Graphene ceramic-bustion composite energy-saving material as well as preparation method and application thereof

An energy-saving material and composite material technology, applied in the field of graphene porcelain moxibustion composite energy-saving material and its preparation, can solve the problems of inconvenience of health store operators, slow temperature raising of grooved beds, large operating costs, etc., to achieve a good physical therapy experience, enhance The effect of increasing the temperature and enhancing the heat storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

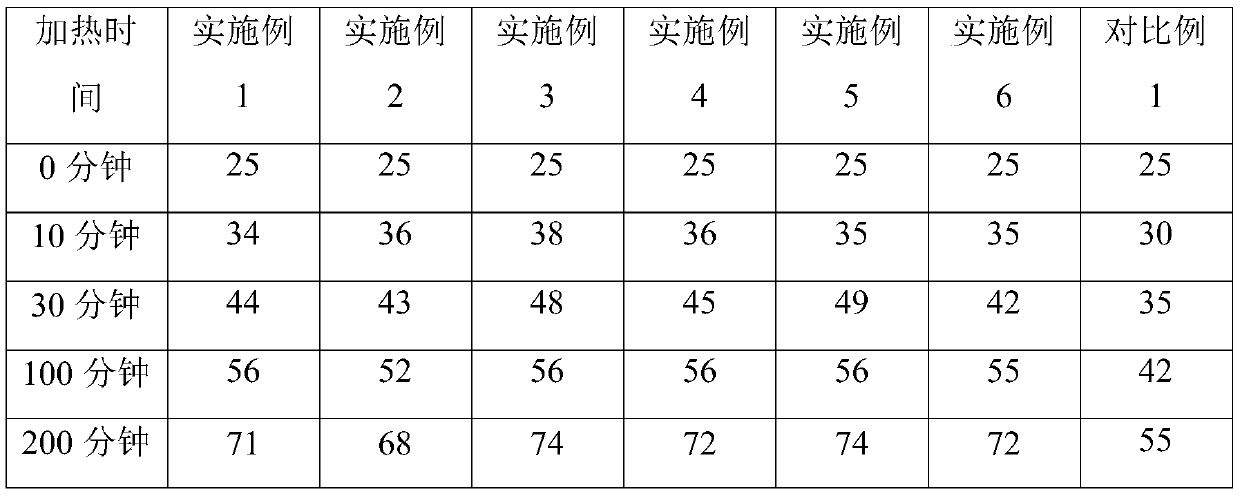

Examples

Embodiment 1-6

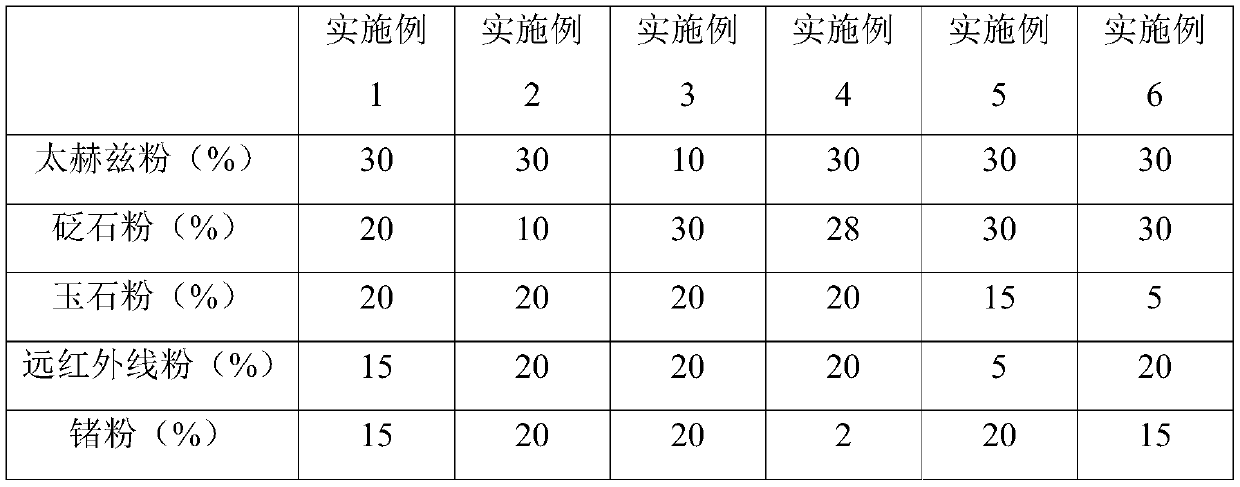

[0042] The raw material composition of the graphene porcelain moxibustion composite energy-saving material is shown in Table 1.

