Preparation method of graphene interface modified carbon fiber/epoxy resin composite

A technology of epoxy resin and composite materials, which is applied in the field of chemistry and chemical engineering, can solve problems in the initial stage and achieve the effects of easy operation, simple improvement process, and improved interface load transfer capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment provides a kind of method of graphene interface modification carbon fiber / epoxy resin composite material, comprises the following steps:

[0028] S1. Preparation of graphene slurry: fully disperse 0.05g of graphene into 50g of absolute ethanol, and then disperse by ultrasonic for 4h to obtain a graphene slurry with a mass fraction of 0.1%.

[0029] S2. Interface modification: Cut the carbon fiber cloth into a size of 15cm*10cm, then completely soak it in the graphene slurry obtained in S1, and dry it at 80°C for 4 hours after 30 minutes;

[0030] S3, preparation of epoxy resin mixture: take 50g epoxy resin, 20g curing agent and 0.15g defoamer, first adopt the mode of mechanical stirring to mix the three for 40min, then ultrasonic 10min to remove air bubbles, and further mix uniformly to obtain mixture;

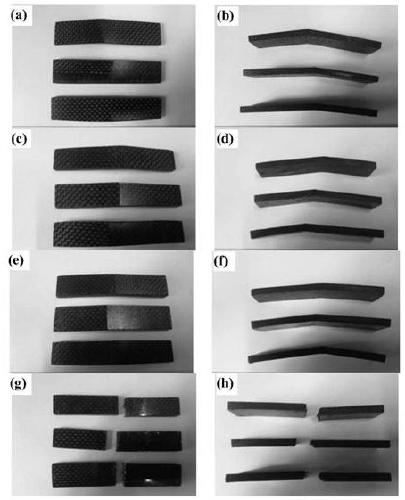

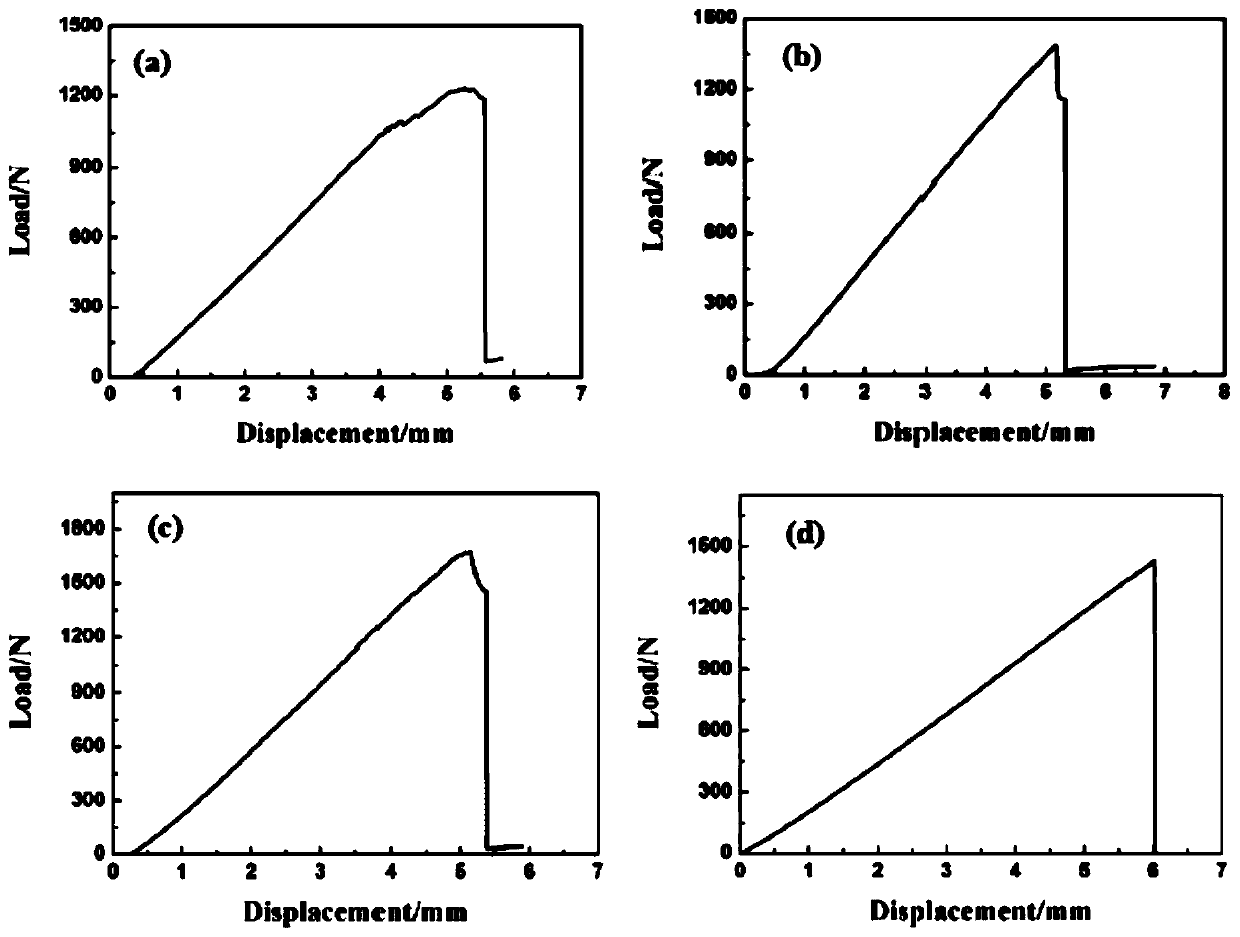

[0031] S4. Lamination: Immerse the carbon fiber cloth modified by the interface of S2 in the mixture obtained in S3 for 6 minutes, place the ful...

Embodiment 2

[0034] The present embodiment provides a kind of method of graphene interface modification carbon fiber / epoxy resin composite material, comprises the following steps:

[0035] S1. Preparation of graphene slurry: fully disperse 0.15g of graphene into 50g of absolute ethanol, and then disperse by ultrasonic for 5h to obtain a graphene slurry with a mass fraction of 0.3%;

