A kind of lignin-starch combined masterbatch composite biodegradable polyester material and preparation method thereof

A technology of biodegradable polyester and polyester degradation, which is applied in the field of biodegradable polyester materials and its preparation, can solve problems such as poor interface compatibility, achieve good light-blocking properties, low light transmittance, and prevent regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

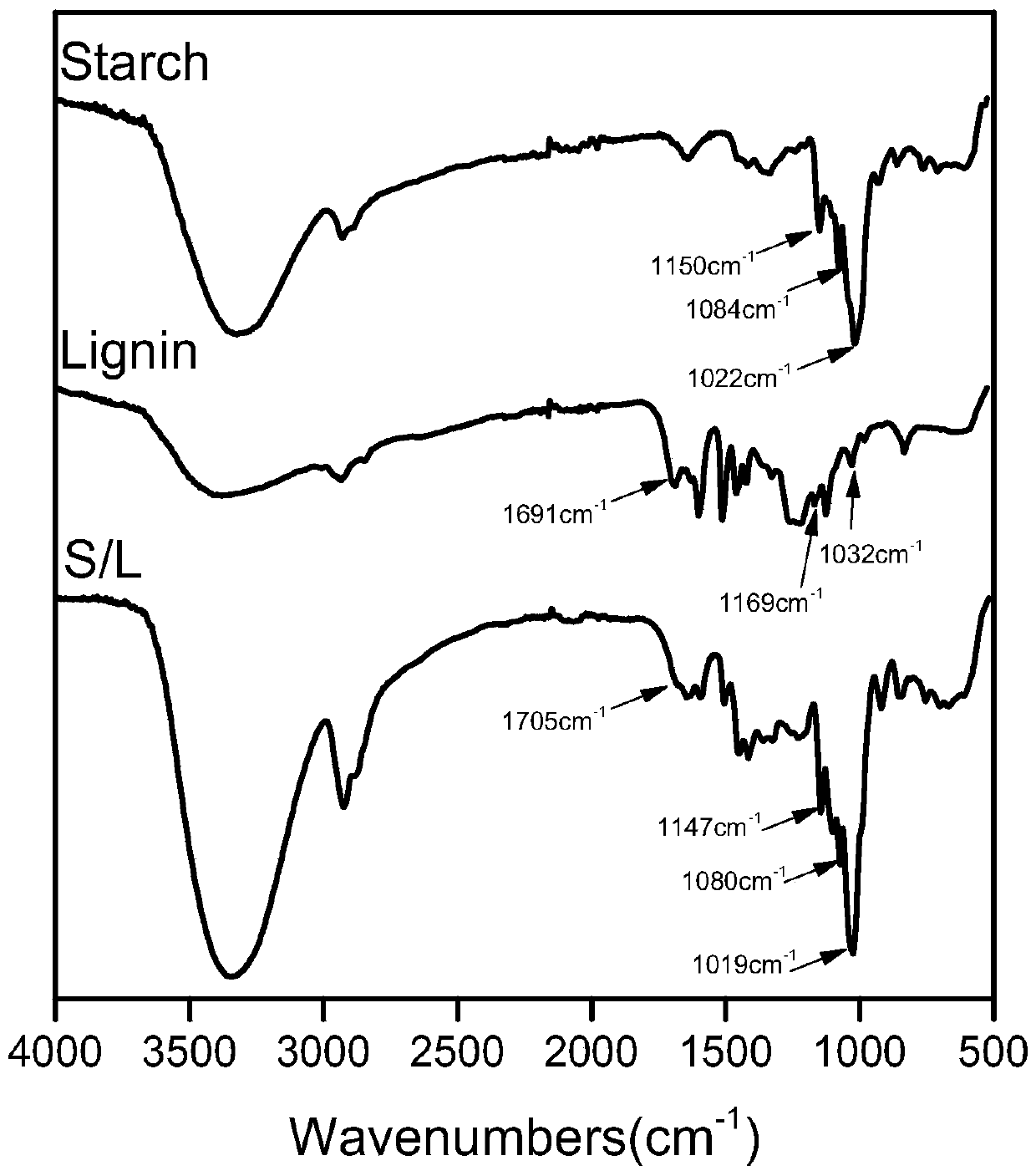

Method used

Image

Examples

Embodiment 1

[0035] The lignin, starch and polybutylene terephthalate-adipate were vacuum-dried at 85° C. for 6 hours. Take 35 parts of organic solvent lignin, 50 parts of corn starch, 2 parts of ethylene bis stearic acid amide and 15 parts of ethylene glycol and fully mix them in a high-speed mixer at a speed of 900 rpm and a mixing time of 5 minutes to obtain a premix ; Melt and extrude the premixed material through a twin-screw extruder to obtain a combined masterbatch, and the temperature of the twin-screw extruder is set at 140-180°C; Butylene glycol ester is melt-extruded and granulated at 140-180°C by a twin-screw extruder to obtain composite particles; the composite particles are blown into film / injection molded strips at a temperature of 140-180°C.

