A low calorific value high-strength cable support and its preparation method

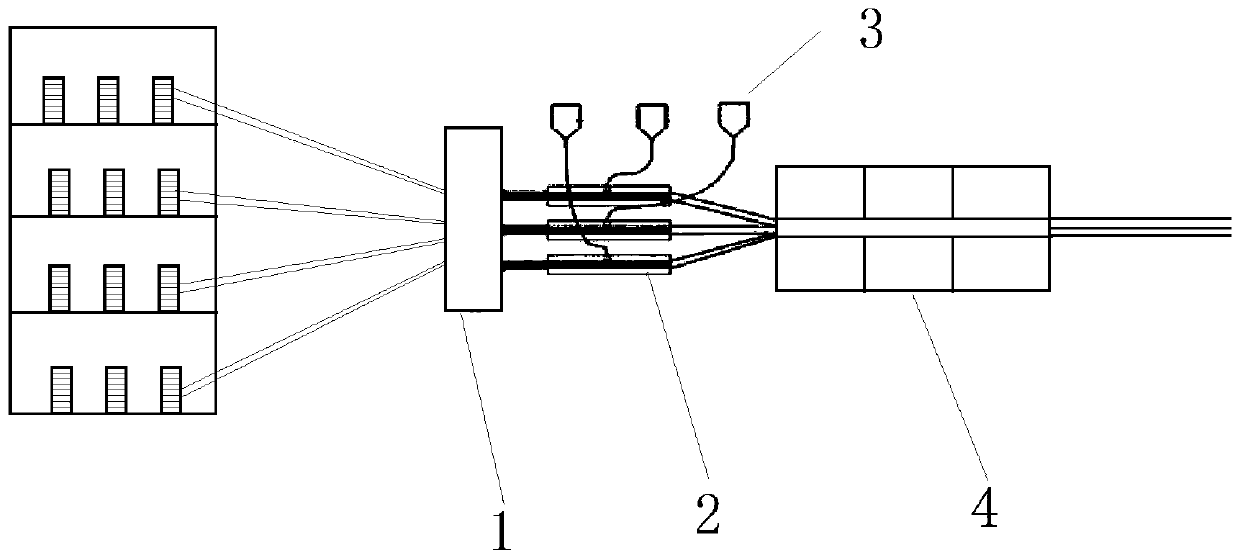

A cable support and high-strength technology, applied in the field of low calorific value and high-strength cable support and its preparation, can solve the problems of low strength, poor fire resistance, inconvenient assembly, etc. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

