Iron-sulfur coupled catalyst capable of efficiently degrading high-concentration phenol, and preparation method and application of catalyst

A catalyst, high-concentration technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of low degradation efficiency of organic pollutants, low efficiency of Fenton degradation of pollutants, and iron ion dissolution rate. Low problems, to achieve the effect of easier control of the operation process, low cost, and reduced process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of an iron-sulfur coupling catalyst capable of efficiently degrading high-concentration phenol:

[0033] 1) Synthetic goethite;

[0034] 2) Put ferrous sulfate (40~48%) into a 150 mL conical flask, then use a graduated cylinder to measure deionized water (30~50 mL) and add it to the conical flask. Use a magnetic stirrer to stir until the ferrous sulfate is completely dissolved;

[0035] 3) Add goethite (amount of 23~28%), continue to feed nitrogen and continue magnetic stirring for 10-60 min, so that the ferrous sulfate solution and goethite are evenly mixed;

[0036] 4) Add sodium sulfide (25-30%) solution, continue to pass nitrogen and continue magnetic stirring for 1 h, then centrifuge to remove the supernatant to obtain a solid, freeze-dry at -48°C for 48 h in a vacuum freeze-dryer to obtain Iron-sulfur coupling catalyst, referred to as GS material.

Embodiment 2

[0038] A preparation method of an iron-sulfur coupling catalyst capable of efficiently degrading high-concentration phenol:

[0039] 1) Synthetic goethite;

[0040] 2) Put ferrous chloride (30-40%) into a 150 mL conical flask, then use a graduated cylinder to measure deionized water (30-50 mL) and add it to the conical flask. Simultaneously use magnetic stirrer to stir until ferrous chloride is completely dissolved;

[0041] 3) Add goethite (amount of 23-28%), continue to feed nitrogen and continue magnetic stirring for 10-60 min, so that the ferrous chloride solution and goethite are evenly mixed;

[0042] 4) Add potassium sulfide solution (amount of 35-40%), continue to flow nitrogen and continue magnetic stirring for 1 h, then centrifuge to remove the supernatant to obtain a solid, freeze-dry at -48°C for 48 h in a vacuum freeze-dryer, and obtain Iron-sulfur coupling catalyst, referred to as GS material.

Embodiment 3

[0044] Preparation of goethite:

[0045] Weigh 50.0 g of Fe(NO 3 ) 3 9H 2 O put it in a 1000 mL plastic container and dilute it to 500 mL with deionized water, then weigh 20 g of NaOH, dissolve and dilute it with 100 mL of deionized water to make a working solution of 5 moL / L, and then add the solution containing Fe dropwise (NO 3 ) 3 9H 2 In a plastic container of O, adjust the pH of the mixed solution to about 12, seal the obtained thick suspension with a plastic wrap, and age it in a constant temperature oven at 70°C for 60 h, the reddish-brown flocculent iron-containing precipitate becomes Small brown particles were washed repeatedly with distilled water until neutral, and the viscous solid obtained after centrifuging to remove the supernatant was vacuum-dried at 60°C for 48 hours to obtain goethite.

