Luminescent glass for laser lighting and preparation method thereof

A technology of light-emitting glass and laser lighting, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of laser lighting related research and other problems that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The luminescent glass matrix mole percentage that is used for laser illumination of the present embodiment is composed of: B 2 o 3 : 43%, SiO 2 :30%, Na 2 O: 15%, SrO: 12% (i.e., every 100 mol of material in the glass matrix includes 43 mol of B 2 o 3 , 30mol SiO 2 , 15mol of Na 2 O, and 12mol of SrO). Take Na 2 O as an example, the raw material is generally Na 2 CO 3 or Na 2 SiO 3 Etc., other components are also similar, they are all introduced with various stable compounds, and these raw materials will be decomposed into oxides after high-temperature melting.

[0034] CbBr 3 The doping amount of nanocrystals is 0.1% of the amount of borosilicate glass substance, CsPbBr 3 Nanocrystals were obtained by incorporating CsCO 3 , PbBr 2 In situ formation of CsPbBr in the glass after introduction into the glass 3 Perovskite nanocrystals, CsCO 3 and PbBr 2 The molar ratio introduced as raw material was 1:3.3.

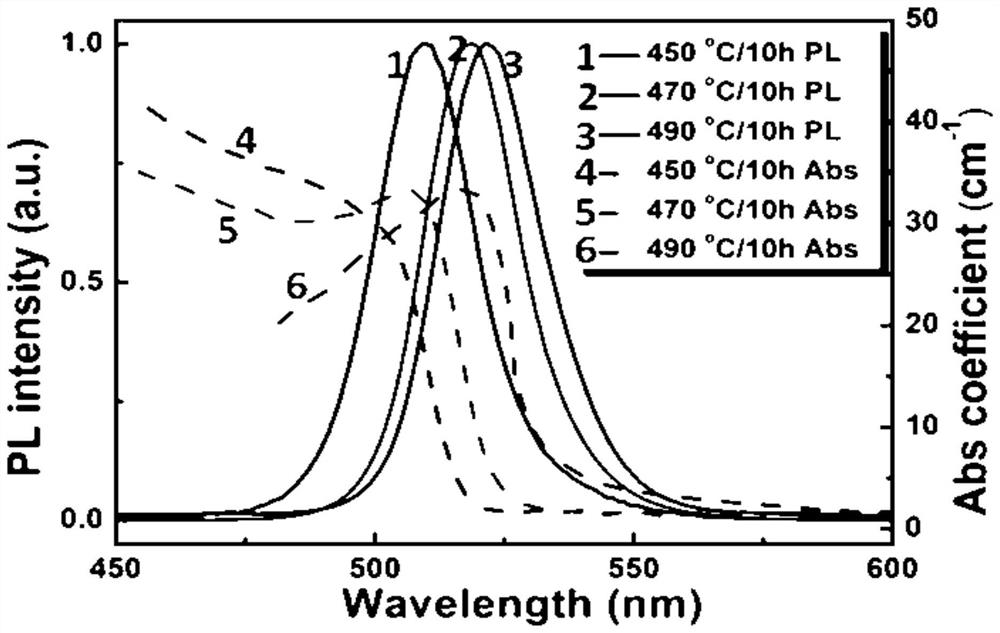

[0035] Weigh each component according to molar ...

Embodiment 2

[0037] The luminescent glass matrix mole percentage that is used for laser illumination of the present embodiment is composed of: B 2 o 3 :50%, SiO2 2 : 20%, Na 2 O: 10%, SrO: 20% (i.e., every 100 mol of material in the glass matrix includes 50 mol of B 2 o 3 , 20mol SiO 2 , 10mol of Na 2 O, and 20mol of SrO), CsPbI 3 The doping amount of nanocrystals is 5% of the amount of borosilicate glass substance, CsPbI 3 Nanocrystals were obtained by incorporating CsCO 3 , PbI 2 In situ formation of CsPbI in the glass after introduction into the glass 3 Perovskite nanocrystals, CsCO 3 and PbI 2 The molar ratio introduced as raw material was 1:4. Weigh each component according to the mole percentage, mix them evenly, put them in a crucible, keep them warm at 1100°C for 20 minutes, pour the glass melt into a mold and anneal at 350°C for 2 hours, the heat treatment system is 460°C, 480°C ℃, 500℃ heat treatment for 10h, its absorption and fluorescence spectra are as follows F...

