A high-temperature straw-degrading bacterium b-8 and its agent and application

A technology of straw and bacteria, applied in the field of agricultural resources and environment, to achieve the effect of accelerating the return of field to decompose, broad application prospects and promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

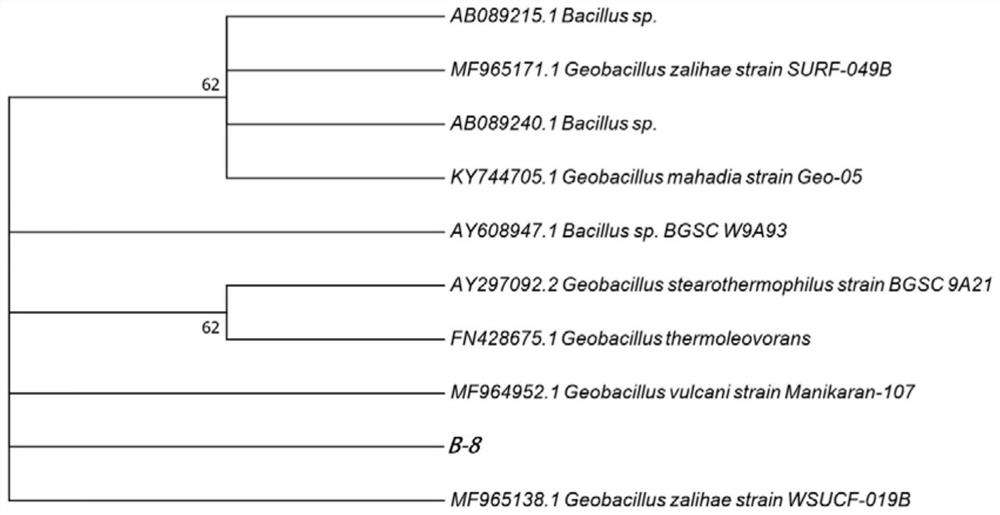

[0030] Isolation and Identification of Straw Degrading Bacteria B-8

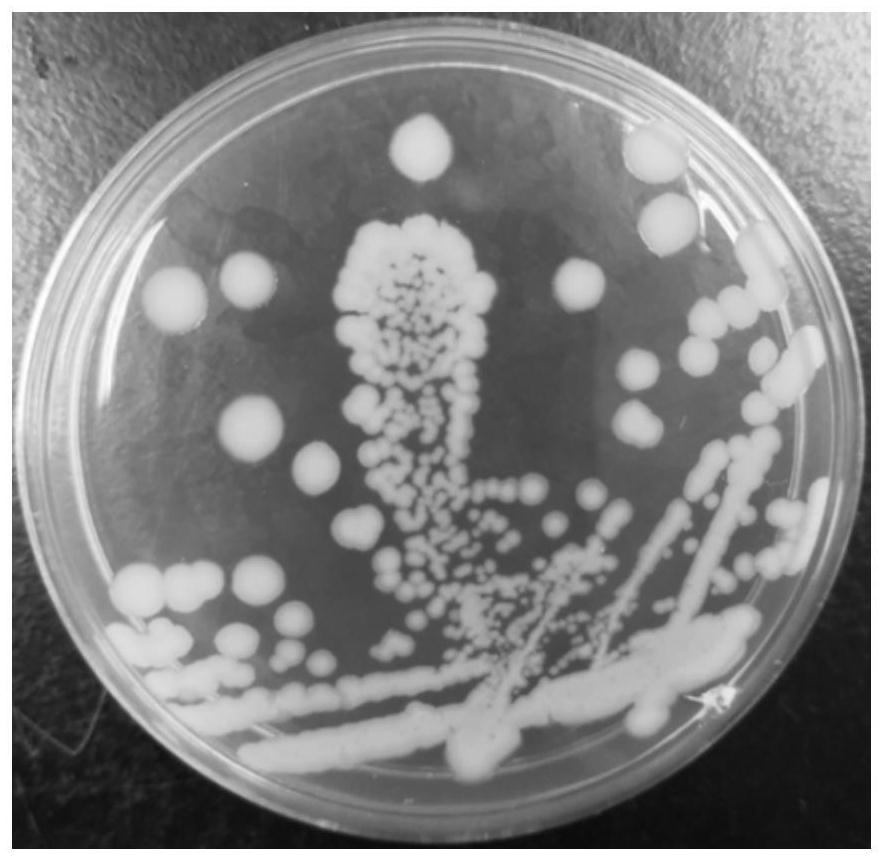

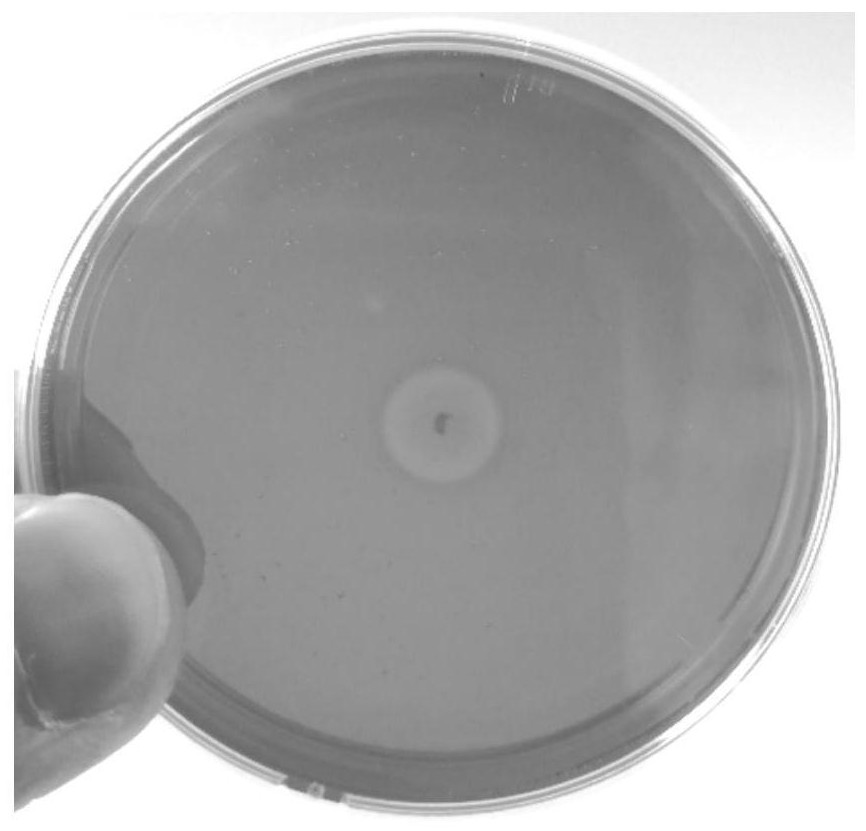

[0031] The straw-degrading bacterial strain B-8 was screened from a straw accumulation place in Weifang City, Shandong Province. Apply the serially diluted sample suspension to the CMC-Congo red medium plate by using the gradient dilution coating method, and cultivate and screen the cellulose-degrading bacteria at 75°C. Purify and isolate the strains that produce larger transparent circles and grow faster on the CMC-Congo red medium plate, inoculate them on the rice straw medium with rice straw as the only carbon source, culture at 75°C, and compare the growth of each strain The bacterial strain B-8, which can efficiently degrade rice straw under high temperature conditions, was finally obtained.

[0032] CMC-Congo red medium: sodium carboxymethylcellulose (CMC-Na) 10.0g, (NH 4 ) 2 SO 4 2.0g, KH 2 PO 4 1.0g, MgSO 4 ·7H 2 O 0.5g, Congo red 0.2g, agar 20g, deionized water 1000mL, pH natural, autoclave...

Embodiment 2

[0038] Inoculate the strain B-8 into the NB medium, and cultivate it at a temperature of 75°C and a rotation speed of 170r / m for 8-12 hours to the logarithmic phase; then inoculate the bacteria B-8 cultivated to the logarithmic phase at an inoculation amount of 1%. Inoculate in