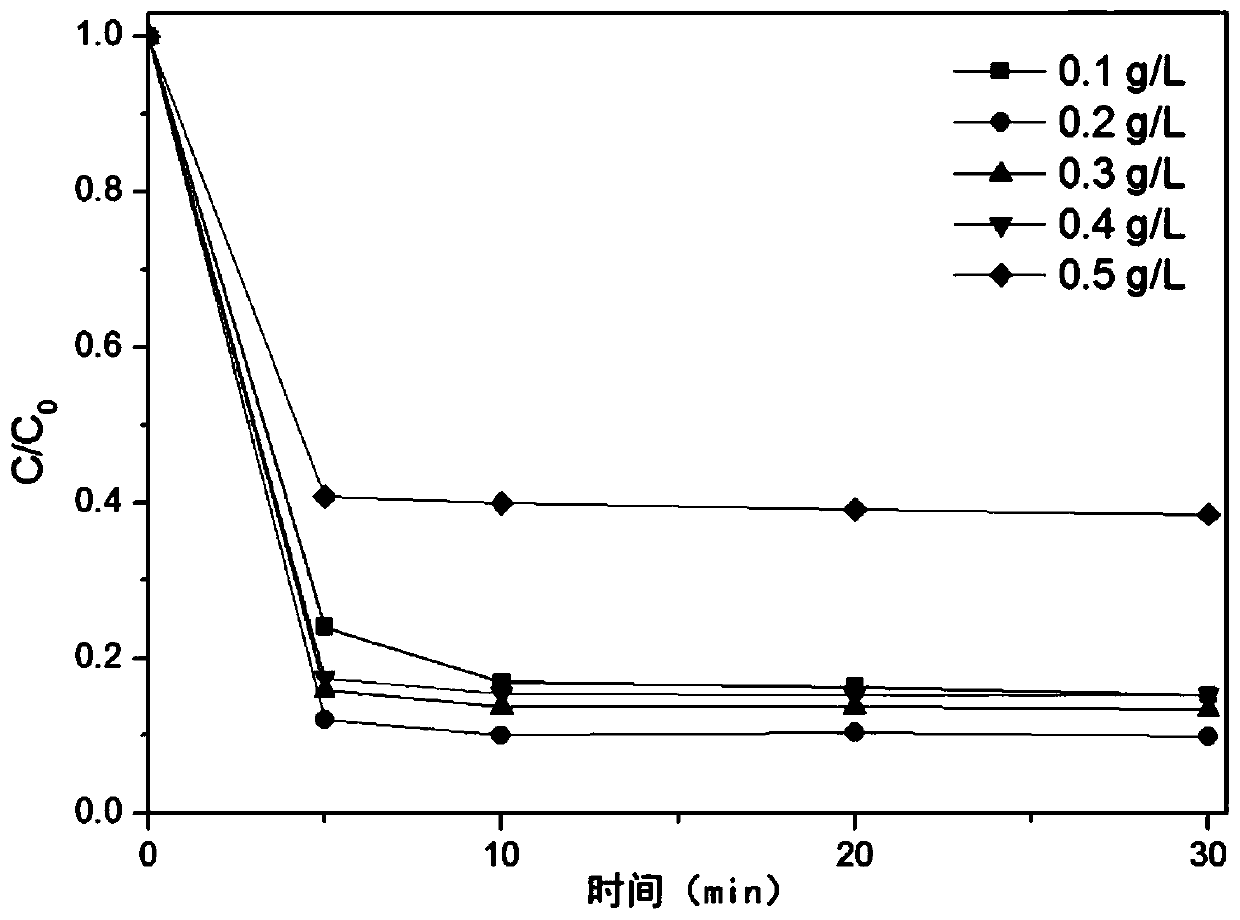

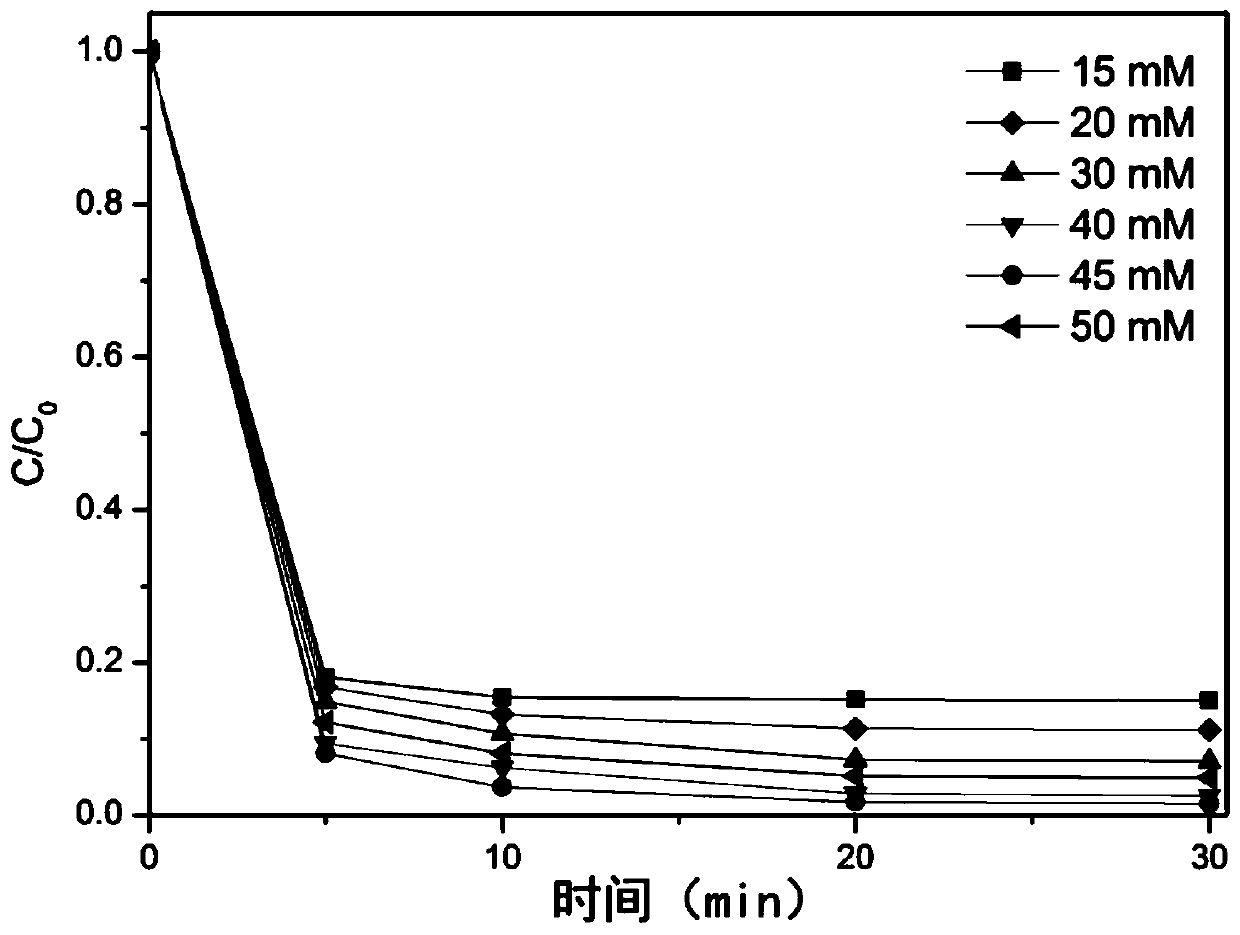

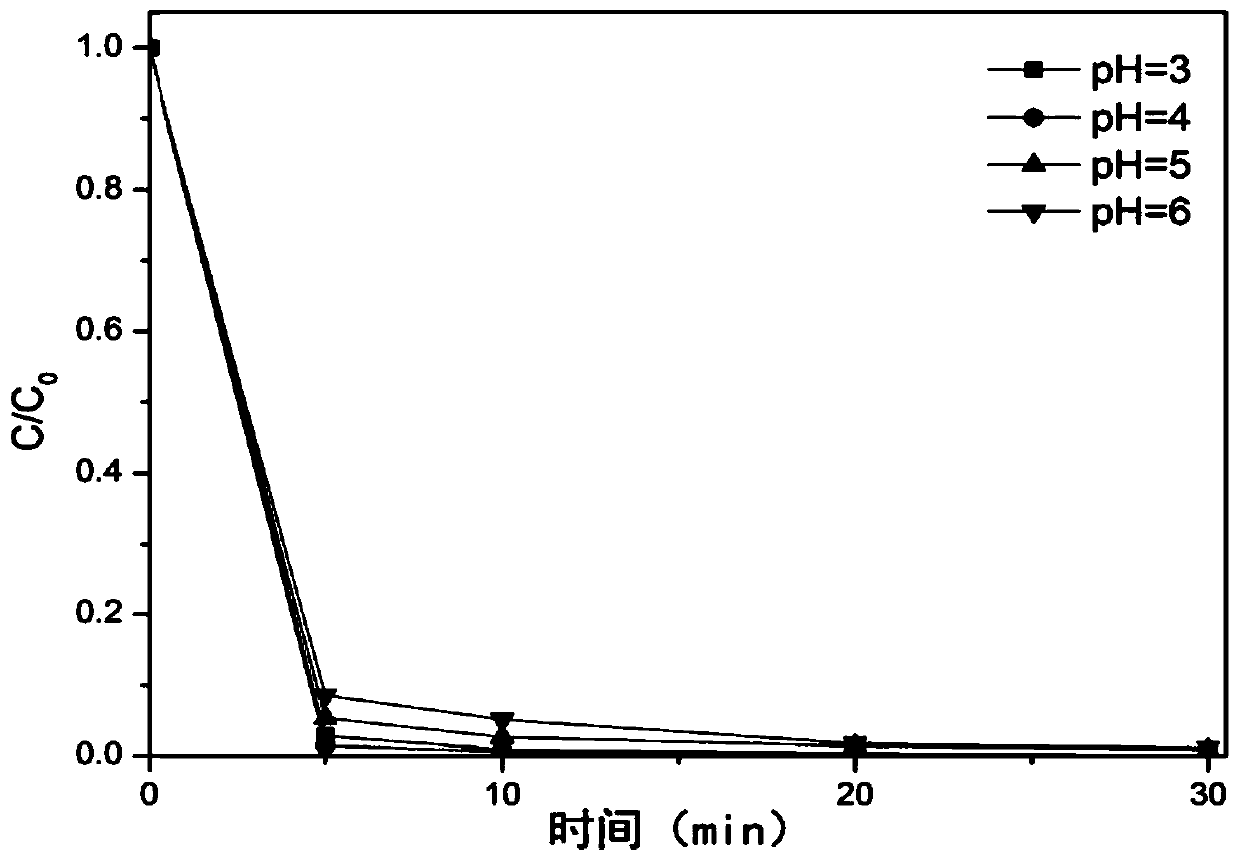

[0046] The steps of the method for degrading phenol are as follows: Take the prepared phenol solution (100-1000 mg / L) and add GS material (0.1-0.5 g / L), blow in nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com