Semipermeable membrane support body

A semi-permeable membrane and support technology, applied in the field of semi-permeable membrane supports, can solve problems such as insufficient and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

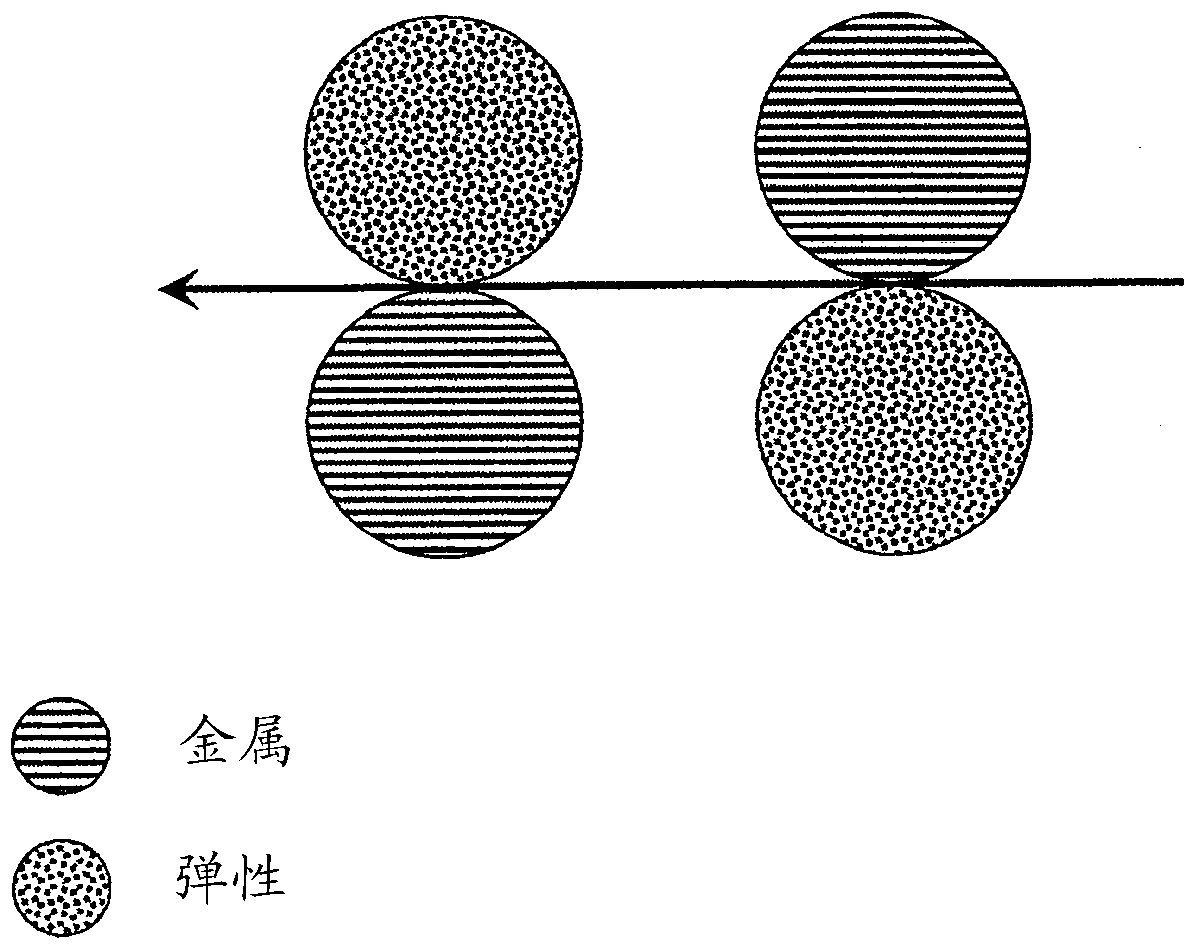

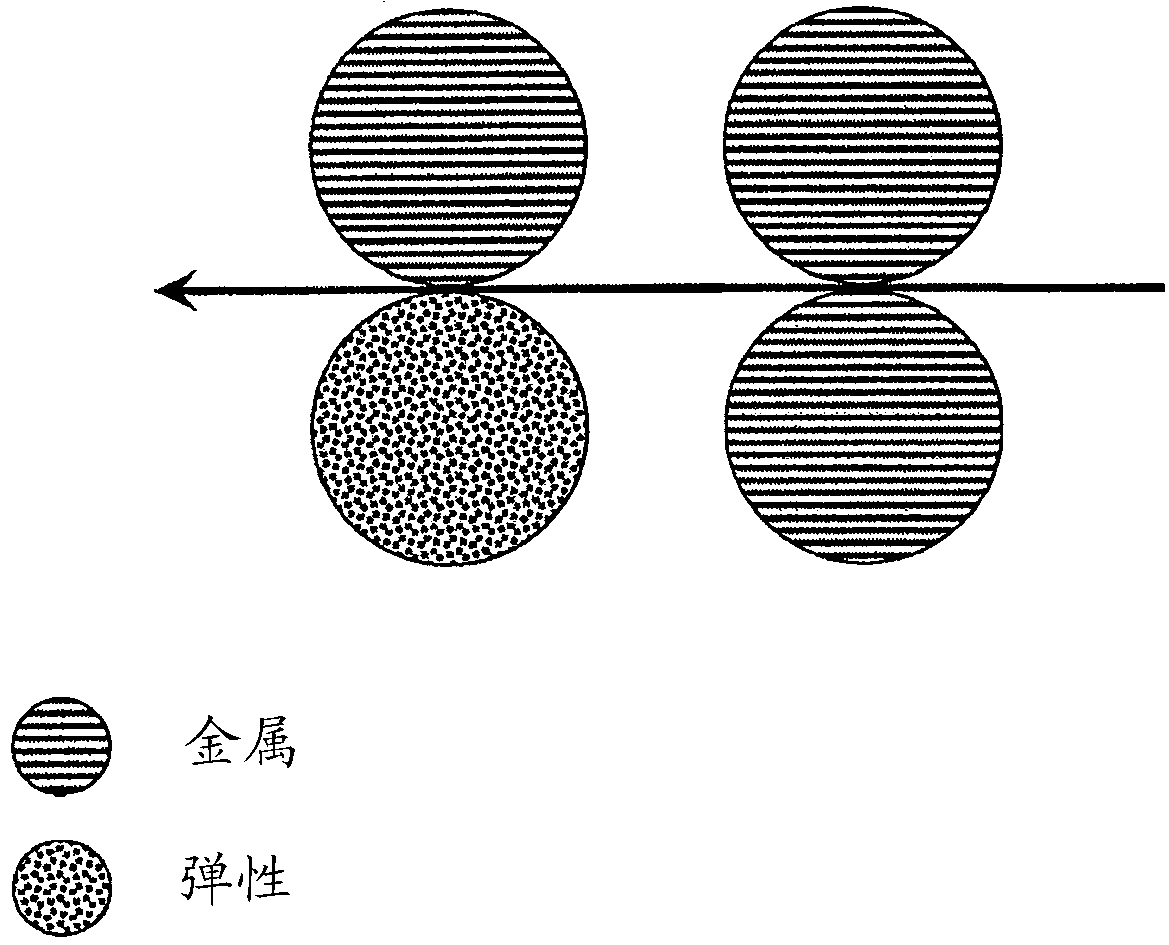

Method used

Image

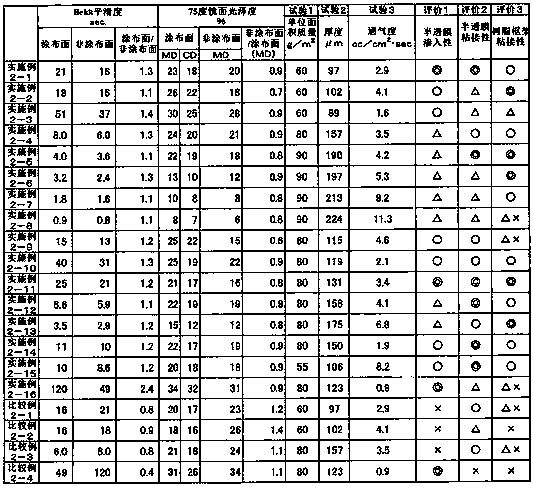

Examples

Embodiment 1-1

[0137] 100 parts by mass of PP / PE core-sheath fibers (average fiber diameter 10.8 μm, fiber length 5 mm) whose core component is polypropylene (melting point 165° C.) and sheath component is polyethylene (melting point 135° C.) are placed in the water of the pulper Dissociate and disperse, and stir slowly with a mixer to make a uniform slurry for papermaking. The papermaking slurry was made using a wet papermaking method using a cylinder paper machine, and dried with a hot air hood installed at the same time as a hot plate pressure bonding method set at 135°C, that is, a Yankee dryer, and simultaneously made PP / The sheath part of the PE core-sheath fiber is thermally melted and bonded to obtain a sheet, and the resulting sheet is rolled using a combination of a metal roll (heated) and a resin roll (non-heated) at a metal roll temperature of 100°C and a pressure of 100kN / m 1. Under the condition of a processing speed of 40 m / min, hot press processing was carried out in such a ...

Embodiment 1-2

[0139] Change the formula to 70 parts by mass of PP / PE core-sheath fiber (average fiber diameter 10.8 μm, fiber length 5 mm), 30 parts by mass of PP single fiber (average fiber diameter 11.0 μm, fiber length 5 mm). The same method as in Example 1-1 was used to obtain a semipermeable membrane support.

Embodiment 1-3

[0141] Change the recipe to 60 parts by mass of PP / PE core-sheath fiber (average fiber diameter 10.8 μm, fiber length 5 mm), 40 parts by mass of PP single fiber (average fiber diameter 11.0 μm, fiber length 5 mm). The same method as in Example 1-1 was used to obtain a semipermeable membrane support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com