Preparation method of PdRh alloy electrocatalyst for fuel cell and application

An electrocatalyst and fuel cell technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve problems such as low yield and complexity, and achieve the effects of less energy consumption, accelerated release, and economical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

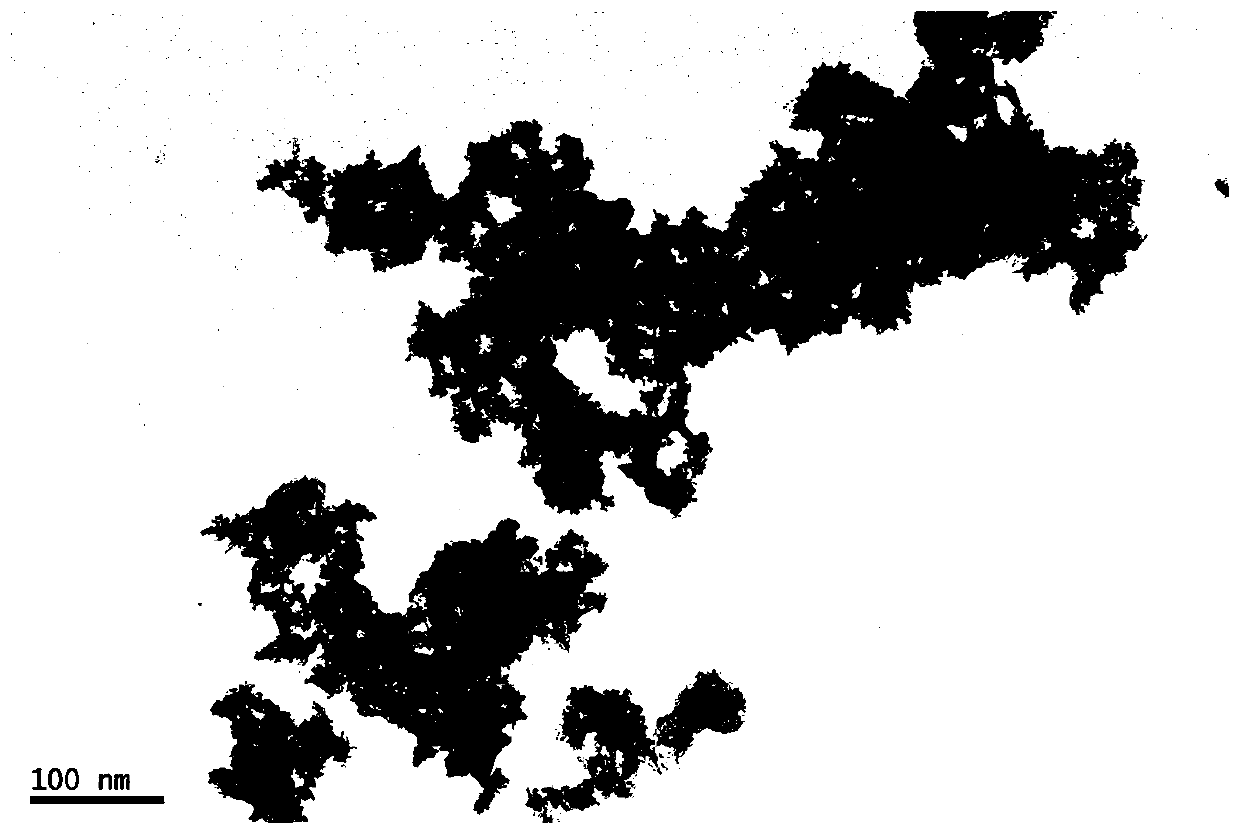

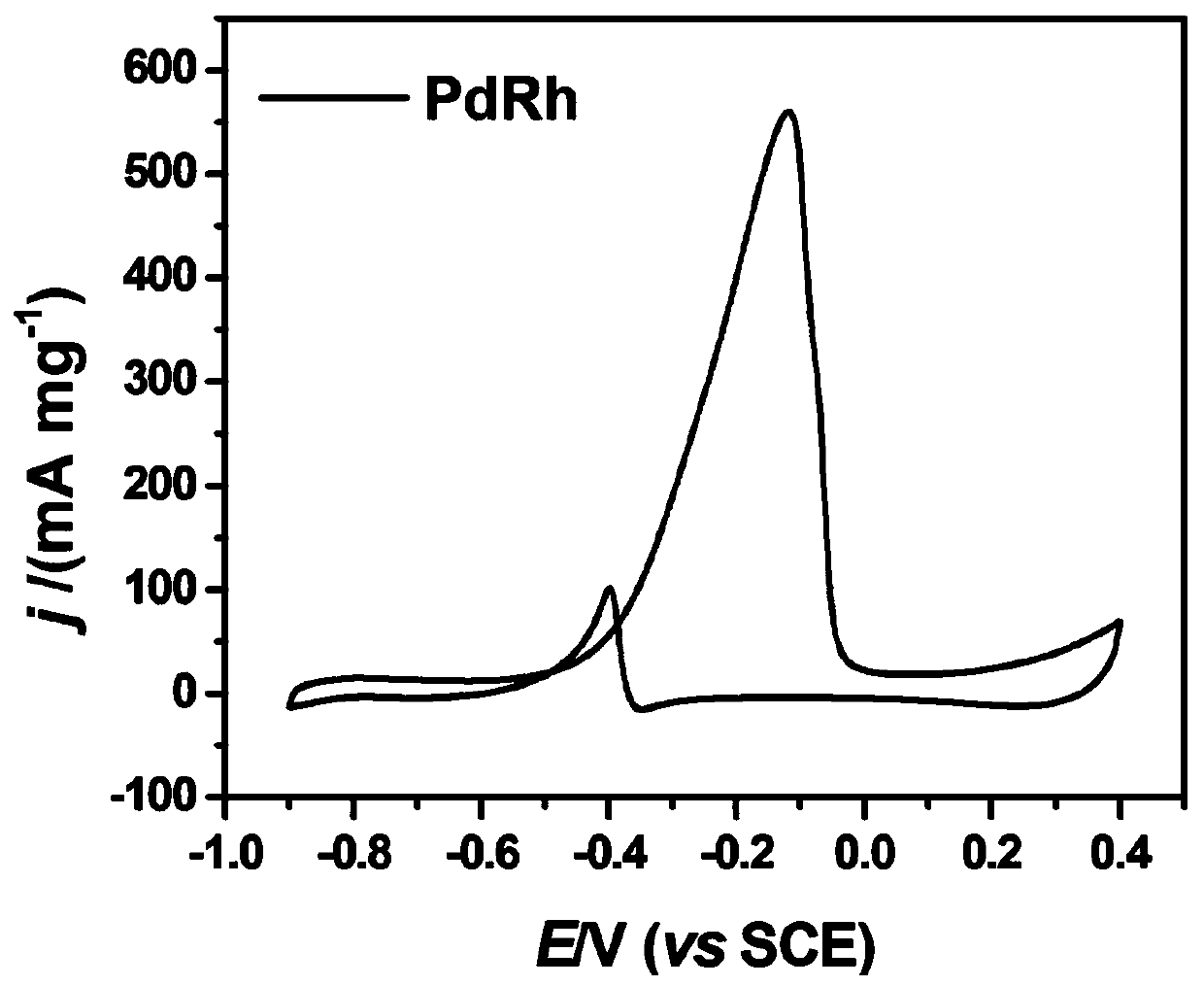

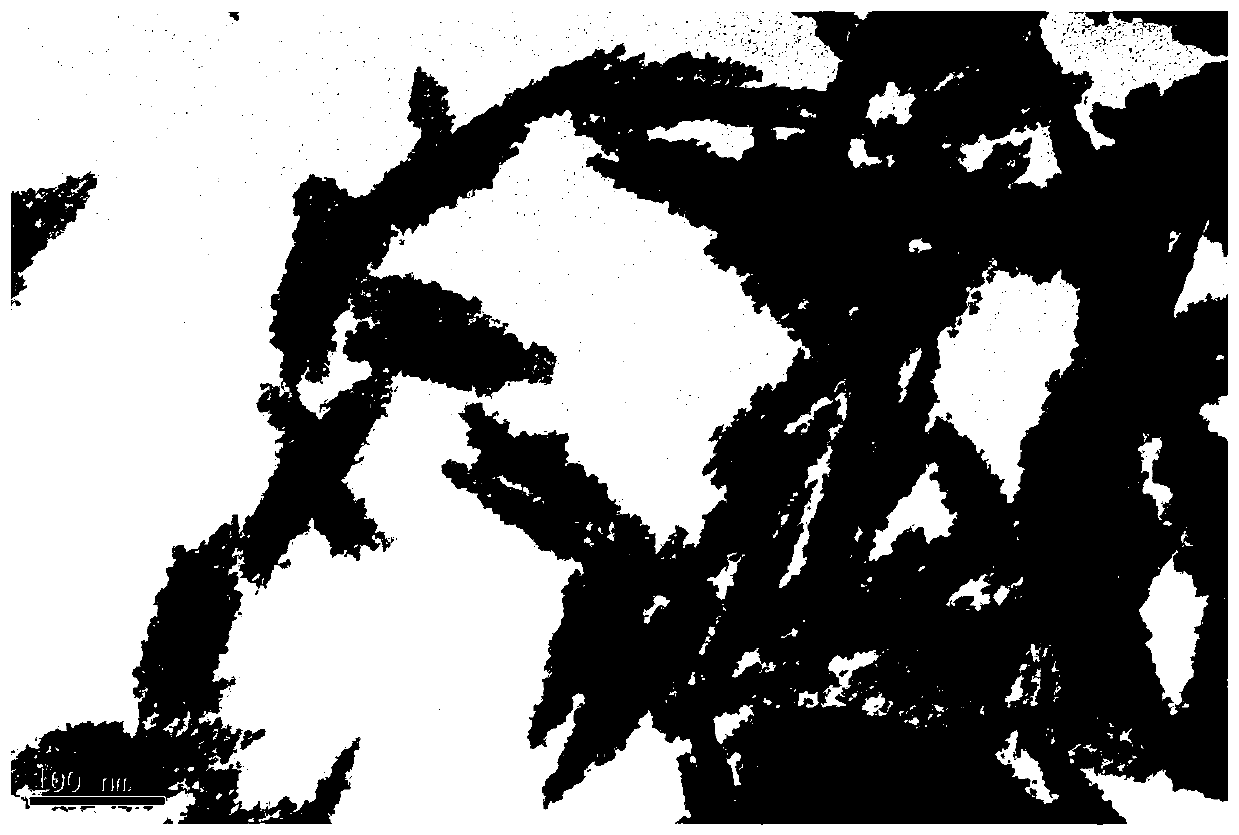

Image

Examples

Embodiment 1

[0037] (1) Weigh 0.5 g of P123 into a 50 ml beaker, add 25 ml H 2 O, ultrasonically stir to dissolve, pipette 0.1ml of 0.5M PEI solution into the mixed solution with a pipette gun, after ultrasonically mixing evenly, then add 2ml of 37% formaldehyde solution, and carry out magnetic stirring with a certain intensity at room temperature.

[0038] (2) Weigh 9.79 mg K respectively 2 PdCl 4 and 6.28 mg RhCl 3 to a 25 ml beaker, add 15 ml H to the beaker 2 O, after ultrasonic mixing, use a constant pressure dropping funnel to control the flow rate of one drop per second to drop into the mixed solution A, and carry out magnetic stirring at a certain intensity at room temperature, after stirring for 0.5 h.