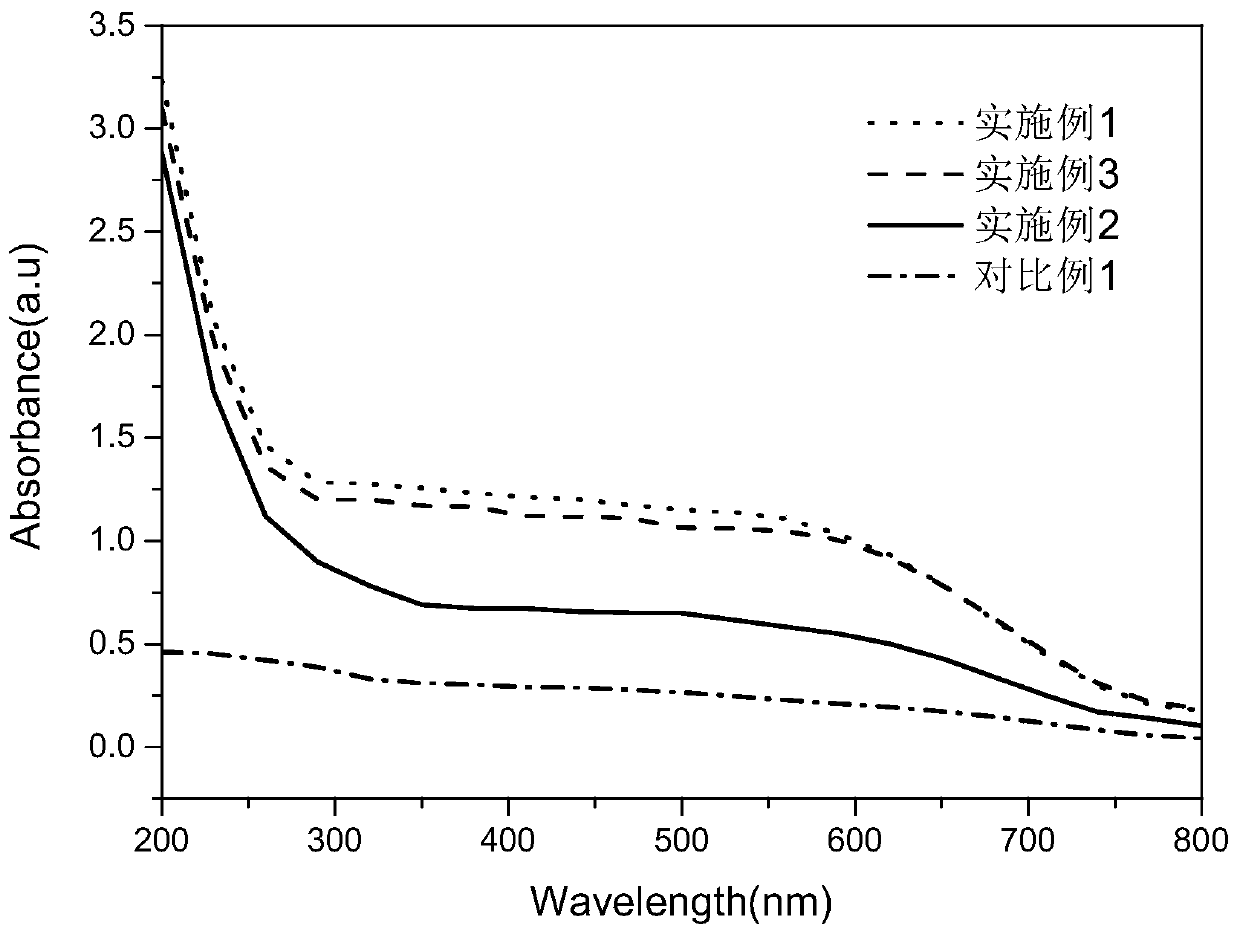

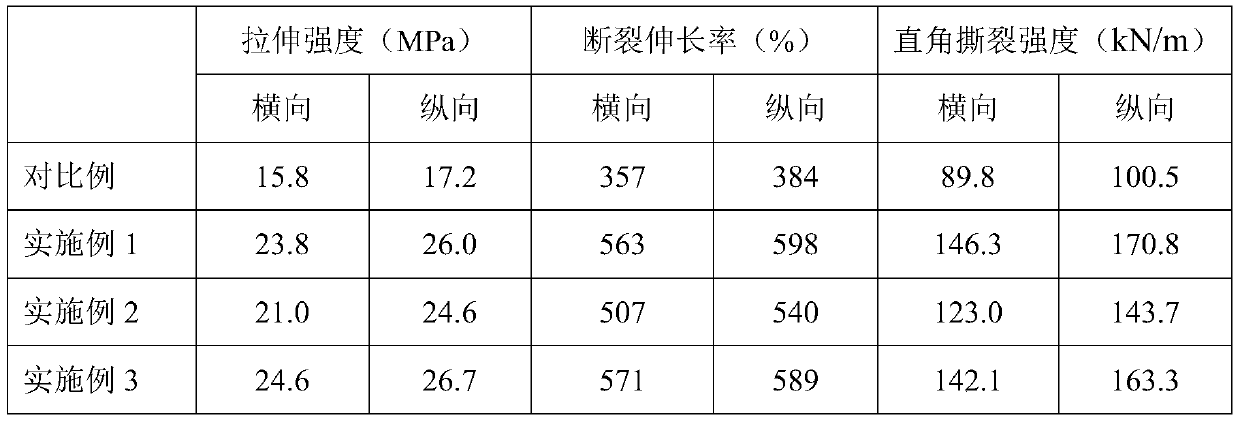

[0036] The tensile strength, elongation at break, right-angle tear strength and absorbance of the degradable film that embodiment 1 obtains are tested, and test data is as table 1 and figure 1 shown.

[0037] The tensile strength, e...

Embodiment 2

[0039] The lignin, starch and polybutylene terephthalate-adipate were vacuum-dried at 85° C. for 6 hours. Get 20 parts of kraft lignin, 60 parts of potato starch, 2 parts of butyl stearate and 20 parts of glycerin and fully mix them in a high-speed mixer with a rotating speed of 900 rpm and a mixing time of 5 minutes to obtain a premix; The material is melt-extruded through a twin-screw extruder to obtain a combined masterbatch, and the temperature of the twin-screw extruder is set at 140-180°C; the obtained combined masterbatch is compounded with 60 parts of polybutylene terephthalate-adipate The ester is melt-extruded and granulated by a twin-screw extruder at 140-180°C to obtain composite particles; the composite particles are blown into film / injection molded strips at a temperature of 140-180°C.

[0040] The tensile strength, elongation at break, right-angle tear strength and absorbance of the degradable film that embodiment 2 obtains are tested, and test data is as table ...

Embodiment 3

[0043] The lignin, starch and polybutylene succinate-adipate were vacuum-dried at 85° C. for 6 hours. Get 15 parts of alkali-extracted lignin, 60 parts of tapioca starch, 2 parts of butyl stearate and 25 parts of glycerin and fully mix them in a high-speed mixer with a rotating speed of 900 rpm and a mixing time of 5 minutes to obtain a premix; The mixture is melted and extruded by a twin-screw extruder to obtain a combined masterbatch, and the temperature of the twin-screw extruder is set at 140-180°C; take 30 parts of the combined masterbatch and compound 70 parts of polysuccinic acid-butylene adipate The ester is melt-extruded and granulated by a twin-screw extruder at 140-180°C to obtain composite particles; the composite particles are blown into film / injection molded strips at a temperature of 140-180°C.

[0044] The tensile strength, elongation at break, right-angle tear strength and absorbance of the degradable film that embodiment 3 obtains are tested, and test data is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com