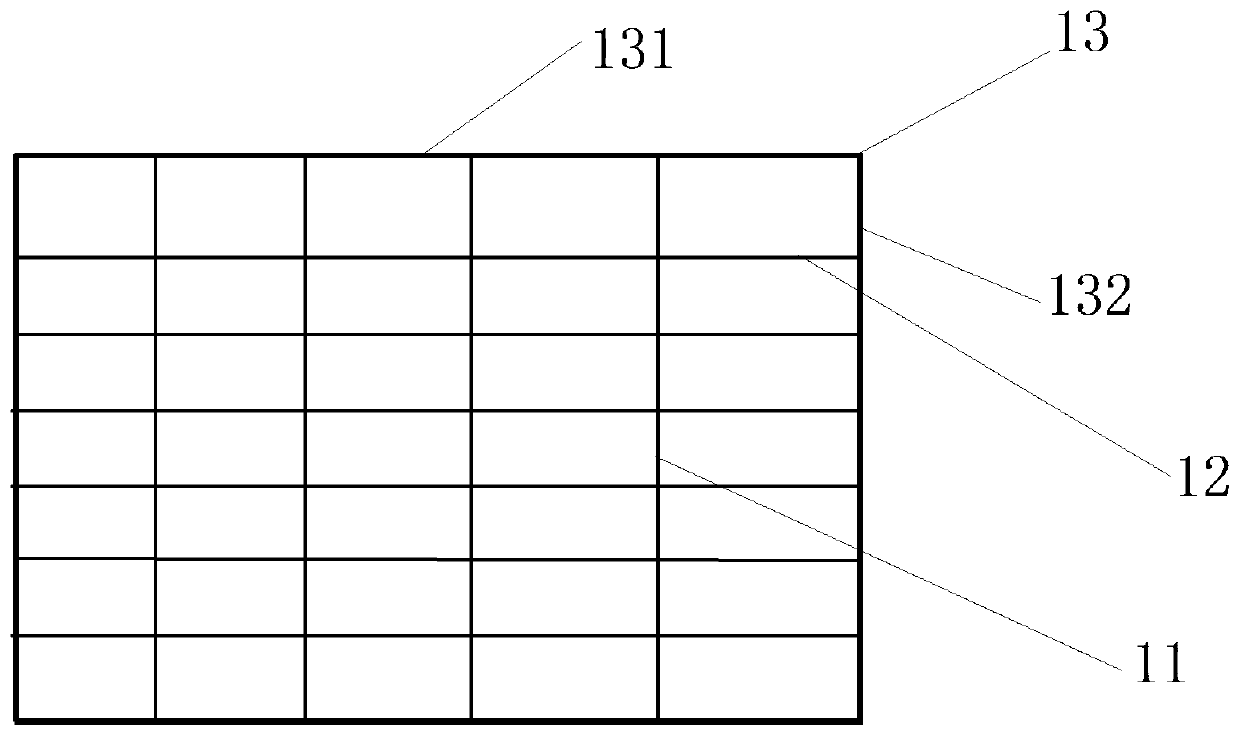

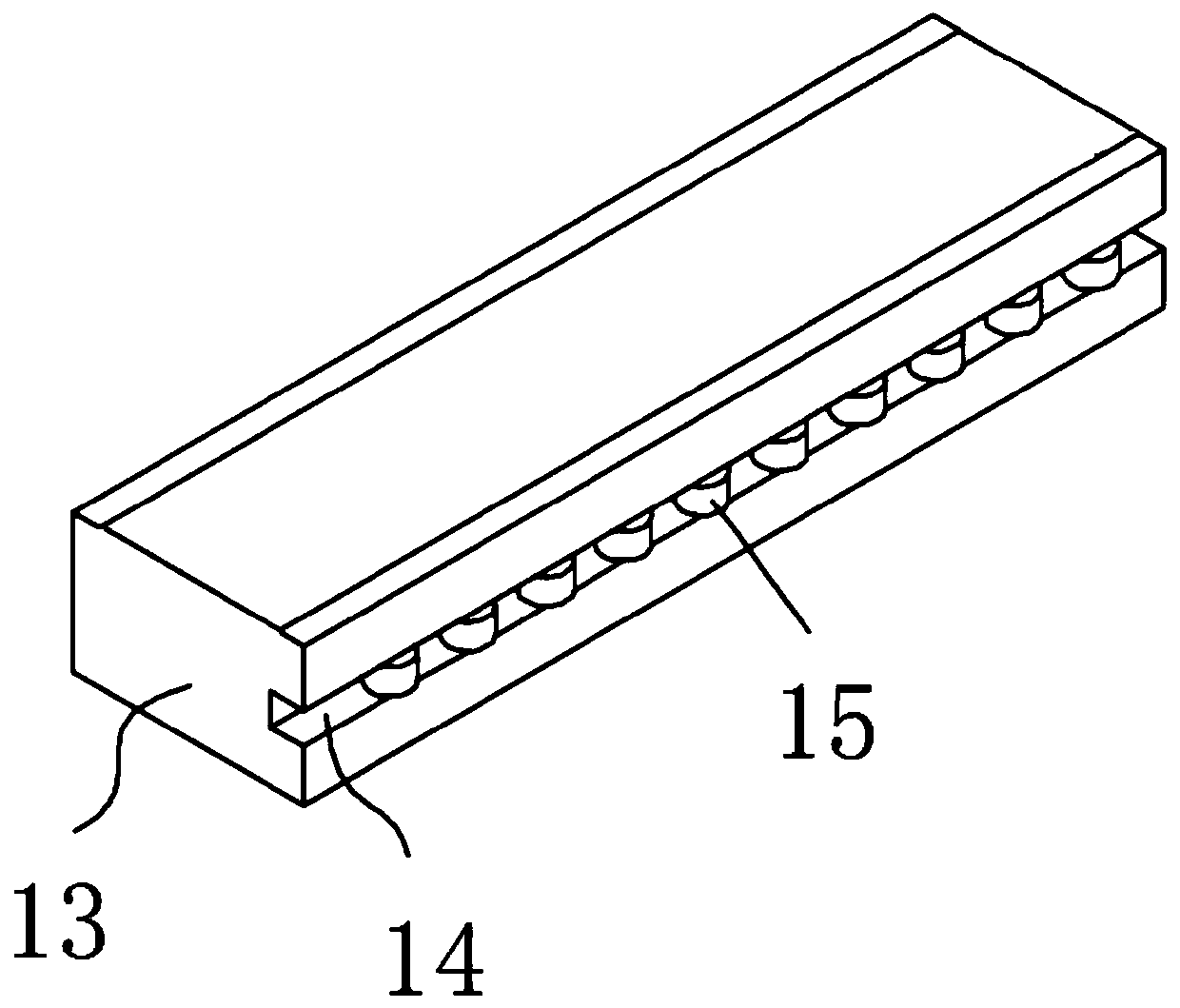

Method used

Image

Examples

preparation example Construction

[0047] Specifically, the present application provides a method for preparing a low thermal resistance high-strength cable support, the method comprising the steps of:

[0048] S1, preparing the base material;

[0049] S2, preparing the mixture: put 100 parts by weight of matrix material, 1-3 parts by weight of internal release agent and 30-60 parts by weight of inorganic powder into the stirring tank 3, stir evenly, and then add 1-2 parts of even Mixing agent, 30-60 parts by weight of inorganic powder, 3-5 parts of nano-montmorillonite, 1-3 parts of anti-ultraviolet agent and 5-10 parts by weight of chopped glass fiber, stir well to obtain the mixture;

[0050] S3, yarn application: pass the non-alkali continuous glass fiber through the dipping tank, so that the mixture is fully infiltrated with the non-alkali continuous glass fiber, and then extrude part of the mixture through the pressing roller, so that the total content of the glass fiber is between 70% and 75%. between; ...

Embodiment 1

[0126] A method for preparing a low calorific value high-strength cable support, said method comprising the steps of:

[0127] S1. Preparation of matrix material: Add 100 parts by weight of phenolic resin into the reaction kettle, stir and heat to 30°C, then add 3 parts by weight of silicone prepolymer and 1 part by weight of sodium dihydrogen phosphate, within 3 minutes Raise the temperature to 60°C and stir at 60°C for 10 minutes to obtain the matrix material;

