Preparation method of sodium butyrate granules and tail gas treatment method thereof

A technology of tail gas treatment and sodium butyrate, which is applied to the method of granulating raw materials, carboxylate preparation, carboxylate preparation, etc., can solve the problems of easy moisture absorption, sour odor, high transportation cost, and easy generation of dust, etc. , to achieve the effect of easy reaction, advanced drying technology, and realization of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

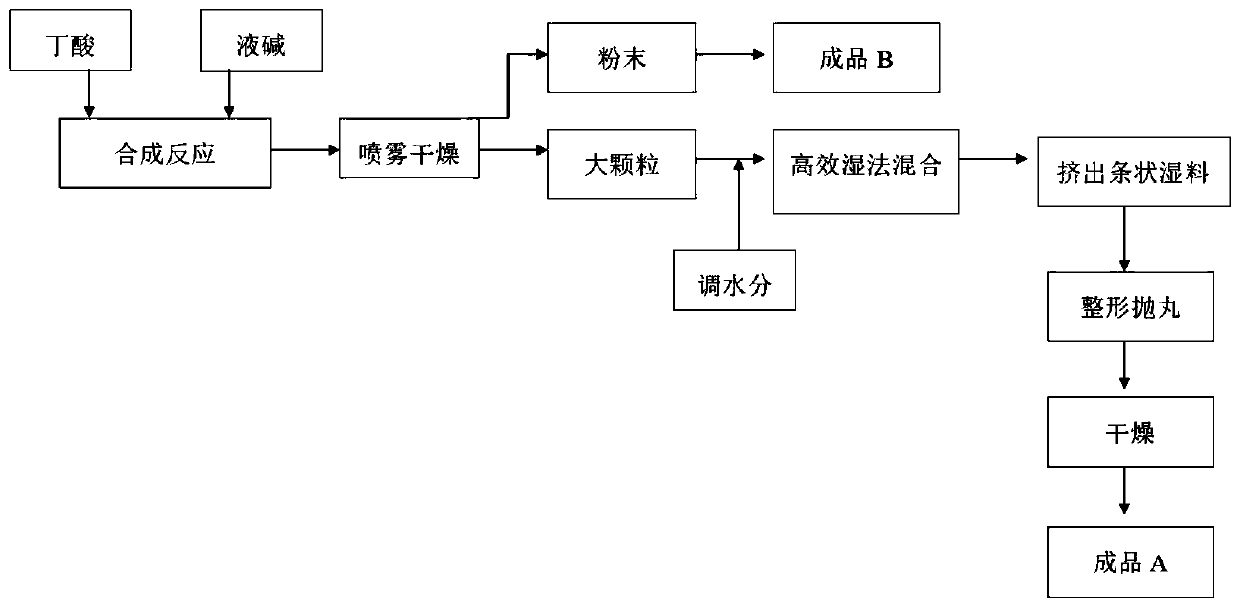

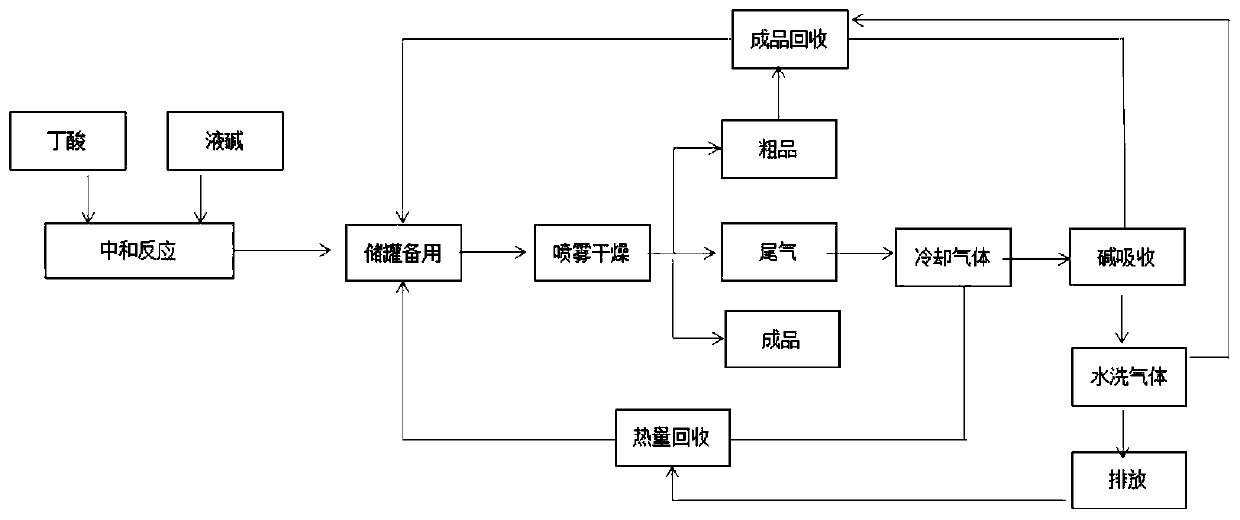

[0036] A kind of sodium butyrate granule preparation method of the present invention and tail gas treatment method thereof are as follows:

[0037] Preparation of S1 sodium butyrate raw material: neutralize n-butyric acid and ionic membrane liquid caustic soda to obtain sodium butyrate reaction liquid, after drying the sodium butyrate reaction liquid through the spray drying system, directly from the bottom of the spray drying system The crude product of sodium butyrate with a water content of 5.5wt% is obtained by flowing out, and the powdery material is collected from the position above the bottom of the spray drying system through the air delivery system, and the finished product is directly packaged;

[0038] S2 mixing: the sodium butyrate crude product with a water content of 5.5 wt% obtained in step S1 is mixed with water, and mixed uniformly by a mixer equipped with a high-speed cutting coulter;

[0039] S3 extruding: the material mixed in step S2 is evenly added into t...

Embodiment 2

[0050] A kind of sodium butyrate granule preparation method of the present invention and tail gas treatment method thereof are as follows:

[0051] Preparation of S1 sodium butyrate raw material: neutralize n-butyric acid and ionic membrane liquid caustic soda to obtain sodium butyrate reaction liquid, after drying the sodium butyrate reaction liquid through the spray drying system, directly from the bottom of the spray drying system The crude product of sodium butyrate with a water content of 3wt% is obtained from the outflow, and the powdery material is collected from the position above the bottom of the spray drying system through the air delivery system, and the finished product is directly packaged;

[0052] S2 mixing: the sodium butyrate crude product with a water content of 3wt% obtained in step S1 is mixed with water, and mixed uniformly by a mixer equipped with a high-speed cutting coulter;

[0053] S3 extruding: the material mixed in step S2 is evenly added into the ...

Embodiment 3

[0064] A kind of sodium butyrate granule preparation method of the present invention and tail gas treatment method thereof are as follows:

[0065] Preparation of S1 sodium butyrate raw material: neutralize n-butyric acid and ionic membrane liquid caustic soda to obtain sodium butyrate reaction liquid, after drying the sodium butyrate reaction liquid through the spray drying system, directly from the bottom of the spray drying system The crude product of sodium butyrate with a water content of 8wt% is obtained by flowing out, and the powdery material is collected from the position above the bottom of the spray drying system through the air delivery system, and the finished product is directly packaged;

[0066] S2 mixing: mixing the sodium butyrate crude product with a water content of 8wt% obtained in step S1 with water, and mixing uniformly with a mixer equipped with a high-speed cutting coulter;

[0067] S3 extruding: the material mixed in step S2 is evenly added into the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com