Quantitatively treating method by diamond anvil cell

A diamond anvil and processing technology, which is applied in the application of ultra-high pressure process, chemical/physical process, physical/chemical process catalyst, etc., can solve the problems of low efficiency, high power consumption, low power consumption, etc., and achieve increased Scale, low power consumption, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

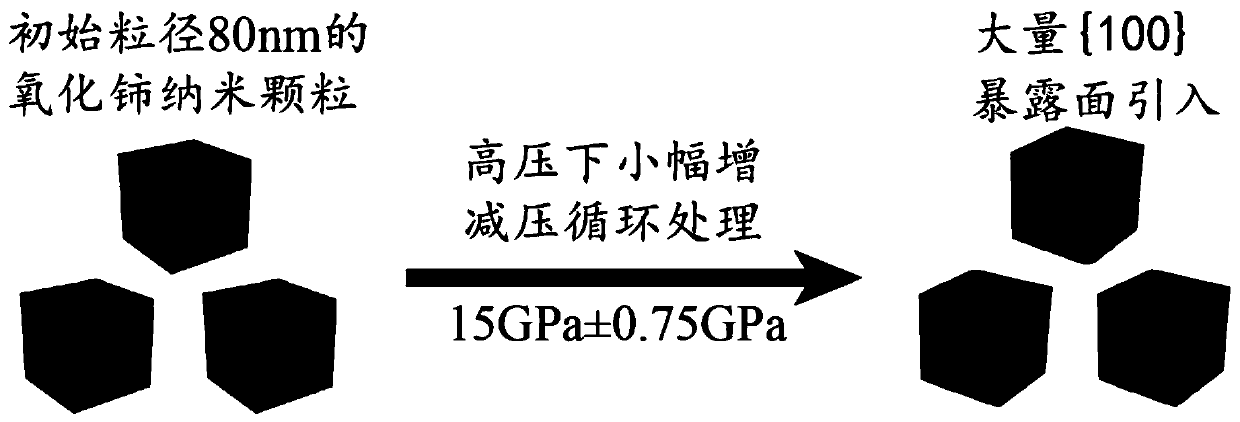

[0022] Such as figure 1 As shown, the cerium oxide nanoparticles with an initial average particle size of 80nm are selected; under normal temperature conditions, a diamond anvil with a diameter of 300 microns is used to hold the cerium oxide nanoparticles with an average particle size of 80nm; the holding pressure is 15GPa± 0.75GPa; apply a small increase in pressure cycle or decompression cycle, the range of increase and decrease is ± 5%; after 100 cycles, use transmission electron microscopy to characterize the exposed crystal planes, and the characterization results show that before high pressure treatment, After that, the exposed surface of {100} in the sample increased significantly, which proved that the high-pressure treatment process effectively increased the exposed surface of {100}; the catalytic efficiency experiment was carried out using the treated cerium oxide nanoparticles, and the catalytic efficiency in the treated sample was improved. 15%; the nano-cerium oxi...

Embodiment 2

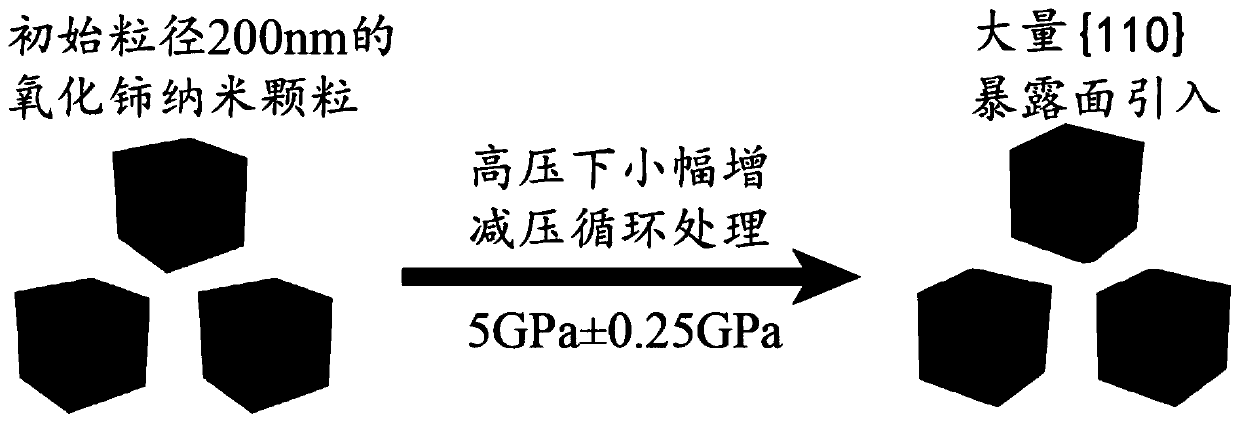

[0024] Such as figure 2 As shown, the cerium oxide nanoparticles with an initial average particle size of 200nm are selected; under normal temperature conditions, a diamond anvil with a diameter of 300 microns is used to hold the cerium oxide nanoparticles with an average particle size of 80nm; the holding pressure is 5GPa± 0.25GPa; apply a small increase in pressure cycle or decompression cycle, the range of increase and decrease is ± 5%; after 100 cycles, use transmission electron microscopy to characterize the exposed crystal planes, and the characterization results show that before high pressure treatment, After that, the exposed surface of {110} in the sample increased significantly, which proved that the high-pressure treatment process effectively increased the exposed surface of {110}; the catalytic efficiency experiment was carried out using the treated cerium oxide nanoparticles, and the catalytic efficiency in the treated sample was improved. 7%; the nano-cerium oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com