[0128] S2, preparing the mixture: put 100 parts by weight of matrix material, 1 part by weight of internal release agent and 30 parts by weight of inorganic powder into the stirring tank, stir evenly, then add 1 part of coupling agent, 30 parts by weight of Inorganic powder, 3 parts of nano-montmorillonite, 1 part of anti-ultraviolet agent and 5 parts by weight of chopped glass fiber are stirred evenly to obtain the mixture;

[0129] S3, yarn application: pass the non-alkali continuous glass fiber through the dipping ...

Embodiment 2

[0136] A method for preparing a low calorific value high-strength cable support, said method comprising the steps of:

[0137] S1, preparation of matrix material: Add 100 parts by weight of phenolic resin into the reaction kettle, stir and heat to 50°C, then add 10 parts by weight of organosilicon prepolymer and 3 parts by weight of sodium dihydrogen phosphate at the same time, within 5min Raise the temperature to 60°C and stir at 60°C for 10 minutes to obtain the matrix material;

[0138] S2, preparing the mixture: put 100 parts by weight of matrix material, 3 parts by weight of internal release agent and 60 parts by weight of inorganic powder into the stirring tank, stir evenly, then add 2 parts of coupling agent, 60 parts by weight of Inorganic powder, 5 parts of nano-montmorillonite, 3 parts of anti-ultraviolet agent and 10 parts by weight of chopped glass fibers are stirred evenly to obtain the mixture;

[0139] S3, yarn application: pass the non-alkali continuous glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com