Environmentally-friendly high-performance aqueous alkyd resin preparation method

A water-based alkyd resin and alkyd resin technology, applied in the field of coatings, can solve the problems of water-based alkyd resin performance degradation, secondary pollution of the environment, insignificant flame retardancy, etc., to increase adhesion, prevent secondary pollution, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

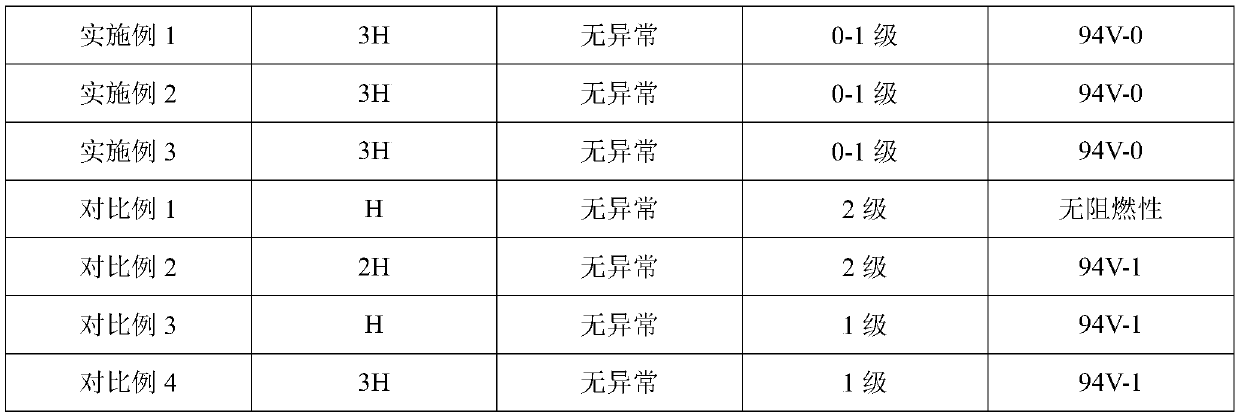

Embodiment 1

[0035] Embodiment 1: a kind of preparation method of environment-friendly high-performance water-based alkyd resin comprises the following preparation steps:

[0036] 1) Mix 20 parts of soy oil, 40 parts of epoxy resin and 0.1 part of triphenylphosphine, protect with nitrogen, stir and react at 110°C for 2 hours to obtain epoxy ester;

[0037] 2) Mix 30 parts of soy oleic acid, 12 parts of isophthalic anhydride, 13 parts of maleic anhydride, 20 parts of trimethylolpropane, 0.1 part of dibutyltin dilaurate and 15 parts of xylene, at 180°C Stir and react under low temperature, keep it warm for 1 hour, then raise the temperature to 240°C, and keep warm for 1 hour for esterification, until the acid value is lower than 20mgKOH / g, and the alkyd resin is obtained;

[0038] 3) Mix 30 parts of epoxy ester, 100 parts of alkyd resin, 2 parts of dibutyltin dilaurate and 10 parts of xylene, stir and react at 150°C, keep warm for 1.5h until the acid value is lower than 10mgKOH / g, Obtain ep...

Embodiment 2

[0043] Embodiment 2: a kind of preparation method of environment-friendly high-performance water-based alkyd resin comprises the following preparation steps:

[0044] 1) Mix 50 parts of ricinoleic acid, 25 parts of epoxy resin and 0.5 part of triphenylphosphine, protect with nitrogen, stir and react at 130°C for 1.2h to obtain epoxy ester;

[0045] 2) Mix 60 parts of ricinoleic acid, 4 parts of phthalic anhydride, 6 parts of isophthalic anhydride, 35 parts of pentaerythritol, 0.3 parts of dibutyltin dilaurate and 13 parts of xylene, and stir the reaction at 150°C , keep warm for 2 hours, then raise the temperature to 230°C, and keep warm for 2 hours until the acid value is lower than 20mgKOH / g to obtain alkyd resin;

[0046] 3) Mix 20 parts of epoxy ester, 120 parts of alkyd resin, 1 part of dibutyltin dilaurate and 20 parts of xylene, stir and react at 160°C, keep it warm for 1h until the acid value is lower than 10mgKOH / g, and get Epoxy ester modified alkyd resin;

[0047]...

Embodiment 3

[0051] Embodiment 3: a kind of preparation method of environment-friendly high-performance water-based alkyd resin comprises the following preparation steps:

[0052] 1) Mix 35 parts of linoleic acid, 55 parts of epoxy resin and 1 part of triphenylphosphine, protect with nitrogen, stir and react at 150°C for 0.5h to obtain epoxy ester;

[0053] 2) Mix 45 parts of linoleic acid, 18 parts of phthalic anhydride, 22 parts of maleic anhydride, 50 parts of ethylene glycol, 0.5 parts of dibutyltin dilaurate and 10 parts of xylene, and mix them at 165°C Stir the reaction, keep it warm for 1.5h, then raise the temperature to 220°C, and keep warm for 3h for esterification, until the acid value is lower than 20mgKOH / g, and the alkyd resin is obtained;

[0054] 3) Mix 25 parts of epoxy ester, 130 parts of alkyd resin, 3 parts of dibutyltin dilaurate and 25 parts of xylene, stir and react at 170°C, keep warm for 0.5h until the acid value is lower than 10mgKOH / g, Obtain epoxy ester modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com