rice straw liquid culture medium, cultivate for 7 days at a temperature of 75°C and a rotational speed of 170r / m, remove bacteria and impurities by centrifugal filtration, obtain a crude enzyme solution, and determine endonuclease and β-glucosidase in the crude enzyme solution , xylanase, β-xylosidase activity, see Table 1.

[0039] Rice straw liquid medium: rice straw powder 20g, (NH 4 ) 2 SO 4 1.4g, KH 2 PO 4 2g, MgSO 4 ·7H 2 O0.3g, CaCl 2 2H 2 O 0.4 g, tryptone 1 g, FeSO 4 ·7H 2 O 0.0075g, MnSO 4 ·H 2 O 0.0025g, ZnSO 4 0.002g, CoCl 2 0.003g, 1000mL of deionized water, natural pH, autoclaved at 121°C for 20 minutes; wherein, the rice straw powder is obtained by drying the rice straw to...

Embodiment 3

[0044] Using the method of liquid fermentation in a triangular flask to study the degradation effect of bacteria B-8 on rice straw:

[0045] Preparation of bacterial agent: inoculate strain B-8 into NB culture medium, and cultivate at 75°C and 170r / m for 8-12h to logarithmic phase; then culture B-8 to logarithmic phase 1% inoculum amount was inoculated in rice straw liquid culture medium, cultured for 7 days under the conditions of temperature 75° C. and rotation speed 170 r / m, and centrifugal filtration to remove bacteria and impurities to obtain bacterial agent.

[0046] Pretreatment of rice straw: Soak rice straw in 1% NaOH solution for 30 minutes to remove the wax on the surface of the straw, so that cellulolytic bacteria can better contact with the cellulose in the straw, dry at 50°C, and shred to 2-3cm long.

[0047] Liquid enzyme production medium: (NH 4 ) 2 SO 4 1.4g, KH 2 PO 4 2g, MgSO 4 ·7H 2 O 0.3g, CaCl 2 2H 2 O0.4g, tryptone 1g, FeSO 4 ·7H 2 O 0.0075g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com