Flowerlike manganese dioxide/carbon composite material and preparation method and application thereof

A technology of carbon composite materials and manganese dioxide, which is applied in the direction of secondary batteries, electrochemical generators, active material electrodes, etc., can solve the problems of unfavorable industrial production, complex composite process, poor stability, etc., to achieve full reaction, Simple process and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

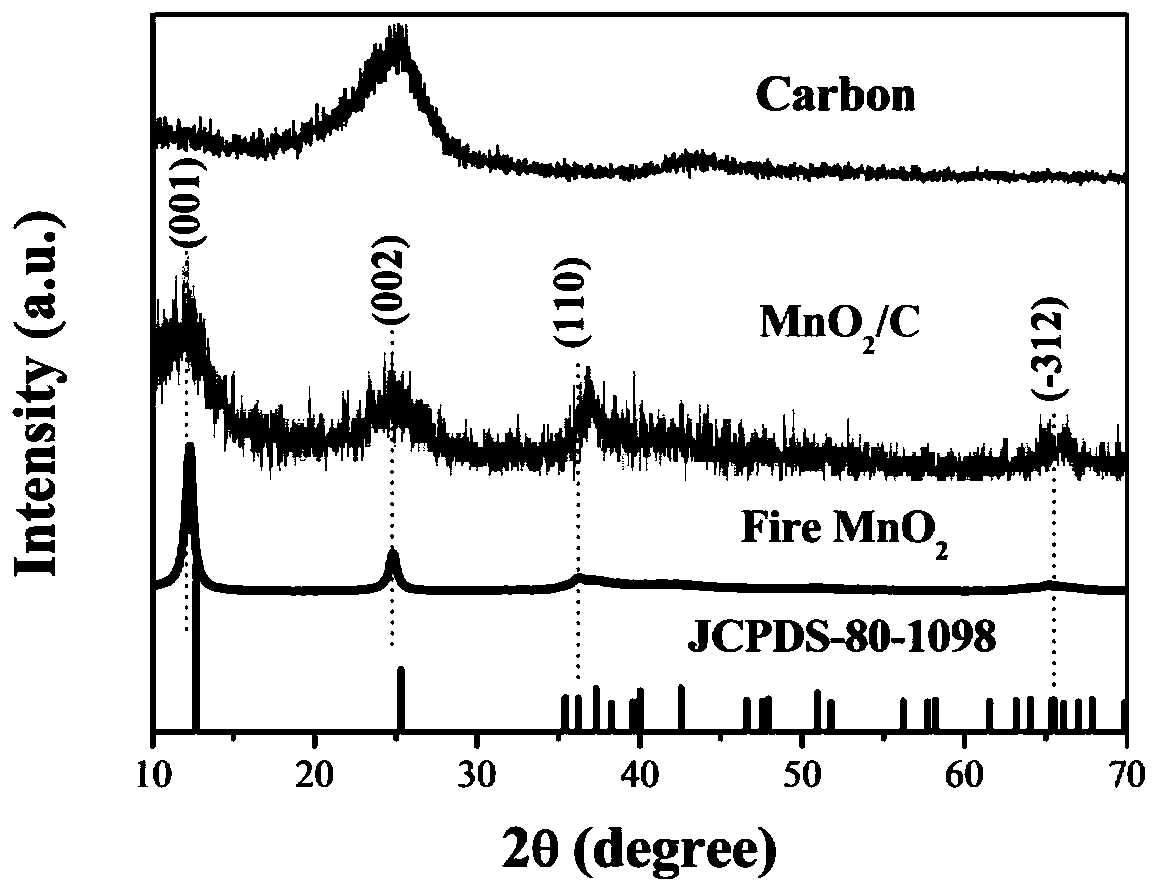

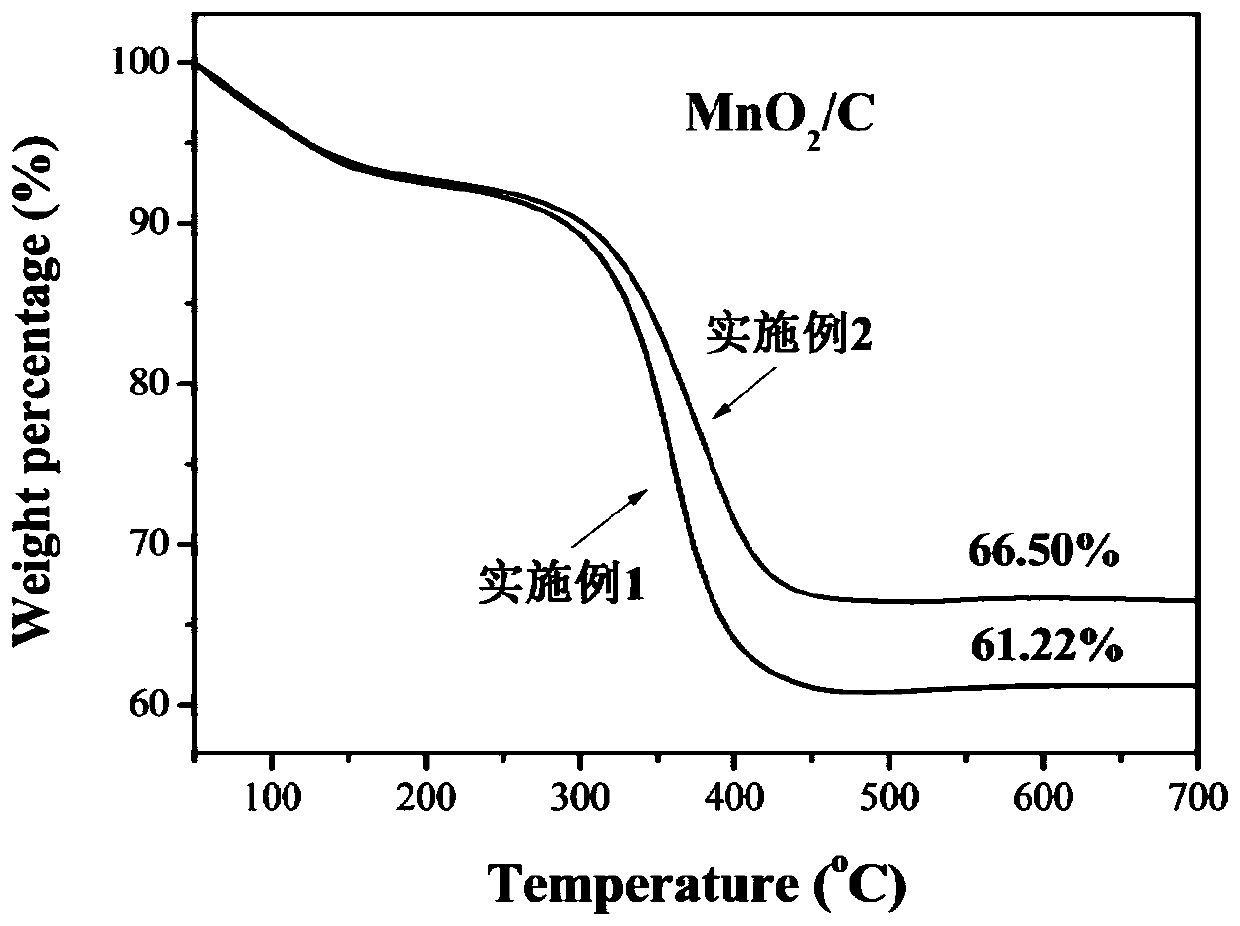

[0040] This embodiment provides a flower-shaped manganese dioxide / carbon composite material, which is prepared through the following process.

[0041] To the 200mL5mmol / L H 2 SO 4 Add 1 g of Super P to the glass bottle of the solution and ultrasonicate for 30 minutes to form a dispersion. Then add 200mL 0.2mol / L KMnO to the above dispersion 4 The aqueous solution was mixed uniformly and reacted with magnetic stirring at 80°C in an oil bath for 2 hours. After cooling, it was filtered and washed with deionized water three times, and dried at 90°C for 24 hours to obtain a manganese dioxide / carbon composite material.

Embodiment 2

[0043] This embodiment provides a flower-shaped manganese dioxide / carbon composite material, which is prepared through the following process.

[0044] Add 1 g of acetylene black to a glass bottle containing 200 mL of 10 mmol / L HCl solution and ultrasonicate for 30 minutes to form a dispersion. Then add 200mL 0.1mol / L KMnO to the above dispersion 4 The aqueous solution was mixed uniformly and reacted with magnetic stirring in an oil bath at 90°C for 3 hours. After cooling, it was filtered and washed with deionized water for 3 times, and air-dried at 90°C for 24 hours to obtain a manganese dioxide / carbon composite material.

Embodiment 3

[0046] This embodiment provides a flower-shaped manganese dioxide / carbon composite material, which is prepared through the following process. Add 3.2 g of Super P to a glass bottle containing 200 mL of 10 mmol / L HCl solution and ultrasonicate for 30 min to form a dispersion. Then add 200mL 0.1mol / L KMnO to the above dispersion 4 The aqueous solution was mixed uniformly and reacted with magnetic stirring in an oil bath at 90°C for 3 hours. After cooling, it was filtered and washed with deionized water three times, and dried at 90°C for 24 hours to obtain a manganese dioxide / carbon composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com