preparation method of nutrient and functional fermented soybean meal fermented by purebred strains

A light tempeh and functional technology, which is applied in the field of preparation of nutrition and functional light tempeh, can solve the problems of harmful bacteria invasion, unfavorable absorption, and long fermentation cycle, so as to improve blood fat-lowering effect, improve digestion utilization rate, and produce The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

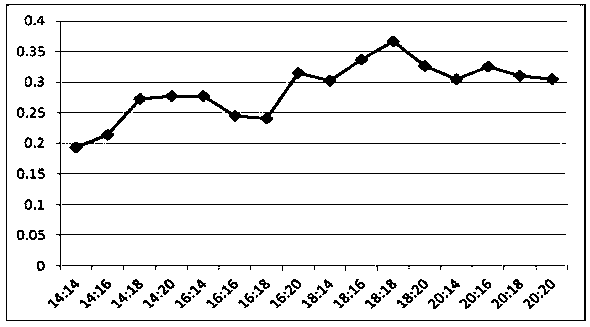

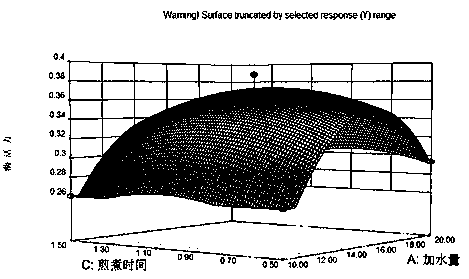

[0036] 1) Pretreatment of raw materials: take selected mulberry leaves and Artemisia annua with a ratio of 14:14, black soybeans 1000g, remove sand and other foreign matter, and then rinse with water. Add 15 times the water to decoct the mulberry leaves and Artemisia annua, decoct twice, 1 hour each time, concentrate the decoction to 500ml, adjust the pH value to 6 with acetic acid, and filter;

[0037] 2) Mixing and sterilizing: mix the water decoction obtained in step 1) into 1000g of clean black soybeans, and after exhaustion, steam in a steamer for 1.5 hours until it is thoroughly steamed and cooled;

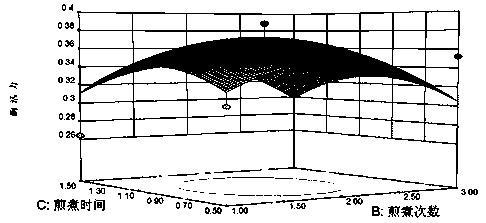

[0038] 3) Fermentation: The mixed material after the sterilization treatment obtained in step 2) is subjected to pure-breed fermentation, and the strain Monascus (Monscus.sp.9901) is inoculated with an inoculum size of 6%, and the fermentation conditions are: the pressure is normal pressure, The humidity is 48-52%, and the temperature is kept at 30-32°C for 28 hours of culti...

Embodiment 2

[0041] 1) Raw material pretreatment: take the selected mulberry leaves and Artemisia annua at a ratio of 18:18, and 1000g of black soybeans, remove foreign matter such as sand and stones, and then rinse with water. Add 15 times the water to decoct the mulberry leaves and Artemisia annua, decoct twice, 1 hour each time, concentrate the decoction to 500ml, adjust the pH value to 6 with acetic acid, and filter;

[0042] 2) Mixing and sterilizing: mix the water decoction obtained in step 1) into 1000g of clean black soybeans, and after exhaustion, steam in a steamer for 1.5 hours until it is thoroughly steamed and cooled;

[0043] 3) Fermentation: The mixed material after the sterilization treatment obtained in step 2) is subjected to pure-breed fermentation, and the strain Monascus (Monscus.sp.9901) is inoculated with an inoculum size of 6%, and the fermentation conditions are: the pressure is normal pressure, The humidity is 48-52%, and the temperature is kept at 30-32°C for 28 ...

Embodiment 3

[0046]1) Raw material pretreatment: Take the selected mulberry leaves and Artemisia annua at a ratio of 20:20, and 1000g of black soybeans, remove foreign matter such as sand and stones, and then rinse with water. Add 15 times the water to decoct the mulberry leaves and Artemisia annua, decoct twice, 1 hour each time, concentrate the decoction to 500ml, adjust the pH value to 6 with acetic acid, and filter;

[0047] 2) Mixing and sterilizing: mix the water decoction obtained in step 1) into 1000g of clean black soybeans, and after exhaustion, steam in a steamer for 1.5 hours until it is thoroughly steamed and cooled;

[0048] 3) Fermentation: The mixed material after the sterilization treatment obtained in step 2) is subjected to pure-breed fermentation, and the strain Monascus (Monscus.sp.9901) is inoculated with an inoculum size of 6%, and the fermentation conditions are: the pressure is normal pressure, The humidity is 48-52%, and the temperature is kept at 30-32°C for 28 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com