Preparation process of titanium-zirconium alloy applied to tooth root implant

An implant and titanium zirconium technology is applied in the field of preparation of stomatological materials, which can solve the problems of material performance decline, poor alloy uniformity, and high cost of compression molding, and achieve the effects of low impurity element content, high strength and uniform tissue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

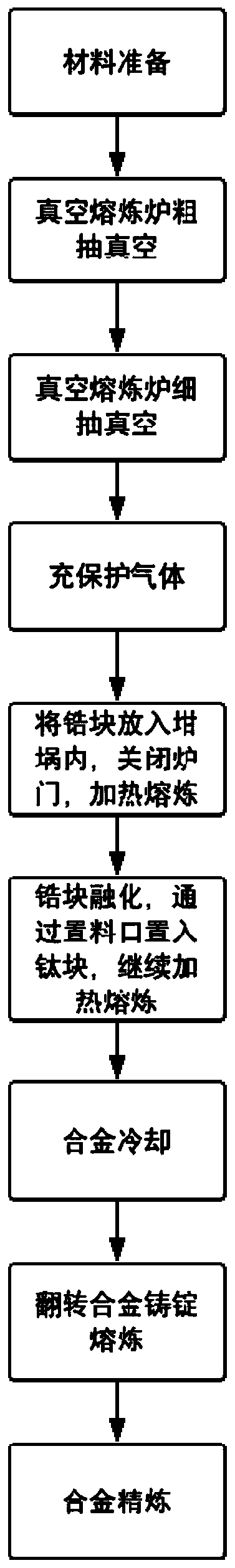

[0022] combine figure 1 , a method for preparing a titanium-zirconium alloy applied to a tooth root implant, the preparation steps are as follows:

[0023] Step 1, material preparation: remove the oxide scale layer of the titanium block and the zirconium block, and use an ultrasonic cleaning machine to clean the titanium block and the zirconium block; wherein the purity of the titanium block and the zirconium block is higher than 99.5% (wt%), and the titanium The mass percentage ranges of block and zirconium block are as follows: titanium block 85%-50% (wt%), zirconium block 15%-50% (wt%).

[0024] Step 2. Melting preparation: clean the vacuum suspension melting furnace, wipe the crucible with alcohol, place the zirconium block evenly in the crucible, and close the furnace door of the vacuum suspension melting furnace;

[0025] Step 3. Vacuumize the vacuum suspension melting furnace: first, rough vacuum the vacuum suspension melting furnace to a vacuum degree of 10 Pa, and fi...

Embodiment 1

[0032] combine figure 1 , the preparation method of the titanium-zirconium alloy applied to the root implant of the present invention, the steps are as follows:

[0033] Step 1. Preparation before smelting: mix titanium block and zirconium block with a total mass of 7kg and a mass ratio of 17:3 with a purity of 99.5%, and remove the oxide layer on it with a file or sandpaper. Ultrasonic cleaner to clean and allow to dry.

[0034] Step 2. Clean up the impurities in the furnace and the crucible of the vacuum suspension melting furnace, and clean the impurities in the crucible of the vacuum suspension melting furnace with alcohol. Place the zirconium blocks evenly in the crucible, and close the furnace door.

[0035] Step 3. Vacuuming the vacuum suspension melting furnace: first perform rough vacuuming, open the mechanical pump waterway and molecular pump waterway switch of the vacuum suspension melting furnace, and open the argon gas valve in order to discharge the air from th...

Embodiment 2

[0044]Step 1. Preparation before smelting: use pure zirconium and pure titanium with a purity of 99.5% as raw materials, mix according to a total mass of 7kg, and a mass ratio of pure titanium to pure zirconium of 6:4, clean with alcohol, and make it dry.

[0045] Step 2. Clean the melting furnace of the vacuum suspension melting furnace and the crucible of the vacuum suspension melting furnace, place pure zirconium evenly in the crucible of the vacuum suspension melting furnace, and close the furnace door of the vacuum suspension melting furnace.

[0046] Step 3. Vacuuming the vacuum suspension melting furnace: first perform rough vacuuming, open the mechanical pump waterway and molecular pump waterway switch of the vacuum suspension melting furnace, and open the argon gas valve in order to discharge the air from the air pipe connecting the argon tank and the vacuum suspension melting furnace , open the pressure reducing valve to 0.5Mpa, charge for about 7 seconds. Turn on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com