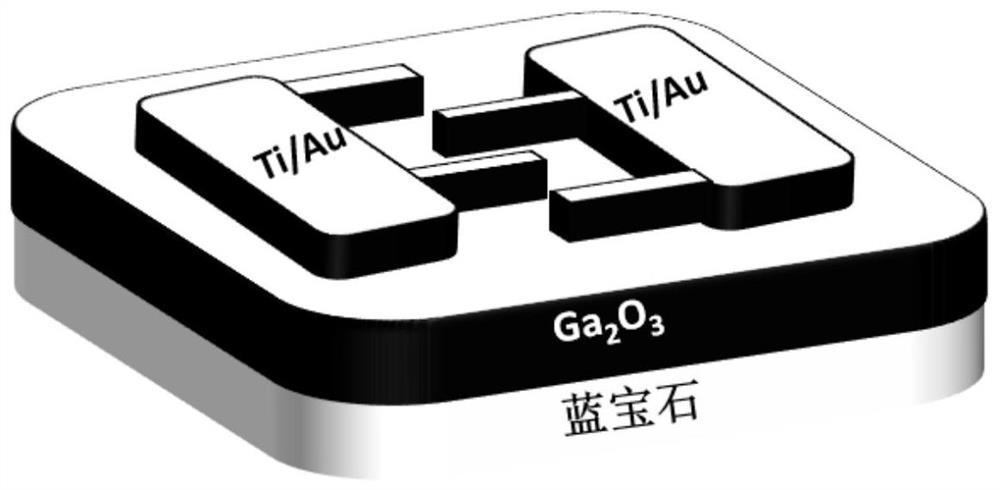

A heteroepitaxial ga 2 o 3 Preparation method of thin film deep ultraviolet photodetector

A technology of heterogeneous epitaxy and electrical detectors, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as high reaction temperature, complicated process, and low utilization rate of raw materials, and achieve the effects of reducing production costs and simplifying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1, under the growth condition of 300°C, Ga 2 o 3 Deep ultraviolet photodetector.

[0029] Step 1, preparing an aqueous precursor solution.

[0030] Take 0.592g of gallium acetylacetonate solid powder, 80mL of deionized water, and add 0.8ml of hydrochloric acid to dissolve it in deionized water, and dissolve the gallium acetylacetonate solid powder in deionized water hydrochloric acid solution to make a concentration of 0.02mol / L. Gallium acetonate precursor aqueous solution.

