100% solid content protective UV-curable coating composition and its coating and application

A composition and solid content technology, applied in coatings, polyether coatings, epoxy resin coatings, etc., can solve the problems of restricting formula design and use, low viscosity, etc., and achieve fast curing characteristics, high dirt resistance, Effect of good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

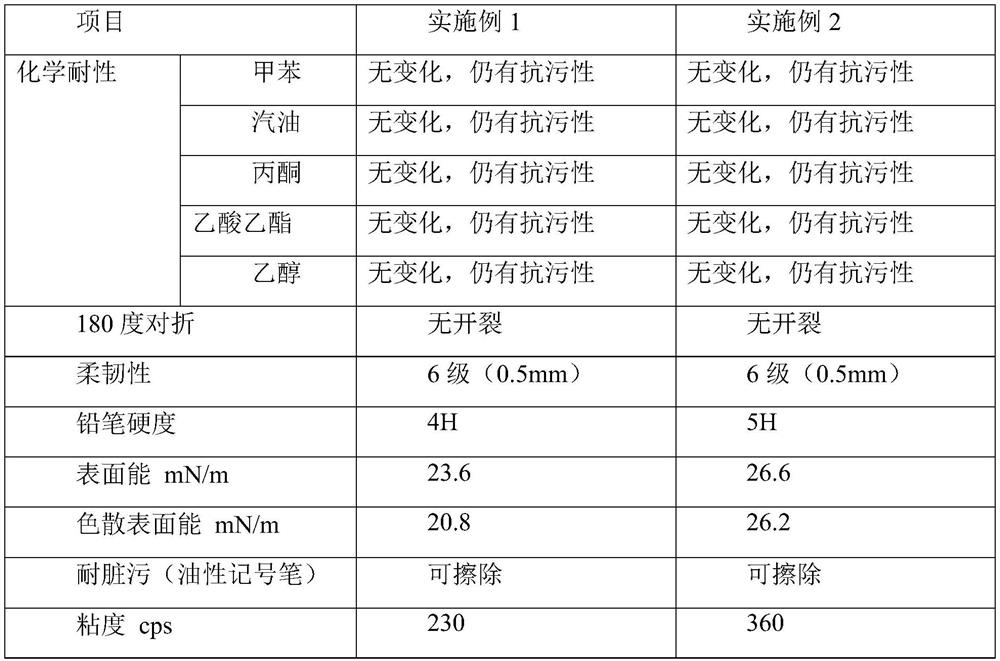

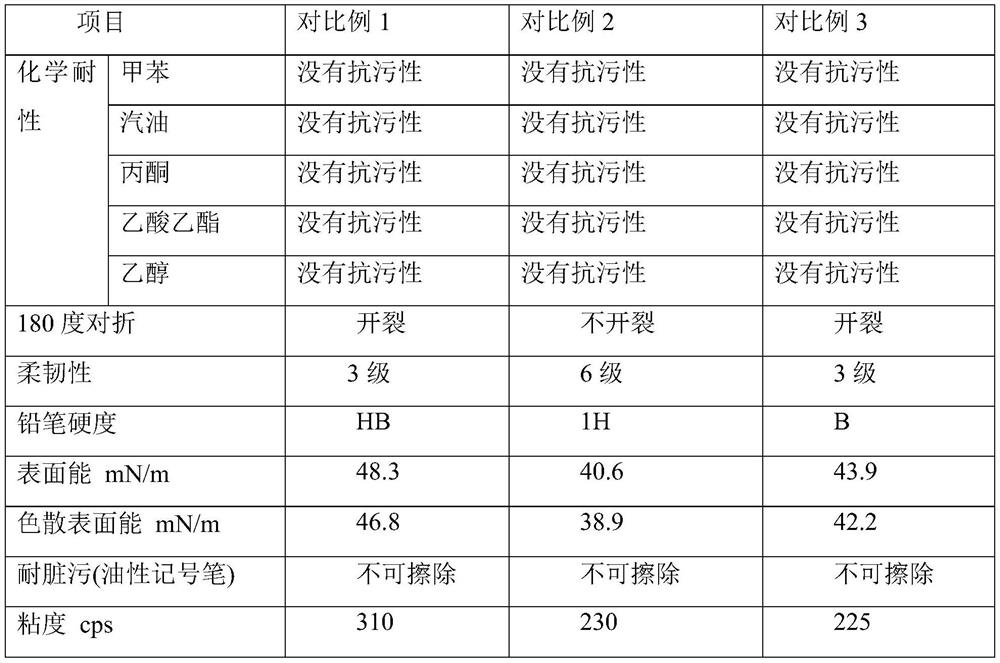

Examples

Embodiment 1

[0084] This embodiment is illustrative of the protective ultraviolet curable coating composition of the present invention, wherein each component and its content are shown in Table 1:

[0085] Table 1

[0086] Component Card or abbreviation Weight percentage% Cooling component without hydroxyl groups 421P 63 Cooling component without hydroxyl groups DVE-3 6 Hydroxylol-containing cationic cured component Hbve 17 Free-based curing component PU6510 6 Fluorine free radical curing component KL-760UVR 1 Free radical curing component EB1360 1 Cationic photoinitiator I250 3 Free-based photoinitiator DETX 3

[0087] As a result, a protective ultraviolet photocurable coating composition was obtained.

Embodiment 2

[0089] This embodiment is illustrative of the protective ultraviolet curable coating composition of the present invention, wherein each component and its content are shown in Table 2:

[0090] Table 2

[0091] Component Grades and manufacturers Weight percentage% Cooling component without hydroxyl groups U-9100A 40 Cooling component without hydroxyl groups 421P 31 Hydroxylol-containing cationic cured component OXT101 10 Free-based curing component E522 4 Fluorine free radical curing component RS90 1 Free radical curing component EB350 1 Cationic photoinitiator 1176 4 Free-based photoinitiator 184 2 Extinction E-1009 6 Additives, defoamers Airex900 0.3 Additives, wetting dispersant Dispers685 0.3 Additives, leveling agents GLIDE410 0.3 Additives, UV stabilizers Genorad * 16

[0092] As a result, a protective ultraviolet photocurable coating composition was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com