Embodiment 3

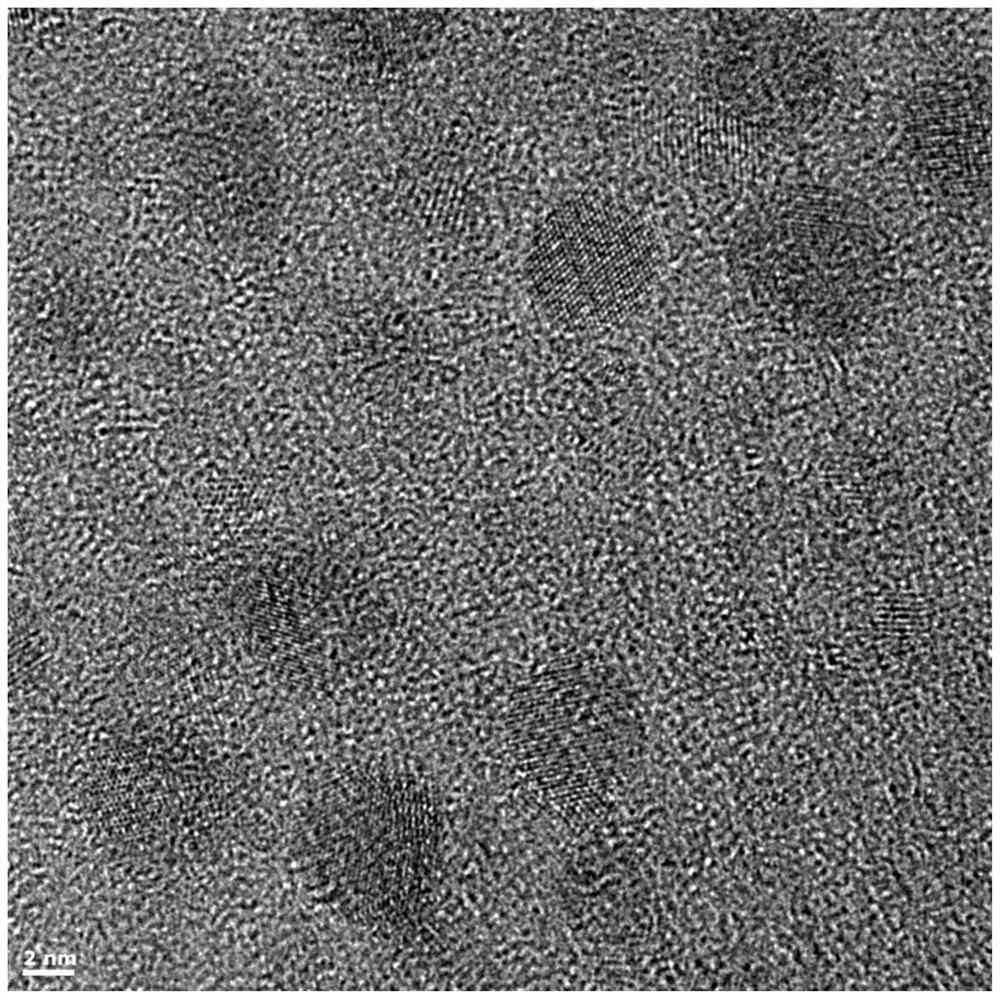

[0039] The luminescent glass matrix mole percentage that is used for laser illumination of the present embodiment is composed of: B 2 o 3 :40%, SiO 2 :27%, Na 2 O: 15%, SrO: 18% (i.e., every 100 mol of material in the glass matrix includes 40 mol of B 2 o 3 , 27mol of SiO 2 , 15mol of Na 2 O, and 18mol of SrO), CsPbBr 3 The doping amount of nanocrystals is 0.3% of the amount of borosilicate glass substance, CsPbBr 3 Nanocrystals were obtained by incorporating CsCO 3 , PbBr 2 In situ formation of CsPbBr in the glass after introduction into the glass 3 Perovskite nanocrystals, CsCO 3 and PbBr 2 The molar ratio introduced as raw material was 1:3.3. Weigh each component according to the molar percentage, mix them evenly, put them in a crucible, and keep them warm at 1050°C for 30 minutes, pour the glass melt into the mold and anneal at 350°C for 2 hours, and the heat treatment system is heat treatment at 400°C for 20 hours , whose fluorescence spectrum is as Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com