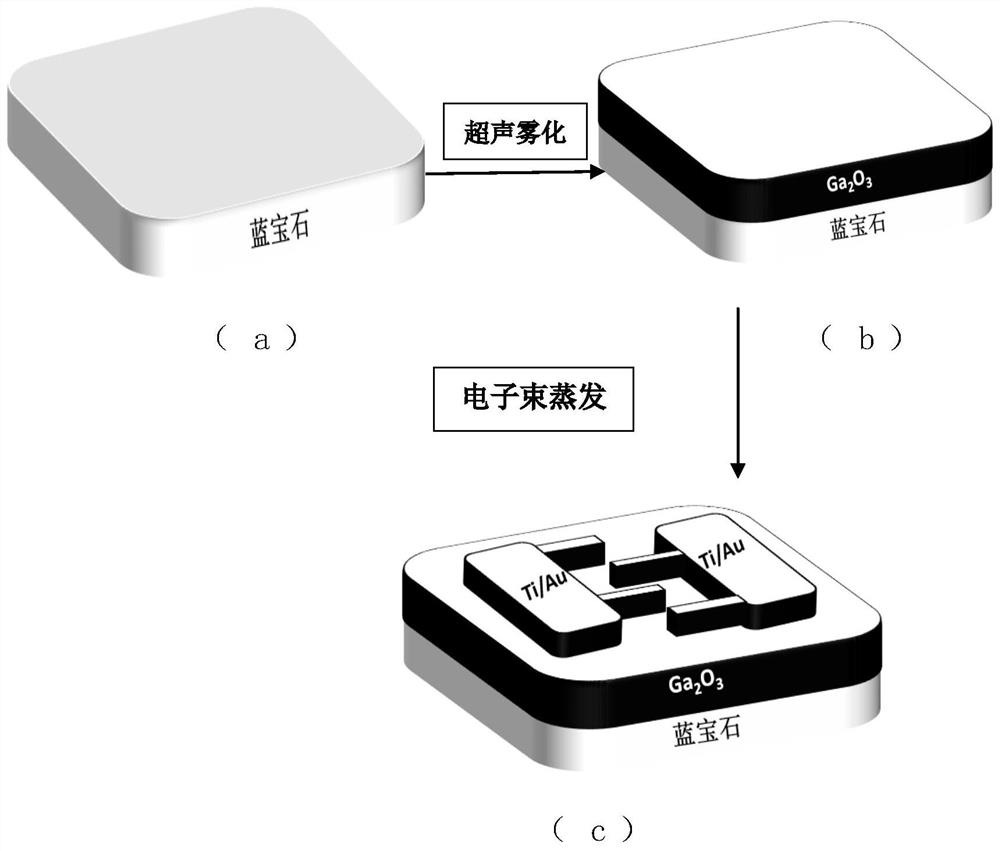

[0031] Step 2, cleaning the sapphire substrate, such as figure 2 (a).

[0032] Select the sapphire containing C face (0001) as the substrate, and clean it as follows:

[0033] Ultrasonic immersion in acetone solution for 10 minutes, then ultrasonic immersion in ethanol solution for 10 minutes, and finally ultrasonic immersion in deionized water for 10 minutes to complete the cleaning of the sapphire substrate.

[0034] Step 3, grow Ga 2 o 3 film, such as figure 2 (b).

[0035] ...

Embodiment 2

[0040] Example 2, making Ga with a thickness of 500nm under the growth condition of 550°C 2 o 3 Deep ultraviolet photodetector.

[0041] Step 1, take 1.48g of gallium acetylacetonate solid powder, 80mL of deionized water, and add 0.8ml of hydrochloric acid to dissolve in deionized water, and dissolve the gallium acetylacetonate solid powder in deionized water hydrochloric acid solution to make a concentration of 0.05mol / Aqueous solution of gallium acetylacetonate precursor in L.

[0042] Step 2, the specific implementation of this step is the same as step 2 of embodiment 1, such as figure 2 (a).

[0043] Step 3: Add the gallium acetylacetonate precursor aqueous solution to an ultrasonic nebulizer with a frequency of 1.7 MHz and atomize it into a gas, and transport the atomized gas to the reaction furnace through nitrogen. The carrier gas rate is 4 L / min, and the reaction furnace is set to The reaction temperature is 550°C, and the reaction time is 50 minutes. The atomize...

Embodiment 3

[0046] Example 3, making a Ga with a thickness of 2000nm under the growth condition of 800°C 2 o 3 Deep ultraviolet photodetector.

[0047] Step A, take 5.92 g of gallium acetylacetonate solid powder, 80 mL of deionized water, and add 0.8 ml of hydrochloric acid to dissolve in deionized water, and dissolve the gallium acetylacetonate solid powder in deionized water hydrochloric acid solution to make a concentration of 0.2 mol / Aqueous solution of gallium acetylacetonate precursor in L.

[0048] Step B, cleaning sapphire substrate: the specific implementation of this step is the same as step 2 of embodiment 1, as figure 2 (a).

[0049] Step C, adding the gallium acetylacetonate precursor aqueous solution to an ultrasonic nebulizer with a frequency of 1.7 MHz to atomize it into a gas, and transport the atomized gas to the reaction furnace through oxygen, the carrier gas rate is 8 L / min, and the reaction furnace is set to The reaction temperature is 800°C, and the reaction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com