[0036] S2. Interface modification: Cut the carbon fiber cloth into a size of 15cm*10cm, then completely soak it in the graphene slurry obtained in S1, and dry it at 50°C for 5h after 30min;

[0037] S3, preparation of epoxy resin mixture: take 50g epoxy resin, 15g curing agent and 0.10g defoamer, first adopt the mode of mechanical stirring to mix the three for 30min, then ultrasonic 20min to remove air bubbles, and further mix evenly to obtain mixture;

[0038] S4. Lamination: Immerse the carbon fiber cloth modified by the interface of S2 in the mixture obtained in S3 for 7 minutes, place the fully impregnate...

Embodiment 3

[0041] The present embodiment provides a kind of method of graphene interface modification carbon fiber / epoxy resin composite material, comprises the following steps:

[0042] S1. Preparation of graphene slurry: fully disperse 0.3g of graphene into 50g of absolute ethanol, and then disperse by ultrasonic for 6h to obtain a graphene slurry with a mass fraction of 0.6%;

[0043] S2. Interface modification: Cut the carbon fiber cloth into a size of 15cm*10cm, then completely soak it in the graphene slurry obtained in S1, and dry it at 100°C for 3 hours after 30 minutes;

[0044] S3, preparation of epoxy resin mixture: take 50g epoxy resin, 25g curing agent and 0.25g defoamer, first adopt the mode of mechanical stirring to mix the three for 20min, then ultrasonic 30min to remove air bubbles, and further mix evenly to obtain mixture;

[0045] S4. Lamination: Immerse the carbon fiber cloth modified by the interface of S2 in the mixture obtained in S3 for 7 minutes, place the fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com