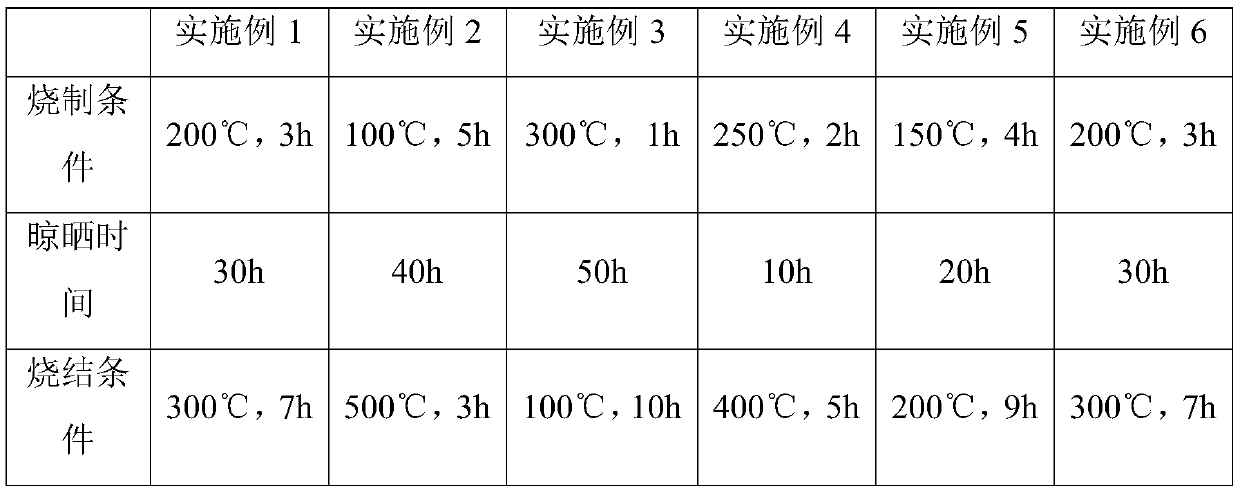

[0043] The raw material composition of the heat storage materials used is shown in Table 2.

[0044] The raw material composition of the high-frequency materials used is shown in Table 3.

[0045] The raw material composition of the antibacterial materials used is shown in Table 4.

[0046] The pore-forming material is activated carbon powder.

[0047] The binding material is sodium metasilicate.

[0048] The preparation method consists of the following steps:

[0049] 1) First, mix kaolin, sepiolite and alumina, and grind to a particle size of 100-500 mesh to obtain composite material A;

[0050] 2) Mix graphene with composite material A, bake at 100-300°C for 1-5 hours, and grind to a particle size of 50-500 mesh to prepare composite material B;

[0051] 3) Mix the high-frequency material with the antibacterial material, and grind it to a particle size of 100-5...

Embodiment 1

[0086] The power consumption of the material of Example 1 is 25.6 degrees.

[0087] The power consumption of the material of Comparative Example 1 was 32.7 degrees.

[0088] In summary, it can be seen that the material of Example 1 saves more than 20% of electricity compared with the material of Comparative Example 1.

[0089] 5. About antibacterial and antibacterial properties

[0090] The bacteriostatic rate of the material of Example 1 against Escherichia coli was 99.6% and the bacteriostatic rate against Staphylococcus aureus was 99.4%.

Embodiment 2

[0091] The bacteriostatic rate of the material of Example 2 against Escherichia coli was 99.7%, and the bacteriostatic rate against Staphylococcus aureus was 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com