[0039] (3) Transfer the mixed solution to a polytetrafluoroethylene reactor, maintain the oven reaction temperature at 120 °C, and keep the temperature for 12 h.

[0040] (4) Naturally cool to room temperature, keep standing, and centrifuge the black turbid liquid obtained aft...

Embodiment 2

[0045] Weigh 0.5 g of P123 into a 50 ml beaker, add 25 ml H 2 O, ultrasonically stir to dissolve, pipette 0.1ml of 0.5M PEI solution into the mixed solution with a pipette gun, after ultrasonically mixing evenly, then add 2ml of 37% formaldehyde solution, and carry out magnetic stirring with a certain intensity at room temperature.

[0046] (2) Weigh 9.79 mg K respectively 2 PdCl 4 and 2.10 mg RhCl 3 into a 25 ml beaker, add 15 ml H to the beaker 2 O, after ultrasonic mixing, use a constant pressure dropping funnel to control the flow rate of one drop per second to drop into the mixed solution A, and carry out magnetic stirring at a certain intensity at room temperature, after stirring for 0.5 h.

[0047] (3) Transfer the mixed solution to a polytetrafluoroethylene reactor, maintain the oven reaction temperature at 120 °C, and keep the temperature for 12 h.

[0048] (4) Naturally cool to room temperature, keep standing, and centrifuge the black turbid liquid obtained after...

Embodiment 3

[0053] (1) Weigh 0.5 g of P123 into a 50 ml beaker, add 25 ml H 2 O, ultrasonic stirring to dissolve, pipette 0.1ml 0.5M PEI solution into the mixed solution with a pipette gun, after ultrasonic mixing evenly, then add 2ml 37% formaldehyde solution, and carry out magnetic stirring with a certain intensity at room temperature.

[0054] (2) Weigh 9.79 mg K respectively 2 PdCl 4 and 18.83 mg RhCl 3 into a 25 ml beaker, add 15 ml H to the beaker 2 O, after ultrasonic mixing, use a constant pressure dropping funnel to control the flow rate of one drop per second to drop into the mixed solution A, and carry out magnetic stirring at a certain intensity at room temperature, after stirring for 0.5 h.

[0055] (3) Transfer the mixed solution to a polytetrafluoroethylene reactor, maintain the oven reaction temperature at 120 °C, and keep the temperature for 12 h.

[0056] (4) Naturally cool to room temperature, keep standing, and centrifuge the black turbid liquid obtained after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com